Turbine Rotor Blade

一种叶轮机动翼、轮毂的技术,应用在动翼领域,能够解决强度和耐久性存在问题等问题,达到惯性力矩抑制、抑制应力集中、减小应力集中系的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

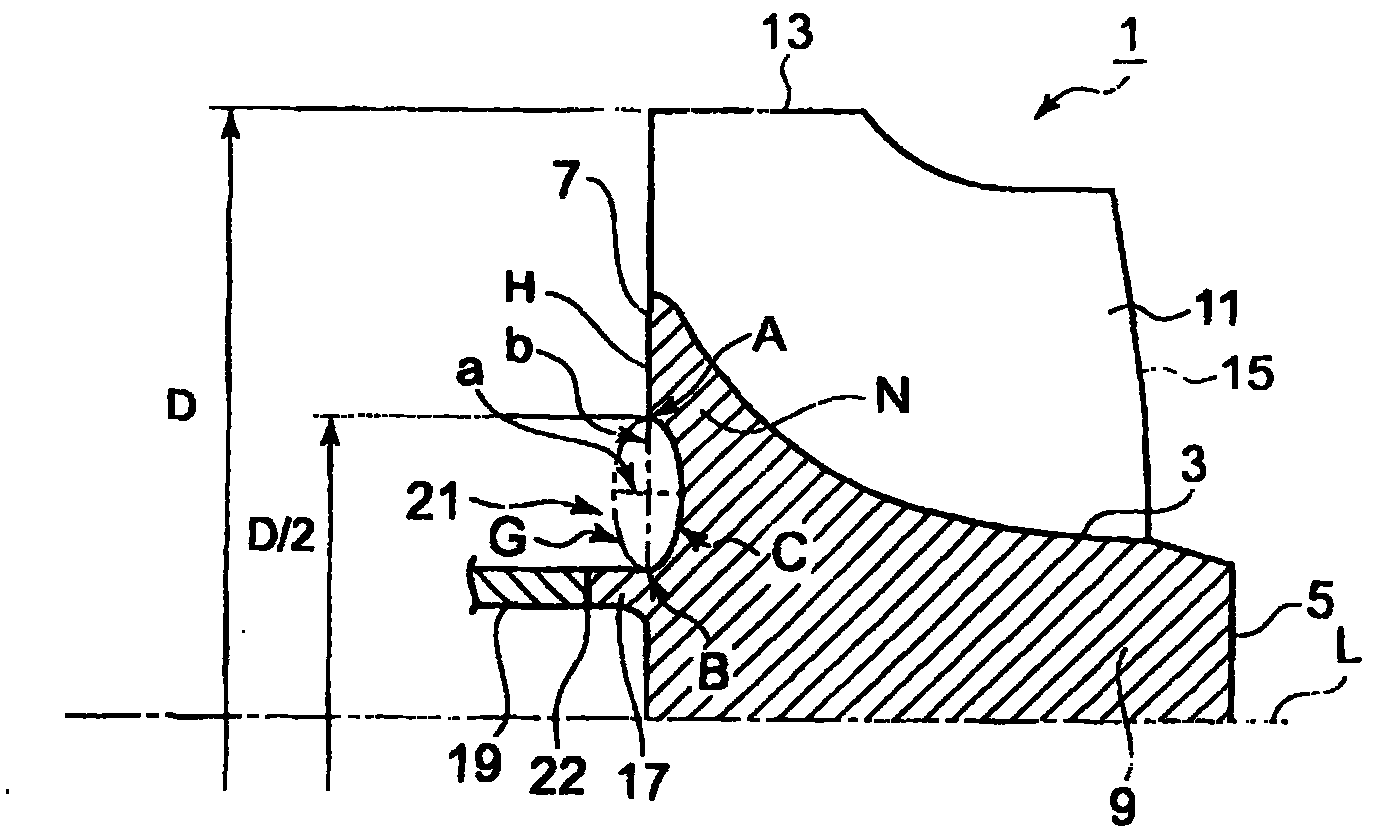

[0045] An example of an impeller motor wing for a turbocharger for a vehicle or a ship will be described. figure 1 Axial cross-sectional view of the impeller blade 1 is shown. In the impeller blade (hereinafter referred to as the blade) 1, a hub portion 9 formed in a shaft shape and having an outer peripheral side surface 3, a front end surface 5, a rear end surface (back surface) 7 and A plurality of wing portions 11 are integrally formed on the outer peripheral side surface 3 of the hub portion 9 by injection molding, casting, sintering, or the like.

[0046] The outer peripheral side surface 3 is curved so as to gradually increase in diameter from the front end surface 5 toward the rear surface 7 of the hub portion 9 , and a plurality of wing portions 11 are vertically provided on the curved surface along the axial direction.

[0047] Moreover, the leading edge 13 of the wing portion 11 is arranged on the outer peripheral side in the radial direction, and the trailing edge...

no. 2 approach

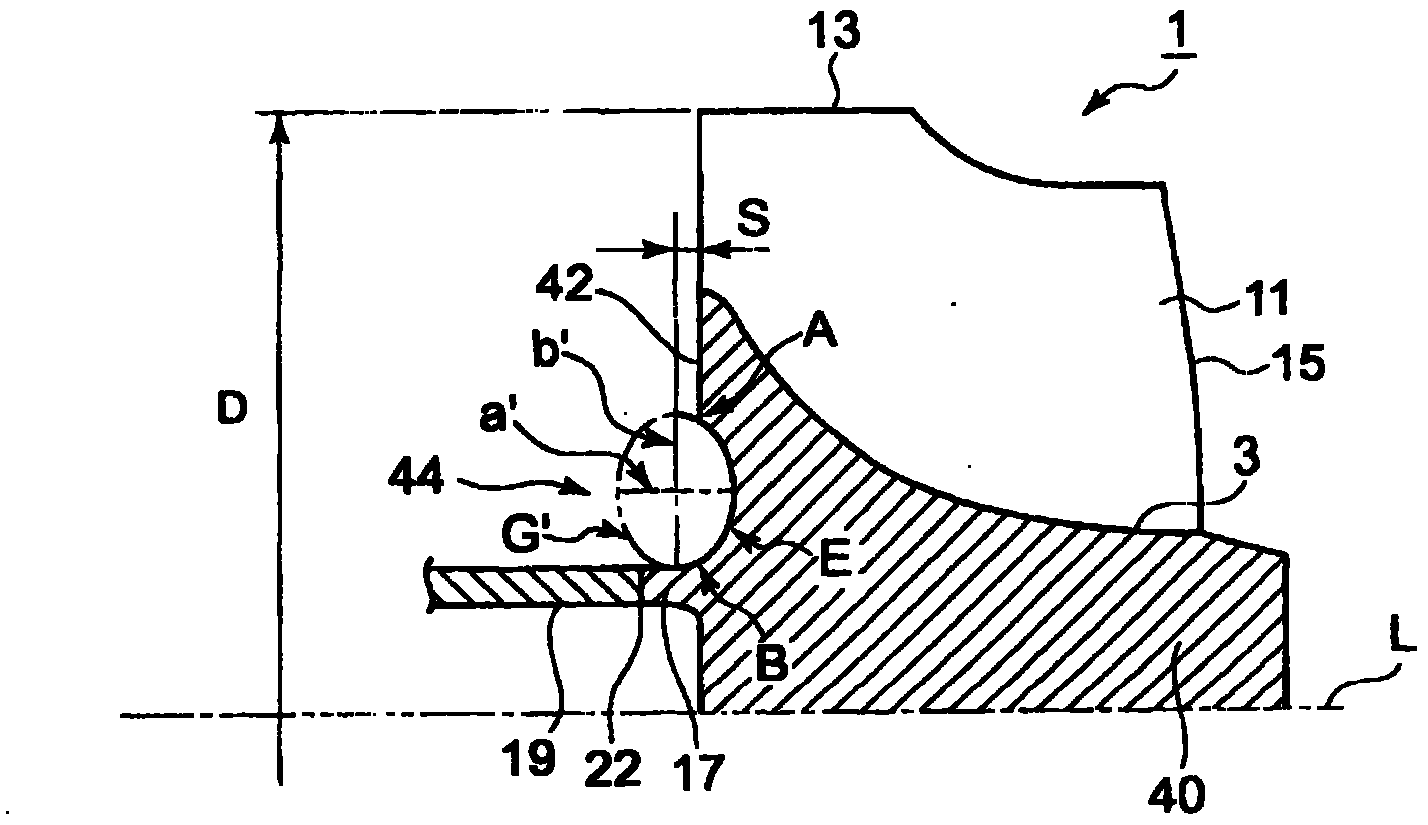

[0068] Next, refer to figure 2 A second embodiment will be described. In addition, the same code|symbol is attached|subjected to the same part as the structural member demonstrated in 1st Embodiment, and description is abbreviate|omitted.

[0069] Such as figure 2 As shown, on the back surface 42 of the hub portion 40, the cross-sectional shape of the annular concave portion 44 formed centering on the center line L of the rotating shaft 19 in the direction of the rotating shaft is composed of an ellipse G′, and the short diameter a′ The long arc E of the ellipse formed with the long diameter b' is formed. The major diameter b of the long arc E of this ellipse does not coincide with the back surface 42 . The major diameter b' is located at a position shifted by a distance s from the surface position of the back surface 42 toward the outer side of the hub portion 40, and is formed by a part of an elliptical long arc shape. That is, the curved shape forming the concave port...

no. 3 approach

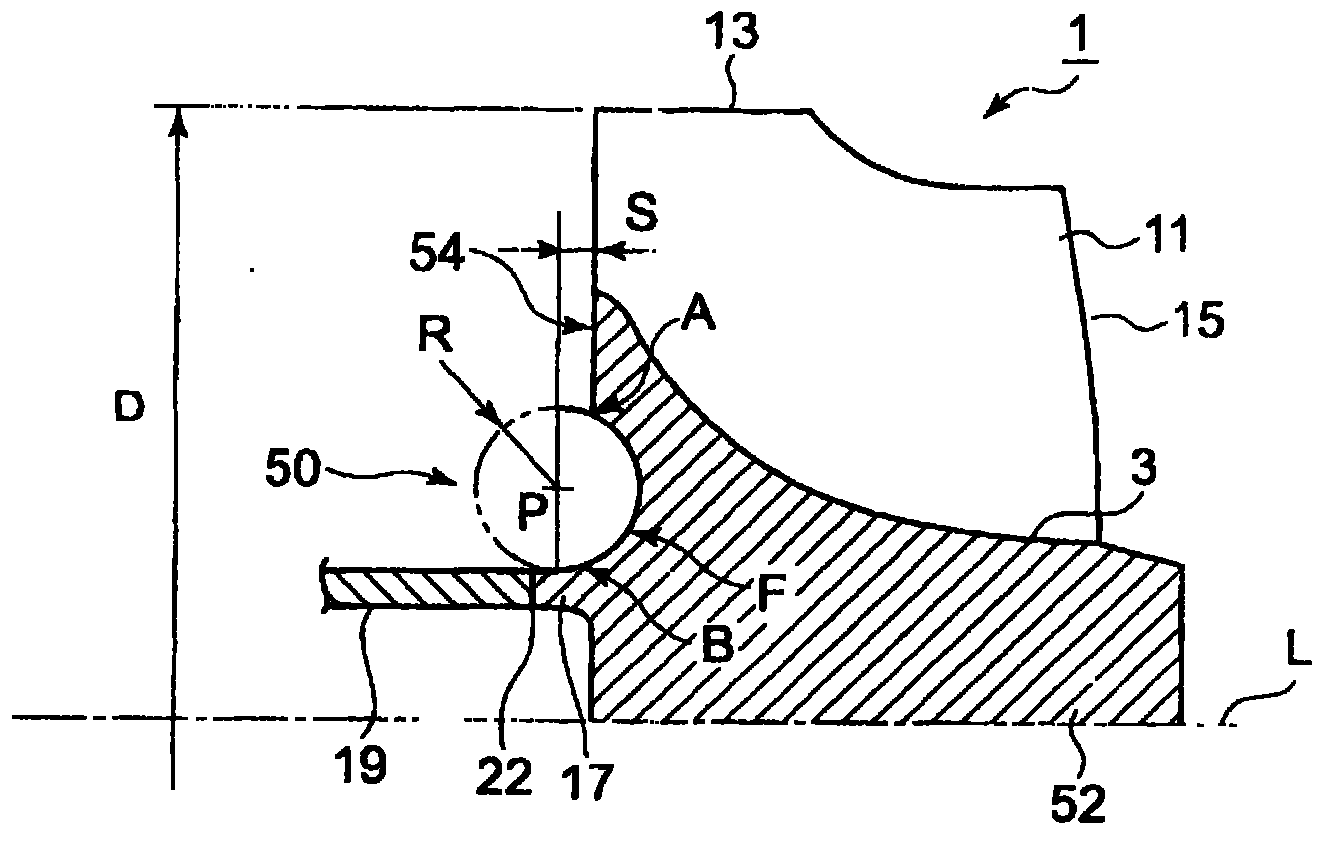

[0075] Next, refer to image 3 A third embodiment will be described. In addition, the same code|symbol is attached|subjected to the same member as the structural member demonstrated in 1st Embodiment and 2nd Embodiment, and description is abbreviate|omitted.

[0076] Compared with the ellipse of the second embodiment, the third embodiment forms the shape of the concave portion 50 by a circular arc.

[0077] Such as image 3As shown, on the back surface 54 of the hub portion 52 of the rotor blade 1, the cross-sectional shape of the annular concave portion 50 formed centering on the center line L of the rotating shaft 19 in the direction of the rotating shaft is constituted by an arc shape with a radius R. , formed by an arc F of a portion of the circumference. The center P of the arc F is located at a position displaced by a distance s from the surface position of the back surface 54 to the outside of the hub portion 52 as in the second embodiment. That is, the curved shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com