Aggregate through hole pattern structure of ship cabin wall plate

A technology of bulkhead plate and hole pattern, which is applied in the direction of hull bulkhead, hull, and hull parts, etc. It can solve the problems of high stress concentration points and high stress, reduce stress concentration points, improve fatigue strength and long fatigue life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

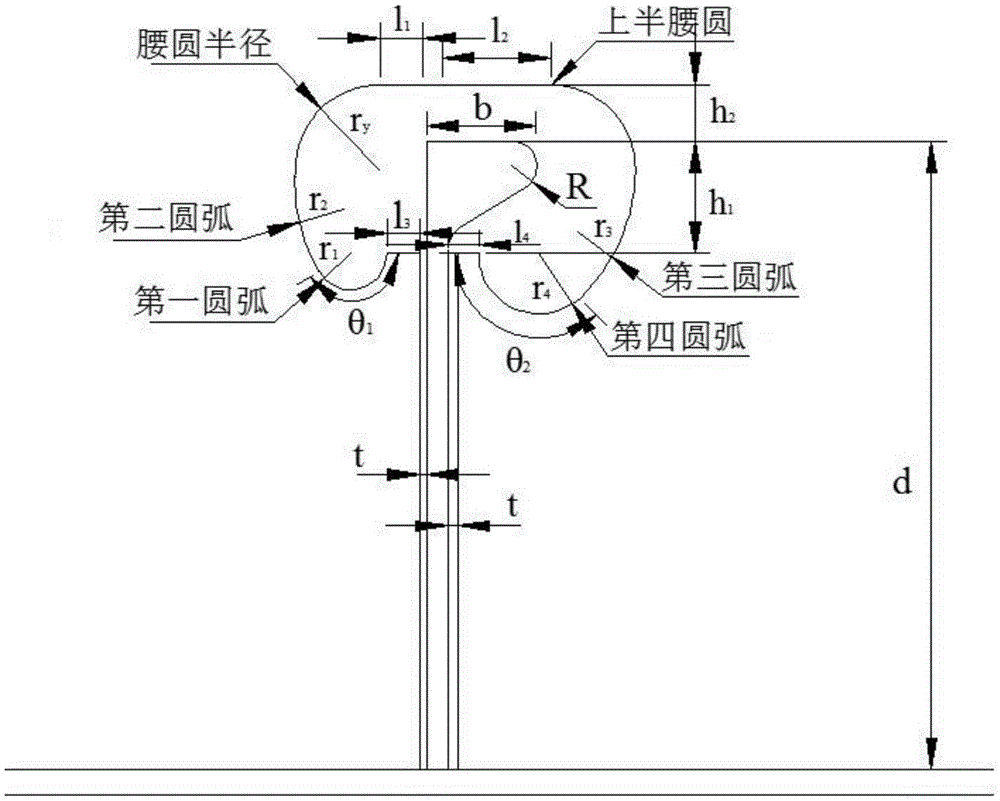

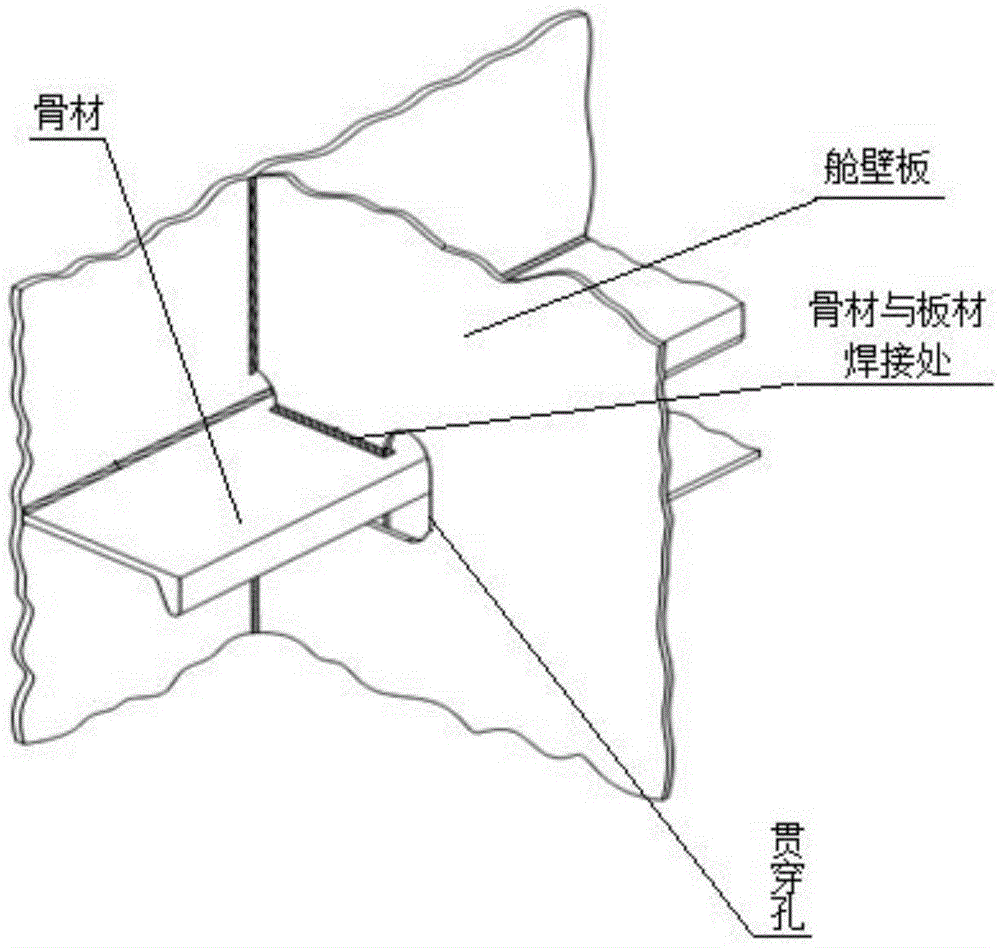

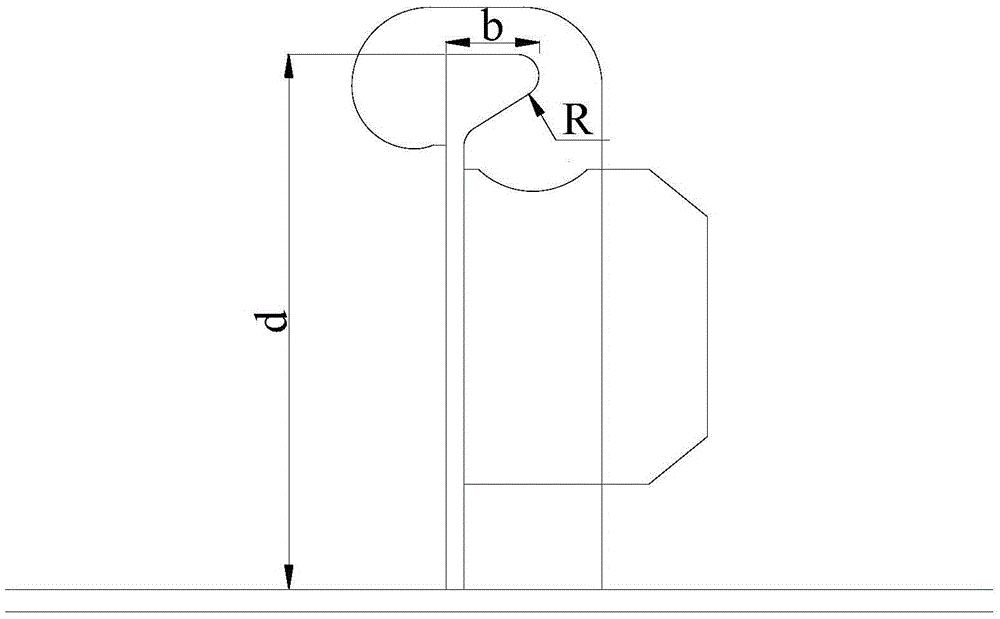

[0020] like Figure 1 to Figure 3 As shown in the figure, a through-hole structure of a ship bulkhead plate includes horizontal straight lines on both sides of the opening of the through-hole, the end of the straight line on the left side is connected to the first arc, and the upper end of the first arc is connected to the second arc. Two arcs, the upper end of the second arc is connected to the upper half of the waist, the lower right end of the upper half of the waist is connected to the third arc, the lower end of the third arc is connected to the fourth arc, and the other end of the fourth arc is connected to the through The straight line connection on the right side of the hole opening, the through hole is an asymmetric hole. The length l of the horizontal line on the left side of the through-hole opening 3 The length l of the horizontal line to the left 4 equa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com