Method for reducing peeling risk of photoresist of ion implantation layer

An ion implantation, photoresist technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0042] step one:

[0043] Obtain the design layout of the 45nm technology node active region layer, polysilicon layer, ion implantation layer and all avoidance layers, and mark the allowable addition area in the design layout that allows the addition of polysilicon device auxiliary graphics through logical operations.

[0044] Step two:

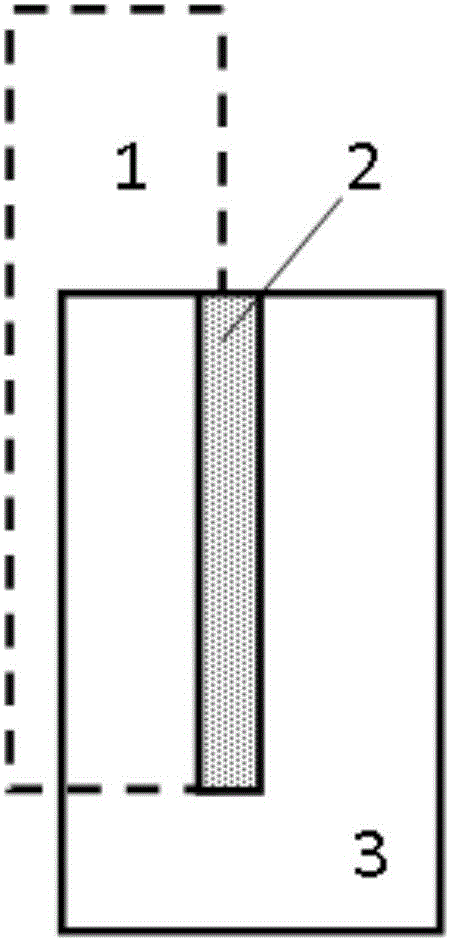

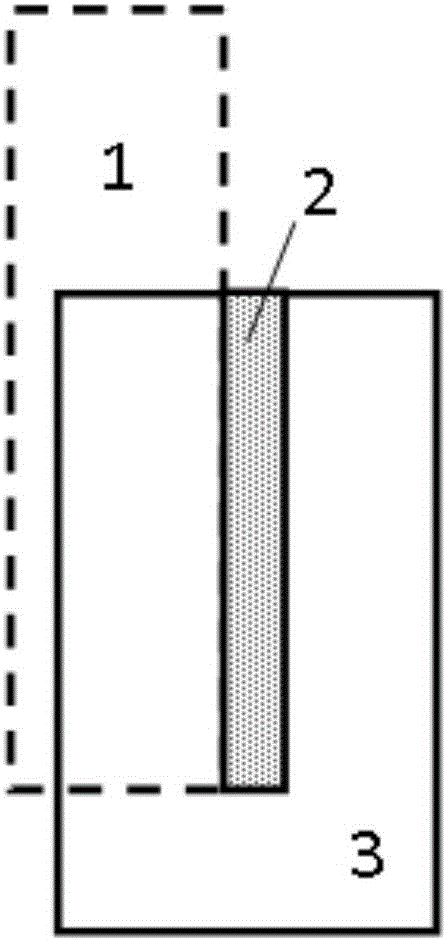

[0045] Automatically find the long side of the ion implantation layer whose length is greater than or equal to 180nm, and then generate a rectangular auxiliary pattern of the original polysilicon device with a width of 40nm and close to the outside of the long side in the allowable addition region.

[0046] Step three:

[0047]Judging the area and the distance between the auxiliary graphics of a single original polysilicon device, marking the area less than 22000nm2 or the distance between each other is less than 100nm and clearing the auxiliary graphics of the original polysilicon device, and the rest is the auxiliary graphics of the polysi...

specific Embodiment 2

[0049] step one:

[0050] Obtain the design layout of the 28nm active region layer, polysilicon layer, ion implantation layer and all avoidance layers, and mark the allowable addition area in the design layout that allows auxiliary graphics of polysilicon devices to be added through logical operations.

[0051] Step two:

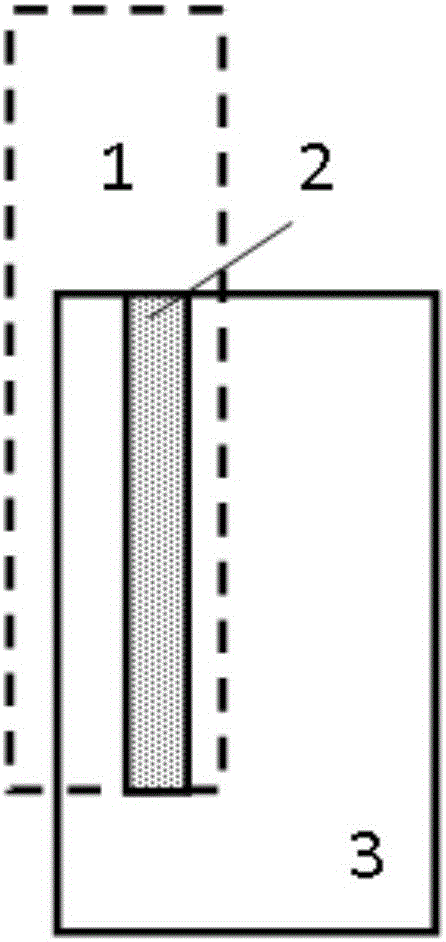

[0052] Automatically find the long side of the ion implantation layer with a length greater than or equal to 144nm, and then generate polysilicon device auxiliary patterns along the long side in the allowable addition area, with a width of 27nm, of which 9nm is within the long side and 18nm is outside the long side.

[0053] Step three:

[0054] Judging the area and the distance between the auxiliary graphics of a single original polysilicon device, marking the area less than 11500nm2 or the distance between each other is less than 100nm and clearing the auxiliary graphics of the original polysilicon device, and the rest is the auxiliary graphics of the pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com