Plasma-MAG hybrid welding method

A plasma welding and composite welding technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of prolonged production cycle, incomplete weld penetration, large welding deformation, etc., to improve welding quality and meet basic needs , The effect of reducing welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

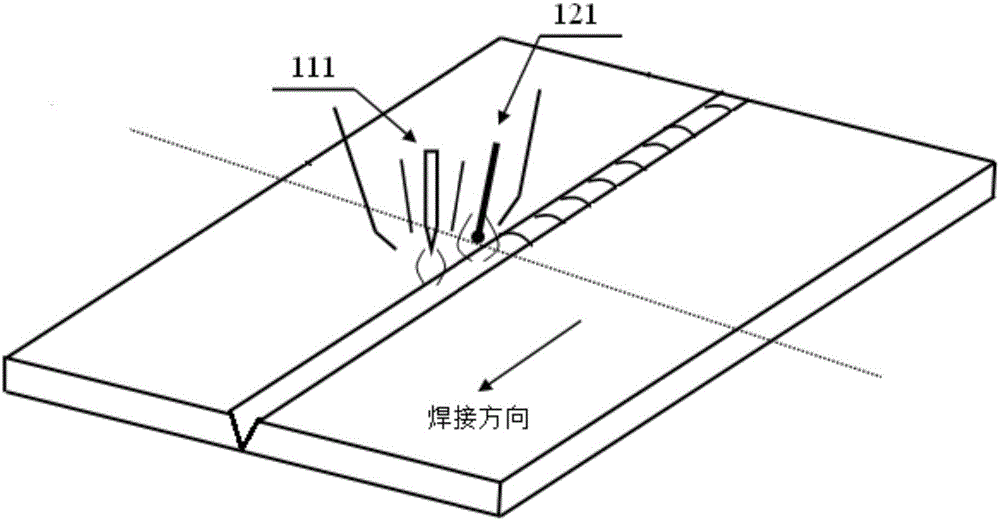

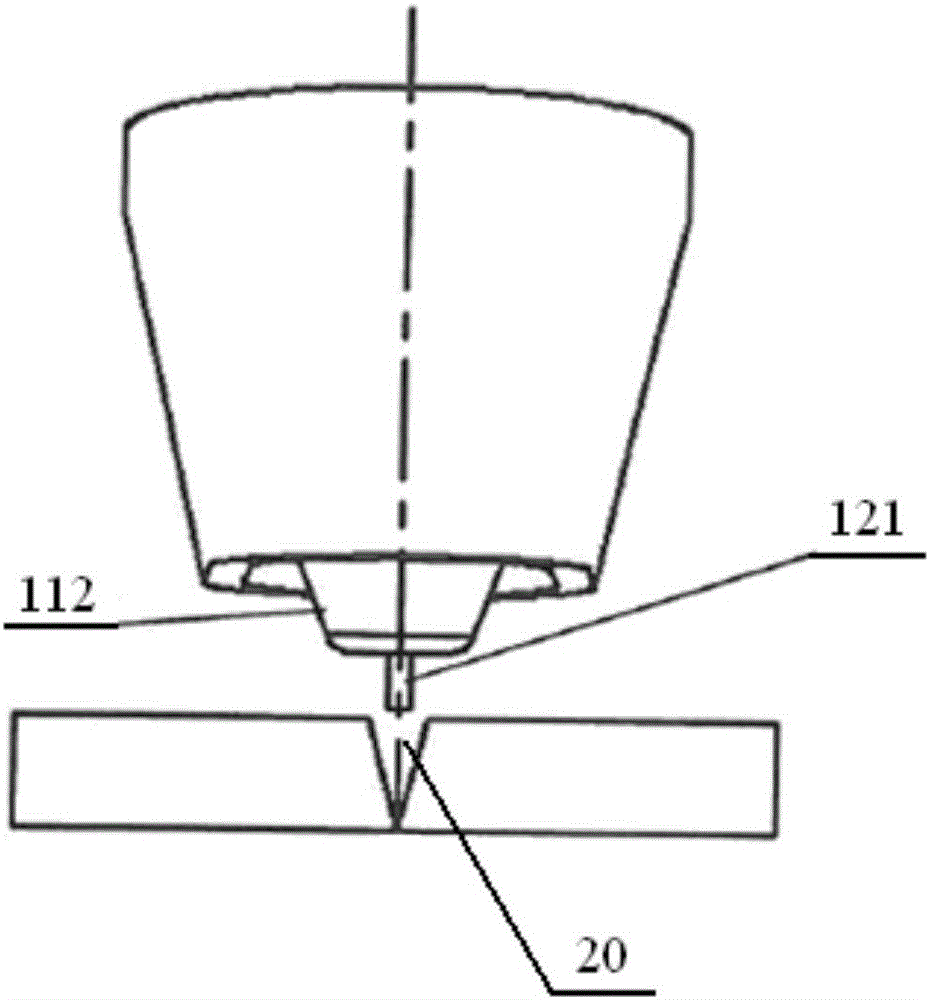

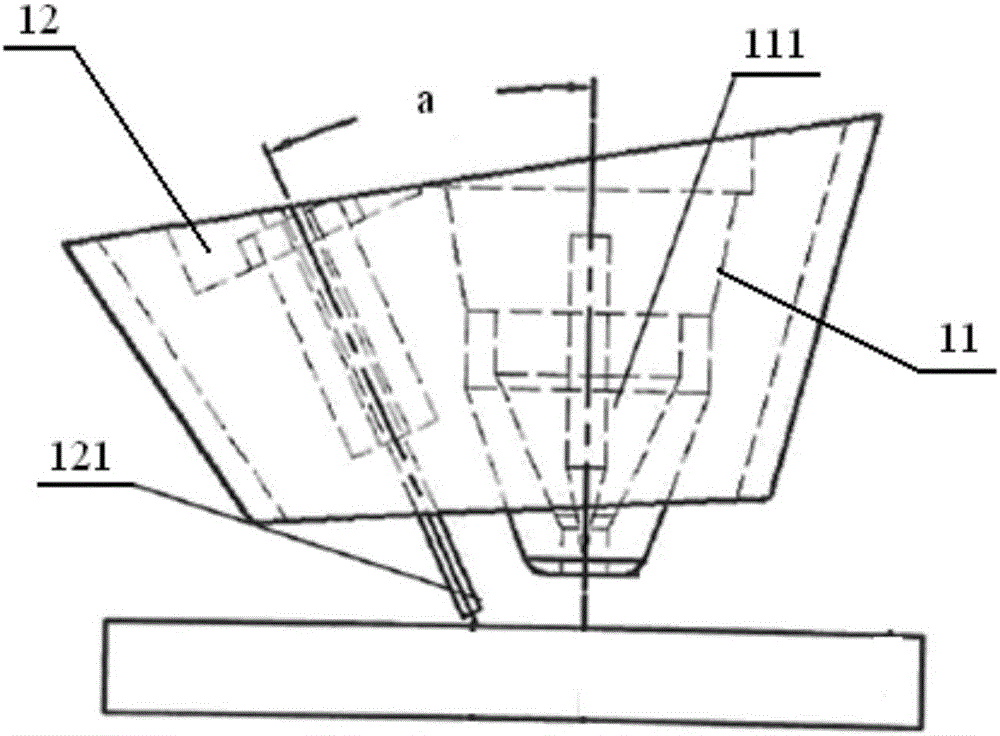

[0028] In the plasma-MAG composite welding method provided by the present invention, during welding, the plasma tungsten electrode is placed in front, and the MAG welding wire is placed behind, wherein a preset distance is maintained between the tip of the tungsten electrode and the tip of the welding wire, and the distance between the two tips of the welding piece The height of the surface is consistent; moreover, the tungsten electrode is arranged perpendicular to the welding bead, and the welding wire and the tungsten electrode form a preset angle.

[0029] As mentioned above, this hybrid welding method utilizes the characteristics of high energy density of plasma beam and strong welding penetration ability, through the keyhole ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com