Construction method of large-gap thin overlay

A technology of thin-layer overlay and construction method, which is applied to cohesive pavement paved on site, roads, roads, etc., can solve the problems of large void ratio, poor road cohesion, and rapid temperature loss of ultra-thin overlays with large voids. Achieve the effects of saving maintenance costs, improving anti-skid performance, and reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

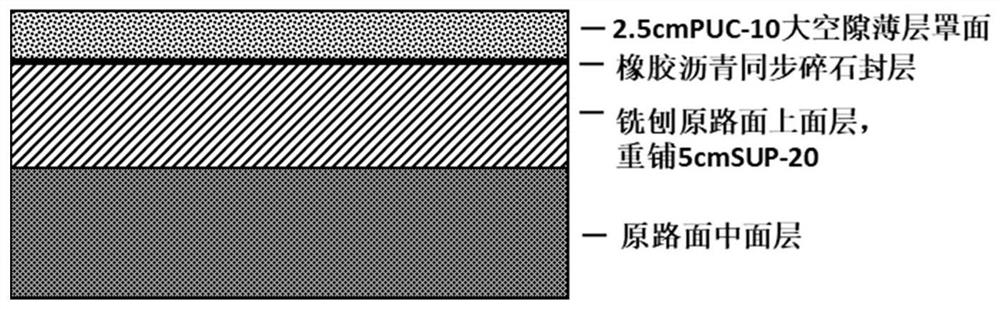

[0039] The implementation of the present invention is described by taking the drainage asphalt pavement maintenance of Jiangsu Coastal Expressway. It has been 13 years since the high-speed drainage asphalt pavement was opened to traffic. In order to further improve the safety performance of the road surface in rainy days, a PUC-10 large-gap thin-layer cover is paved to maintain and repair the drainage asphalt pavement. Pavement improvement technology solutions such as figure 1 shown. The design porosity of PUC-10 large-void thin-layer overlay is 20.0%, and the thickness is 2.5cm.

[0040] The construction steps of PUC-10 large void thin layer overlay are as follows:

[0041] 1. Preparation before construction: Prepare basalt coarse aggregate, limestone fine aggregate, limestone powder, SBS modified asphalt, high viscosity additives, polyester fiber, use modified asphalt and pre-wrapped crushed stone as a waterproof bonding layer; , in terms of mass, the amount of high-visco...

Embodiment 2

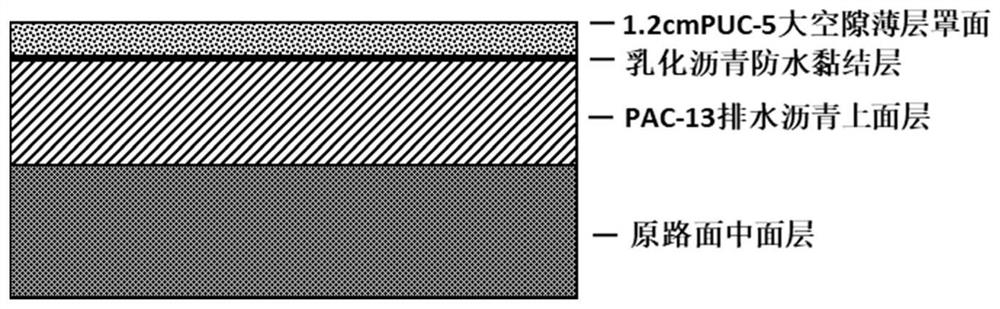

[0063] The implementation of the present invention will be described with the drainage asphalt pavement maintenance of Jiangsu Yanjing Expressway. In order to repair the local scattering disease of the drainage asphalt pavement, the drainage asphalt pavement is maintained and repaired by paving the PUC-5 large-void thin-layer cover, and the technology is verified and summarized. Pavement improvement technology solutions such as figure 1 shown. The designed porosity of the PUC-5 large-void thin-layer overlay is 18.0%, and the thickness is 1.2cm.

[0064] The construction steps of PUC-5 large void thin layer overlay are as follows:

[0065] 1. Preparation before construction: prepare basalt coarse aggregate, limestone fine aggregate, limestone powder, SBS modified asphalt, high-viscosity additives, polyester fiber, and use high-viscosity modified emulsified asphalt as a waterproof bonding layer; among them, the quality Calculated, the amount of high-viscosity additives accoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com