Sheet cage used for rolling bearing

A technology of rolling bearings and cages, used in bearing elements, shafts and bearings, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

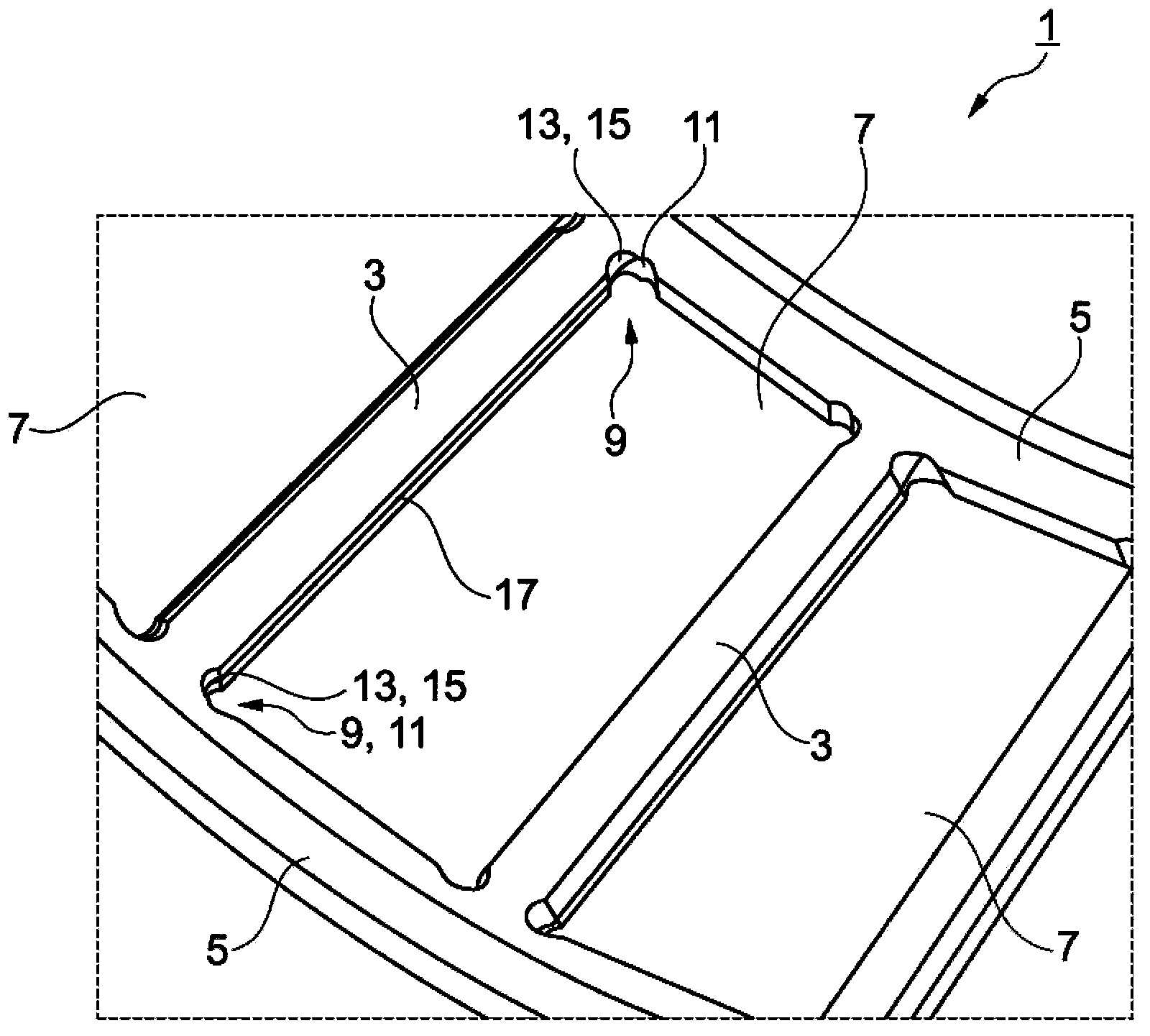

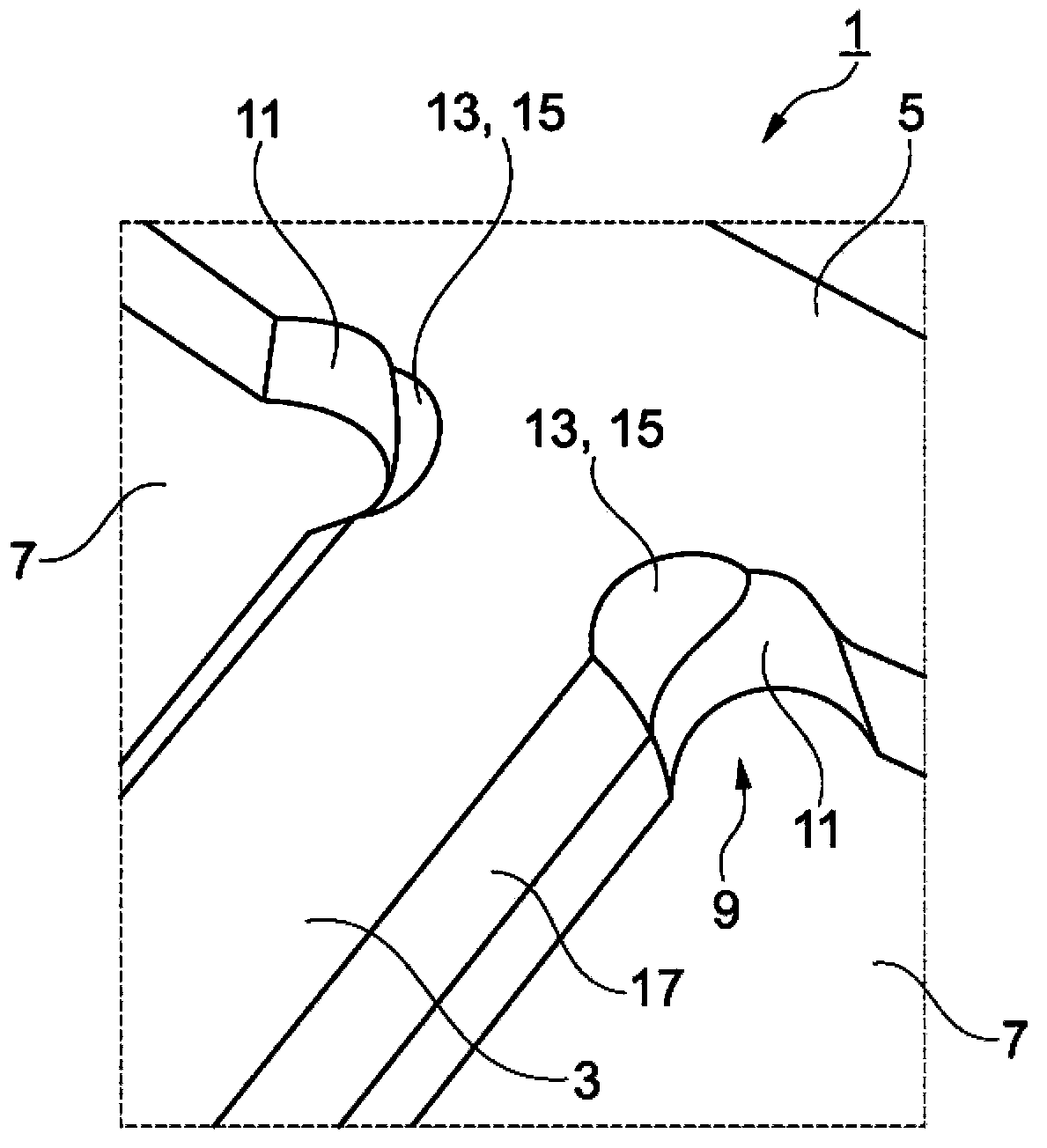

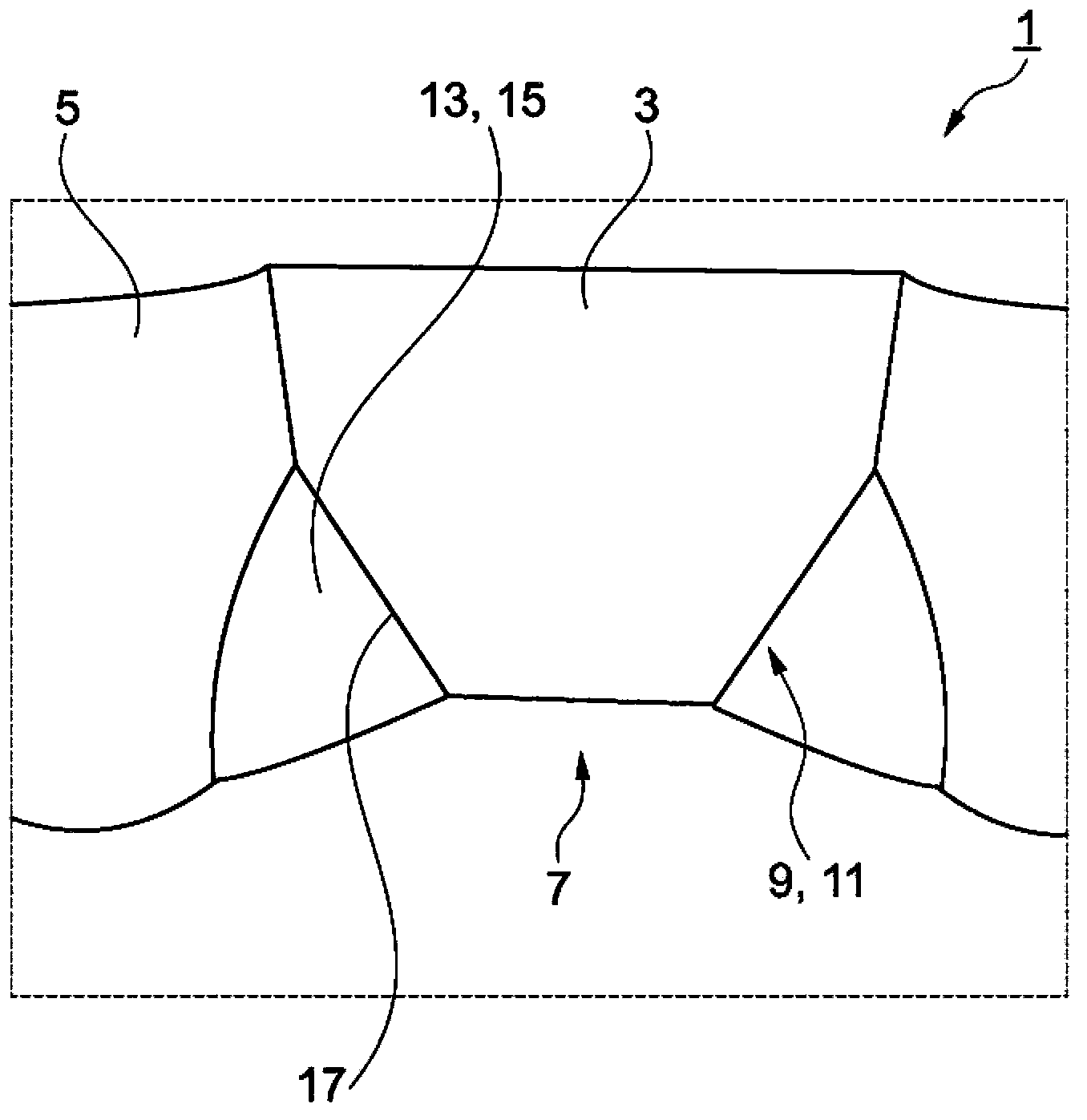

[0030] figure 1 A section of a cage 1 for roller-shaped rolling elements is shown in a three-dimensional view. Cage 1 is produced from sheet metal and consists of a number of webs 3 extending axially between two rings 5 . Angled cage pockets 7 are formed in each case between two adjacent webs 3 and serve to accommodate the rolling bodies. rolling body in Figure 4 shown in .

[0031] Recesses 11 are in each case embossed into the corners 9 of the cage pockets 7 . The recess 11 serves for the rounding of the corner 9 . The recess 11 is widened inwardly in the radial direction by the bevel 13 . In this case, the bevel 13 is punched into the recess 11 starting from the inner periphery of the cage 1 . By stamping, the material of the cage 1 is plastically deformed in a targeted manner at the corners 9 of the cage pockets 7 , so that it is dense and does not have to be removed. The chamfer 13 can correspond accordingly to the installed rolling bodies.

[0032] All in all,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com