Ship with watertight wall

A ship, watertight technology, applied in the structural field of bulkheads, can solve problems such as difficulty in meeting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

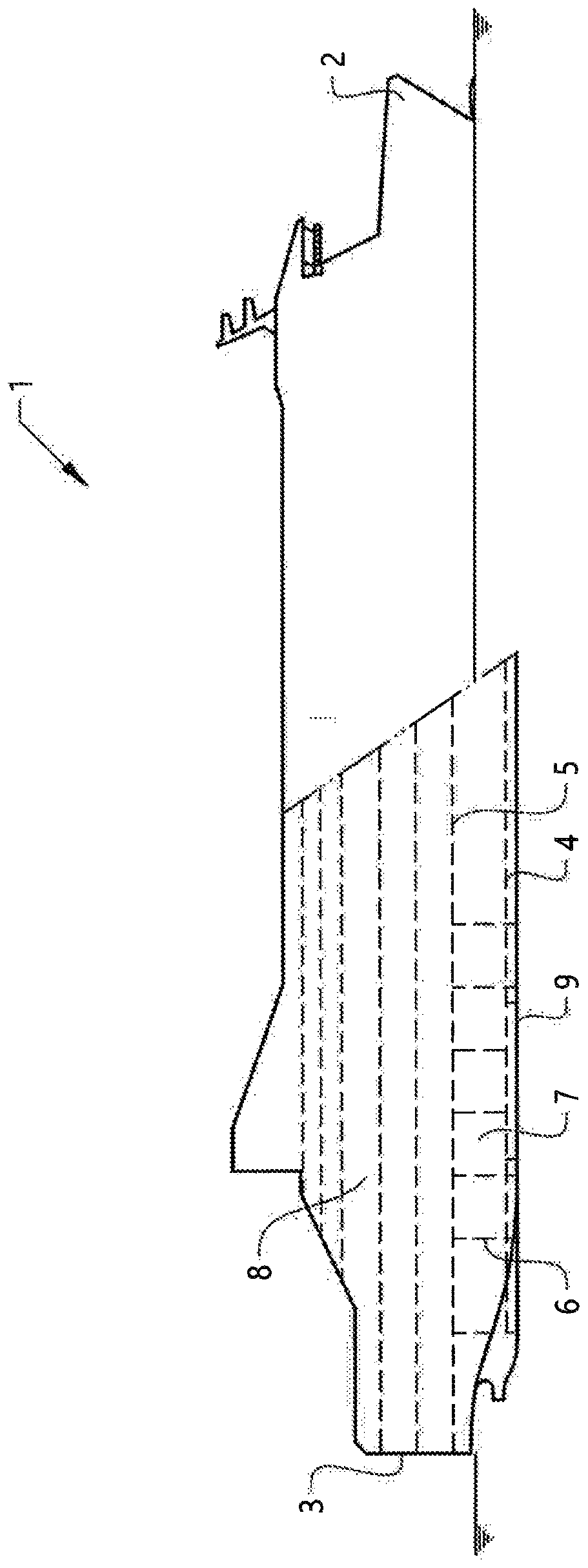

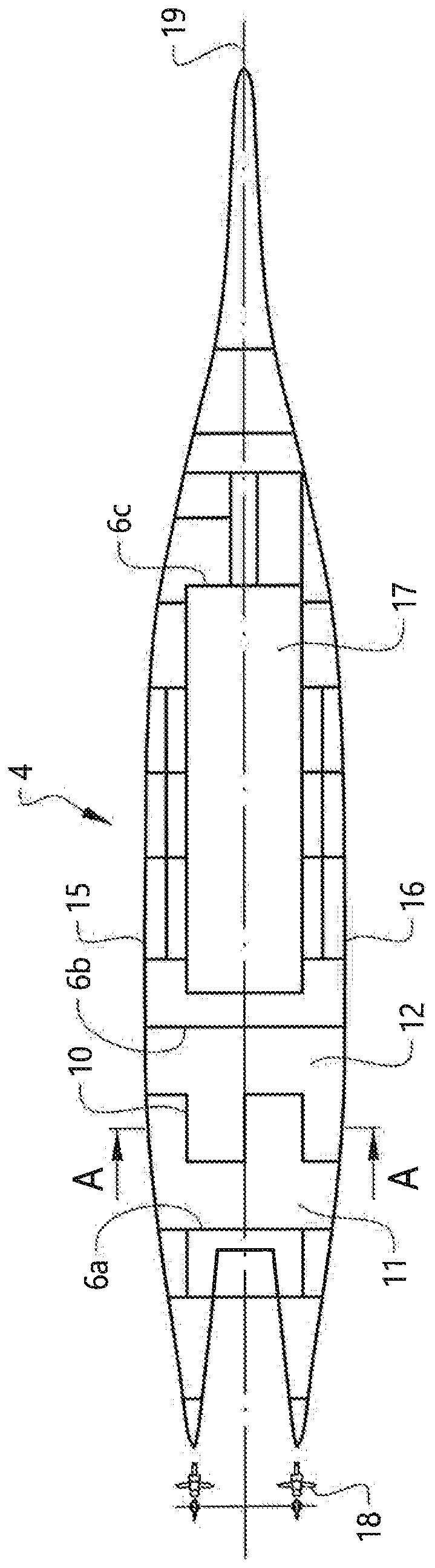

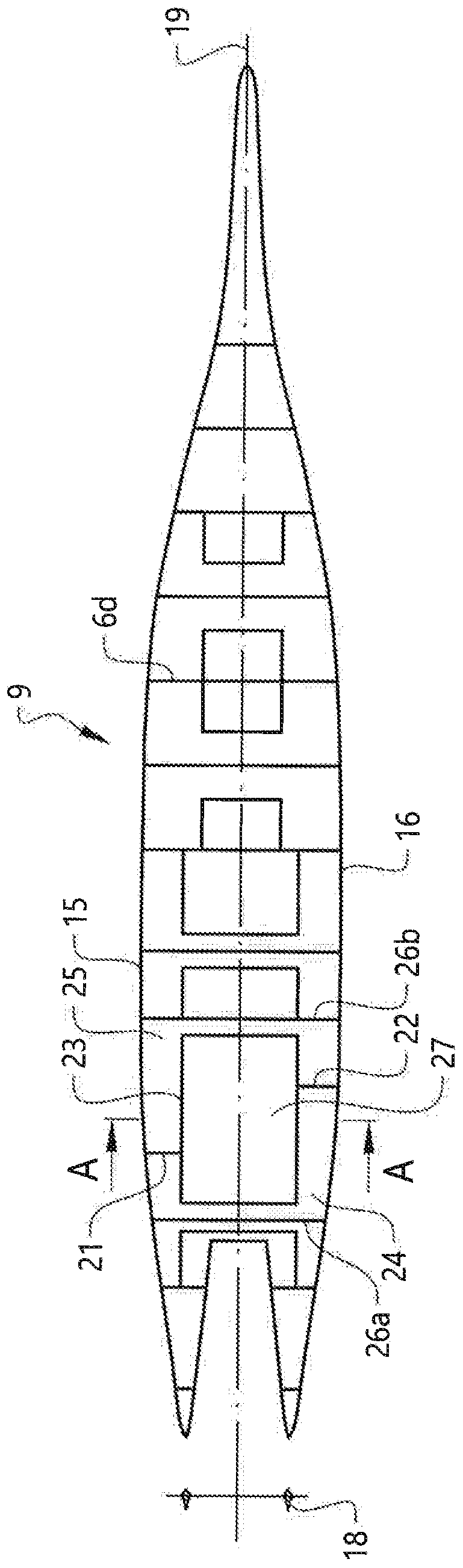

[0064] figure 1 is a schematic partial cutaway side view showing an embodiment of a vessel 1 according to the invention. Vessel 1 is a roll-on / roll-off (RO-RO) passenger ship and has a bow / bow 2 and a stern 3 . The term "longitudinal direction" refers to the longitudinal axis of the vessel 1 extending between the bow 2 and the stern 3 . The term "transverse direction" refers to the width of the vessel 1 (perpendicular to figure 1 direction of the plane).

[0065] The ship 1 has a lower deck (tank roof) 4 and an upper deck (bulkhead deck) 5 arranged above the tank roof 4 . These decks 4, 5 mainly extend in the longitudinal direction of the vessel 1, but also in the transverse direction.

[0066] The tank top 4 is provided with a watertight wall (bulkhead) 6 extending vertically between the lower deck 4 and the upper deck 5 and defining a plurality of divided watertight compartments 7 distributed between the upper deck 5 and the lower deck 4 .

[0067] The floor / keel 9 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com