Vertical preflex device for rib cold bending unit

A technology of cold bending machine and rib, applied in the directions of transportation and packaging, hull parts, hull, etc., can solve the problems of troublesome operation, complicated mechanism, difficult maintenance, etc., and achieve the effect of simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

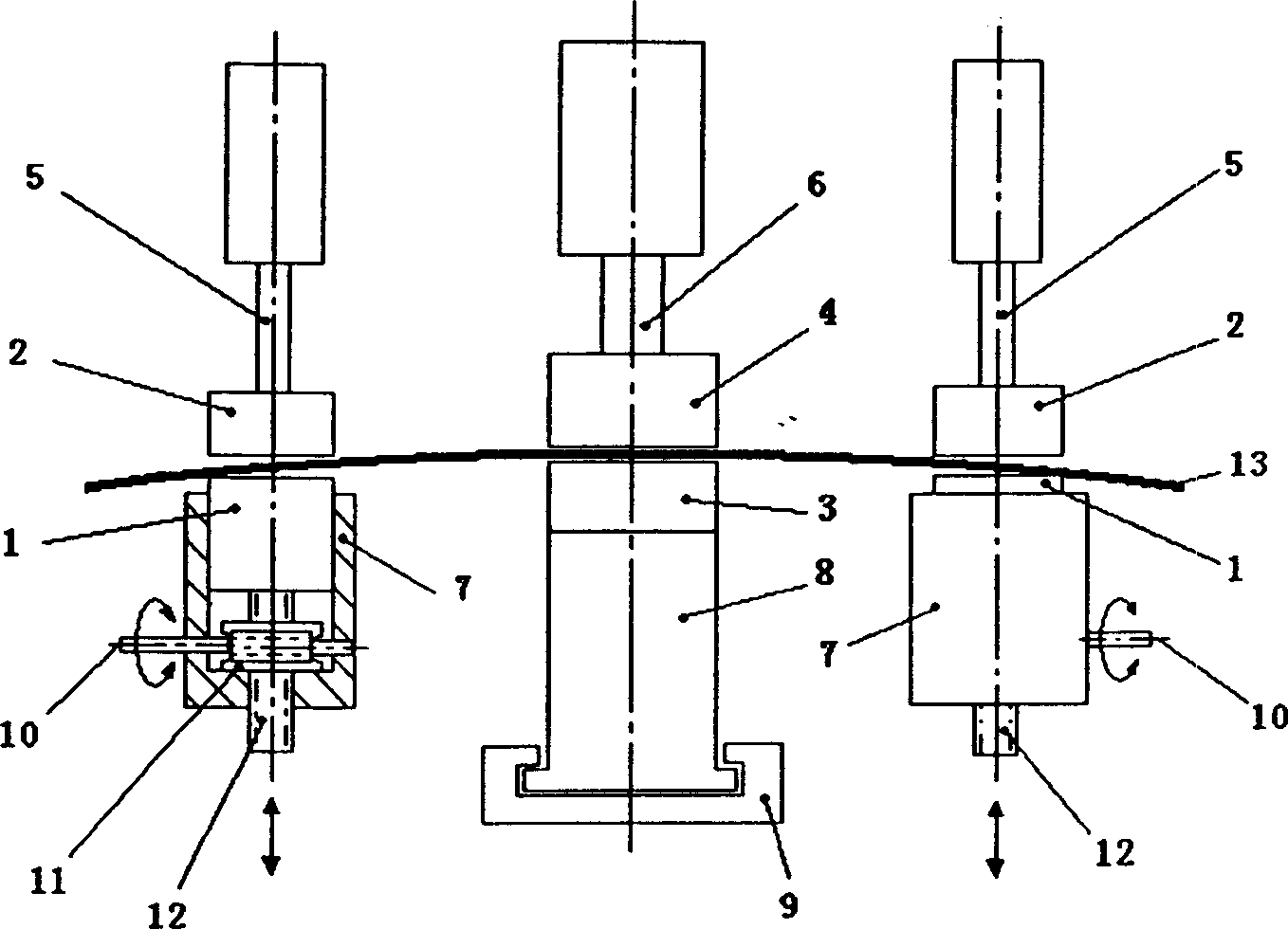

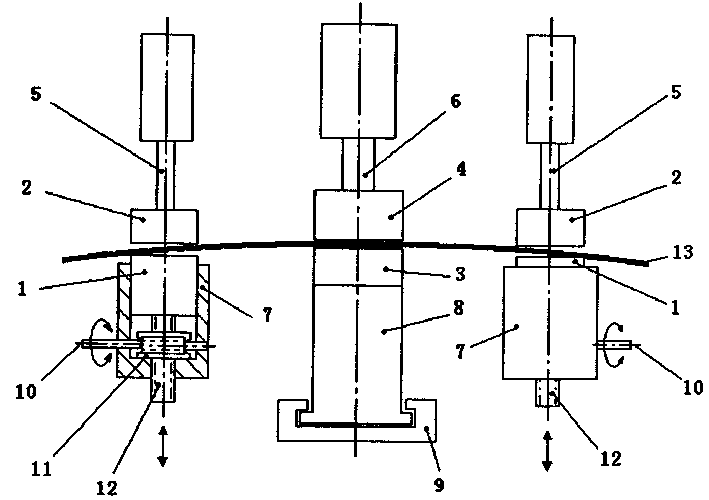

[0012] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0013] figure 1 The vertical pre-bending device of the rib cold bending machine shown includes the side lower chuck 1 installed on the side frame 7 of the cold bender, the side upper chuck 2 driven by the side clamping cylinder 5, and the middle frame 8 The middle and lower chuck 3, the middle and upper chuck 4 driven by the middle clamping cylinder 6, and the worm 10, worm wheel 11, and side lower chuck support screw 12 that can drive the side lower chuck 1 to move up and down, as for the worm 10 can utilize hand wheel, electric motor or hydraulic motor etc. to drive and rotate.

[0014] The vertical pre-bending device of this rib cold bending machine: the worm 10 on the side frame 7 is driven to rotate by means of a hand wheel, an electric motor or a hydraulic motor, and the worm 10 drives the worm wheel 11 to rotate, and the worm wheel 11 and the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com