Welding structure for hole pattern of aggregate penetration hole in ship bulkhead plate and supplementary plate

A technology of welding structure and bulkhead plate, applied in the direction of hull bulkhead, hull, ship parts, etc., can solve the problems of high process precision, poor commonality of openings, no universality, etc., to achieve wide applicability and reduce stress. Concentration factor, the effect of prolonging the fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

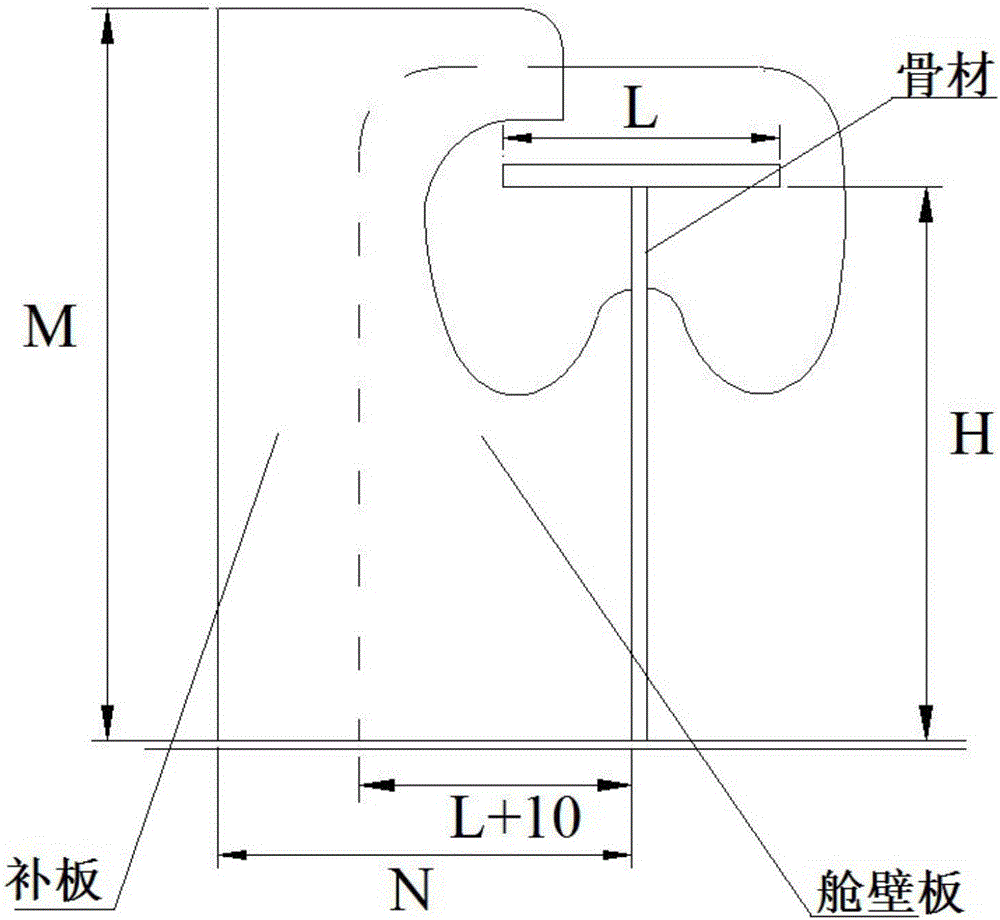

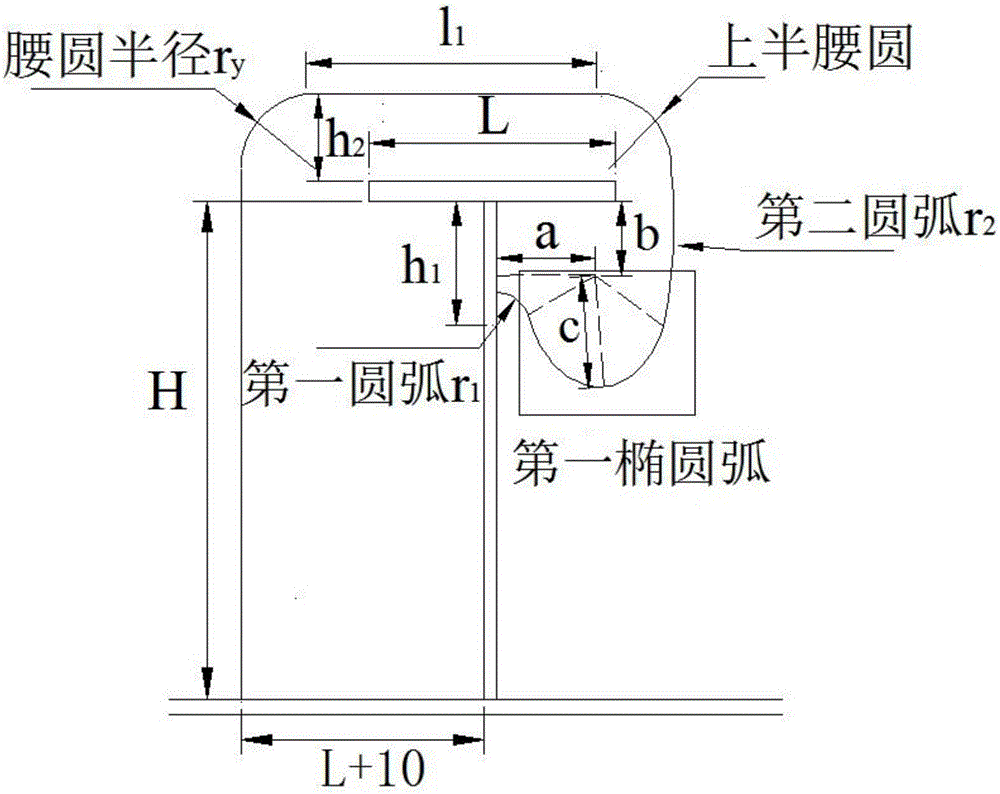

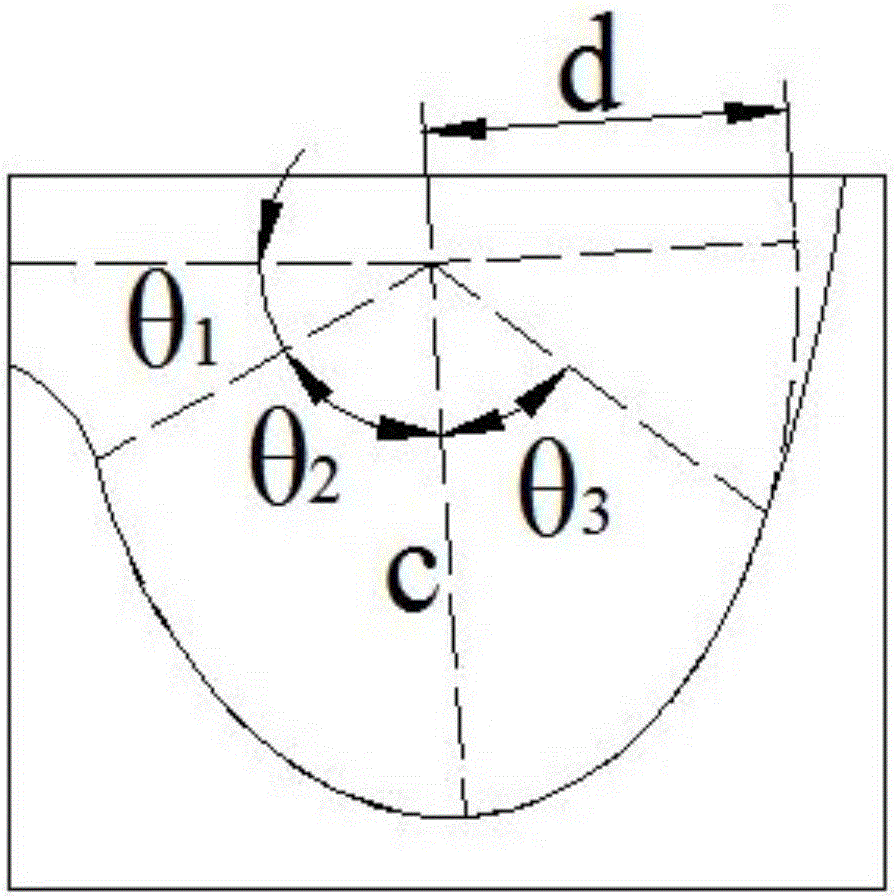

[0023] The present invention relates to a ship bulkhead plate skeleton opening and its matching patch welding structure, including the through-hole pattern of the ship's frame and its matching patch structure. Such as figure 2 , image 3 As shown, the through hole includes a first circular arc, the first circular arc is connected to the first elliptical arc, the first elliptical arc is connected to the second circular arc, the upper end of the second circular arc is connected to the upper half of the waist circle, and the lower left of the upper half of the waist circle Connect straight lines. Such as Figure 4 , Figure 5 As shown, the supplementary board includes a third circular arc, the lower end of the third circular arc is connected to the second elliptical arc, the second elliptical arc is connected to the fourth circular arc, the other end of the fourth ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com