Quick overall foaming device and method for vehicle-mounted tank

A foaming device and tank technology, which is applied in the field of liquid tank trucks and fire trucks, can solve the problems that the overall quality of foaming is difficult to control, affects the insulation effect, and the density of foamed polyurethane insulation layer and the foaming hollow rate are unstable. Achieve the effect of reducing the risk of stripping, reducing production costs, and facilitating and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to further understand the content of the present invention, the composition and working process of the present invention will be described in detail in conjunction with the accompanying drawings.

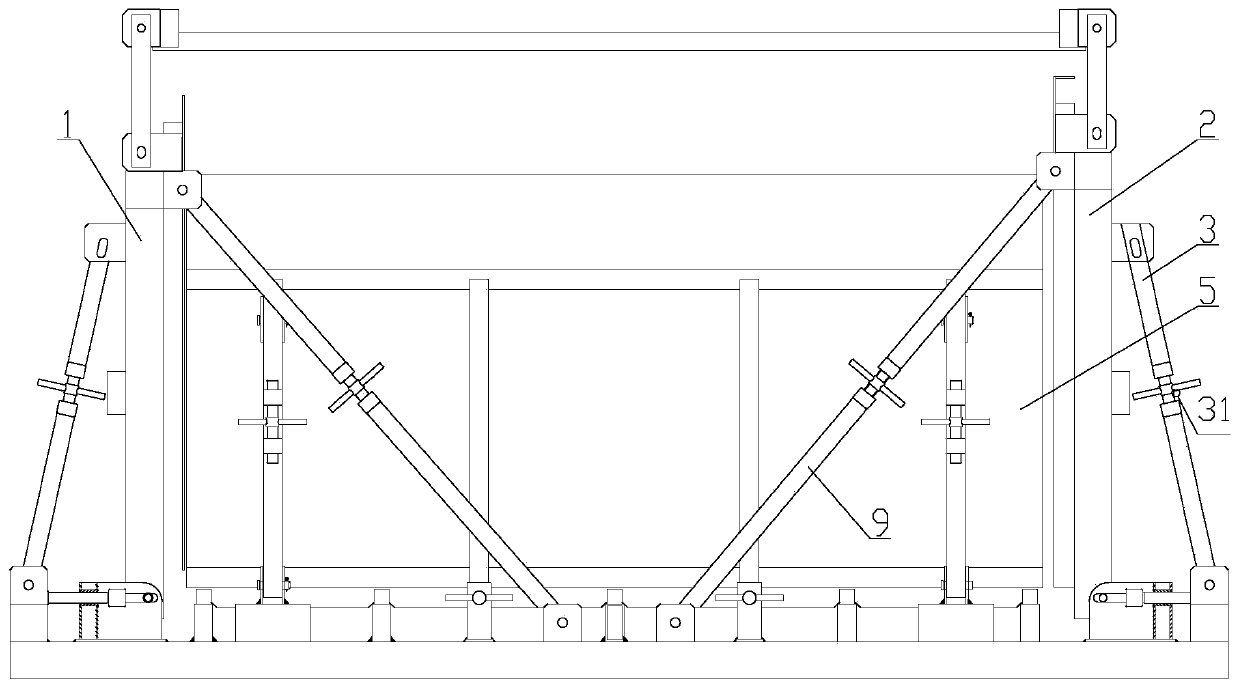

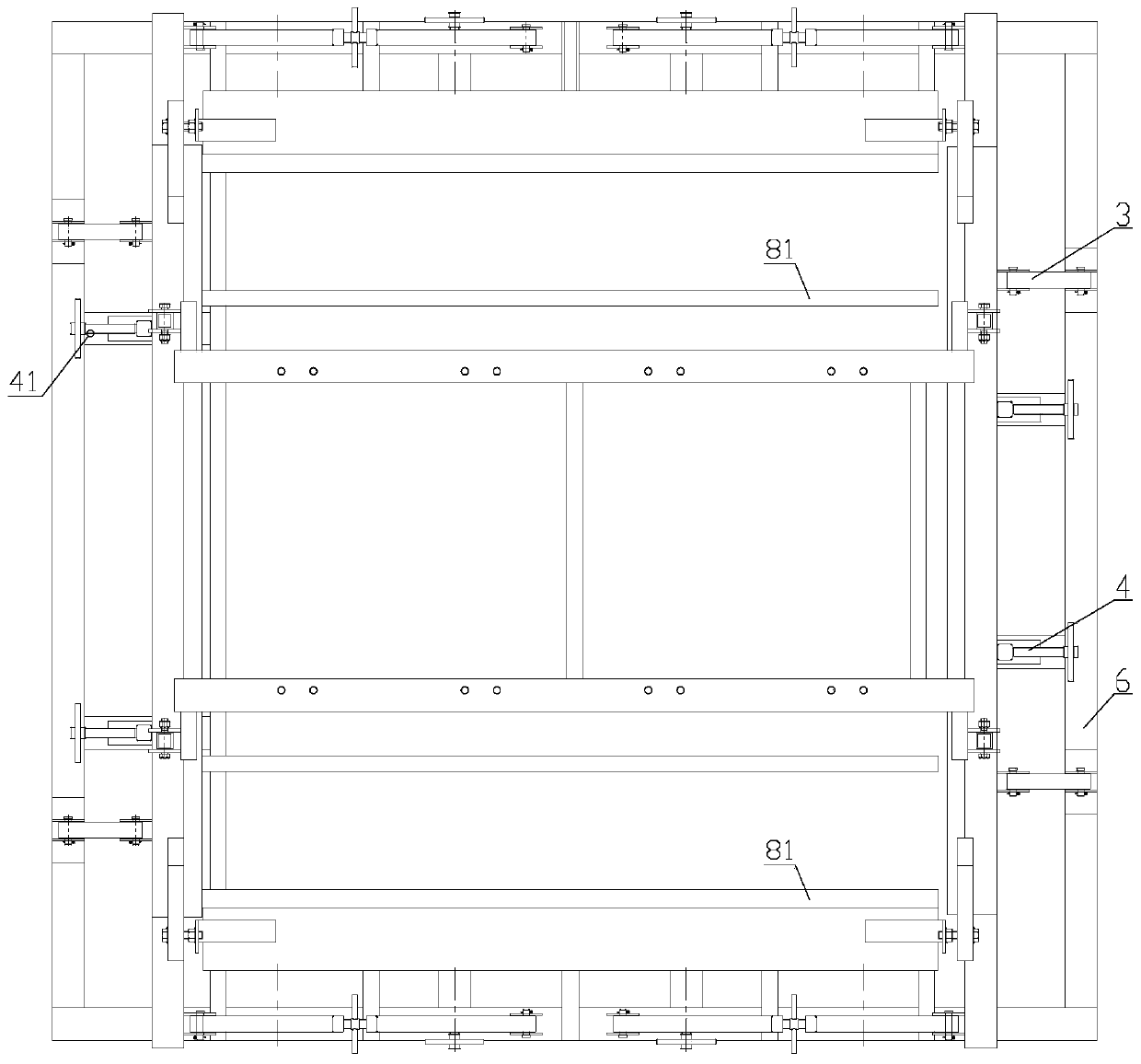

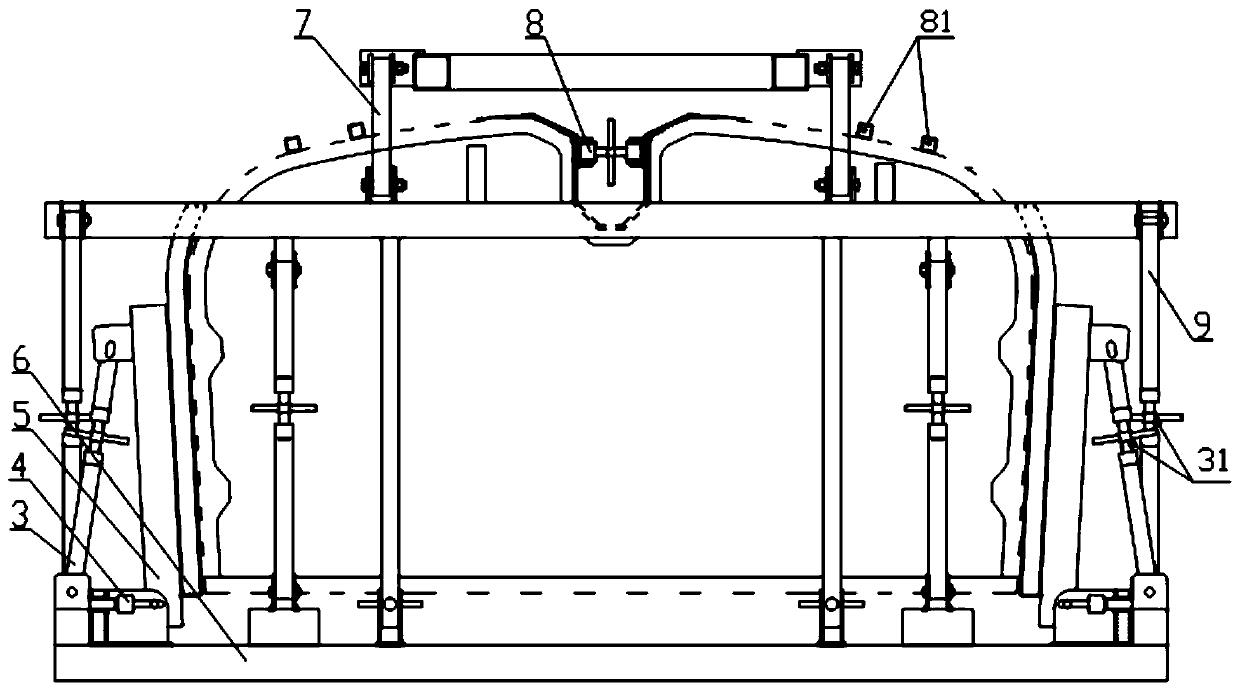

[0040] like Figure 1-Figure 3 As shown, the rapid overall foaming device for the tank body includes a front formwork 1, a rear formwork 2, a side formwork 5, a bottom frame 6, a support adjustment device 3, a push-pull adjustment device 4, a tank bottom beam connection frame 7, and a pull rod device 9. Bottom foaming tooling 8, front and rear mold bases and left and right side mold bases are installed on the base frame 6, eight push-pull adjustment devices 4 are connected to the four sides of the base frame, and one end of the eight support adjustment devices is connected to the base frame 6, The other end is connected with the front and rear formworks and the left and right side formworks respectively; the tie bar device 9 is two groups of four sets located at both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com