Barrel defect welding repair method

A welding repair and cylinder technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems of inability to ensure the welding quality of the back side, the inner wall cannot be welded, and the repair is difficult, so as to improve the one-time repair pass rate, The effect of avoiding repeated cracking and reducing welding shrinkage stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

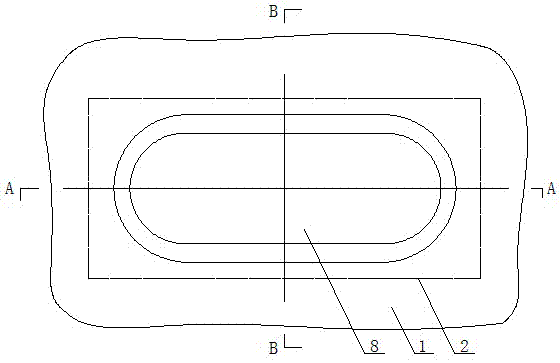

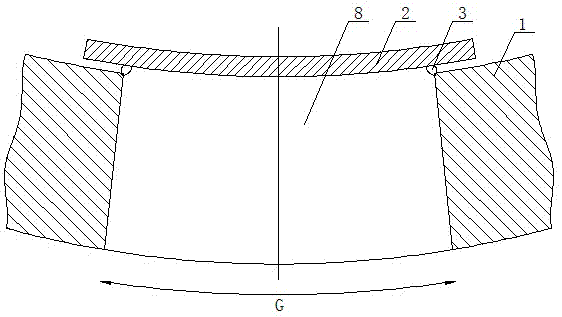

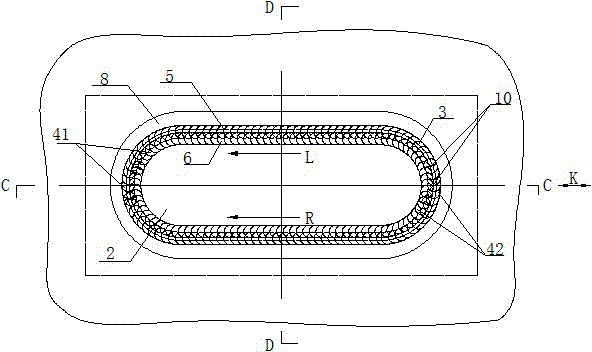

[0029] Such as Figure 1 to Figure 7 As shown, in a boiler high-temperature reheater header of a certain project, defects exceeding the standard were found in the circular seam inspection of cylinder 1. The original same product had similar defects. Repair welding was carried out according to conventional methods, and the success rate of one-time repair was only 30%. And every defect often needs to be repaired and welded repeatedly 2 to 3 times before it can succeed, which is time-consuming and labor-intensive. Adopt cylinder defect welding repair method of the present invention, repair, its main procedure is as follows:

[0030] 1) Ultrasonic inspection accurately locates and marks the length, width and depth of the defect area;

[0031]2) Use machining to remove defects, form through holes 10, and conduct 100% MT or PT flaw detection to ensure that defects are removed;

[0032] 3) The bevel 8 of the defect area is machined, and the inner side of the through hole of the cyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com