Display panel and manufacturing method thereof and display device

A technology for a display panel and a manufacturing method, which is applied in the directions of semiconductor devices, electrical components, circuits, etc., can solve the problems of easy peeling of the touch barrier layer and the flat layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

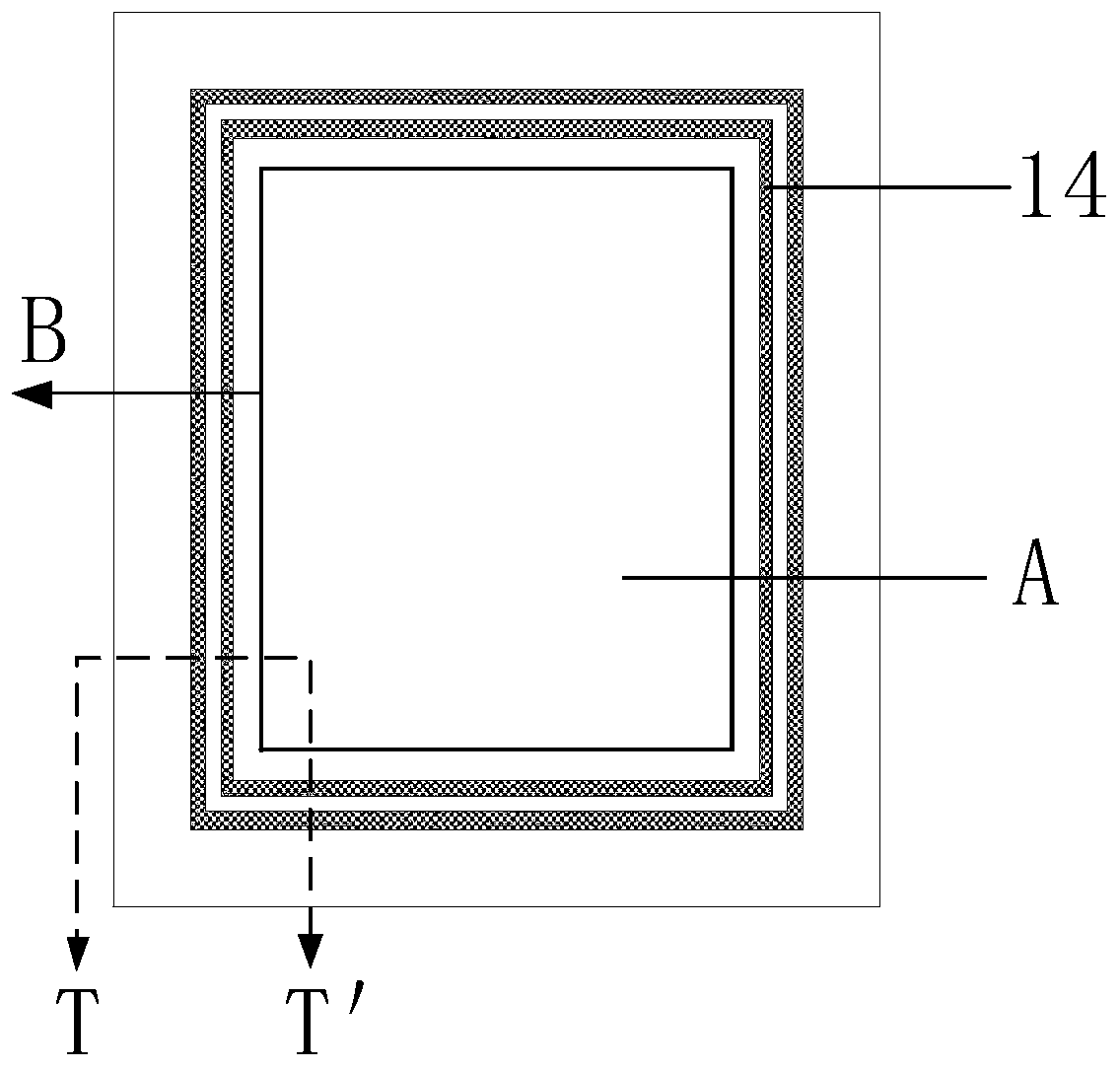

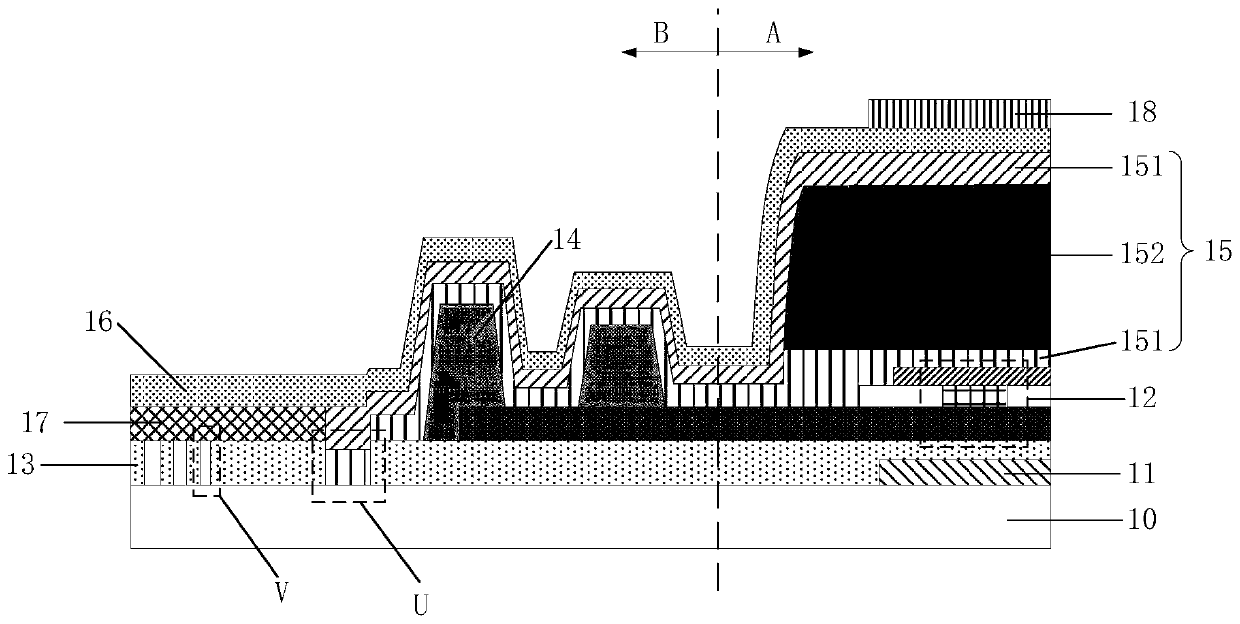

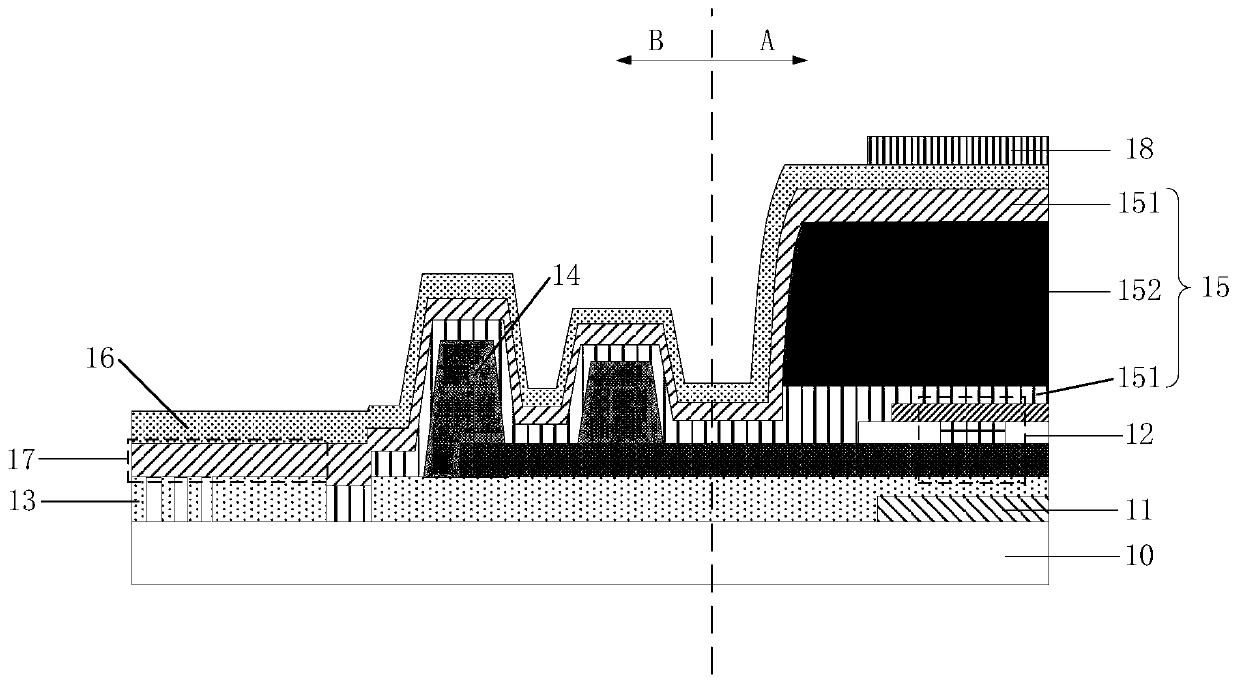

[0053] In the actual process, before forming the touch electrode layer, it is necessary to form a layer of touch barrier layer on the encapsulation layer. After forming the encapsulation layer, the edge area of the OLED display A wet cleaning process will be performed before the control barrier layer. During this process, the exposed flat layer will absorb moisture. After the touch barrier layer is formed, when the high temperature process is performed, the moisture in the flat layer will be blocked by the touch barrier layer. , and cannot be discharged, resulting in peeling between the touch barrier layer and the flat layer, and even the OLED display panel is scrapped due to the damage of the film layer.

[0054] Based on this, in order to solve the problem of easy peeling between the touch barrier layer and the flat layer in the related art, the embodiments of the present invention provide a display panel, a manufacturing method thereof, and a display device.

[0055] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com