Bipolar membrane based on pre-modified metal organic framework material and preparation method and application thereof

A metal-organic framework, bipolar membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. The effect of reducing the amount of impurities, reducing the film surface resistance, and solving the agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of sulfonated polyethersulfone: Dissolve 10 g polyethersulfone in 30 ml dimethyl sulfoxide, stir until completely dissolved, add 5.5 ml chlorosulfonic acid dropwise, stir at room temperature for 5 h, and then dissolve the solution Introduce a large amount of ice water, wash repeatedly until the pH of the solution is 6~7, and then dry at 60°C to constant weight.

[0034](2) Preparation of amino-modified metal-organic frameworks: Dissolve 1.742 g of 2-aminoterephthalic acid and 1.622 g of ferric chloride hexahydrate in 80 ml of N, N-dimethylformamide, and sonicate for 0.5 h Afterwards, it was transferred to a 100 ml reaction kettle, kept at 180 °C for 24 h, and cooled to room temperature, then the product was centrifuged and washed three times with excess N, N-dimethylformamide, and finally at 60 Dry under vacuum for 48 h.

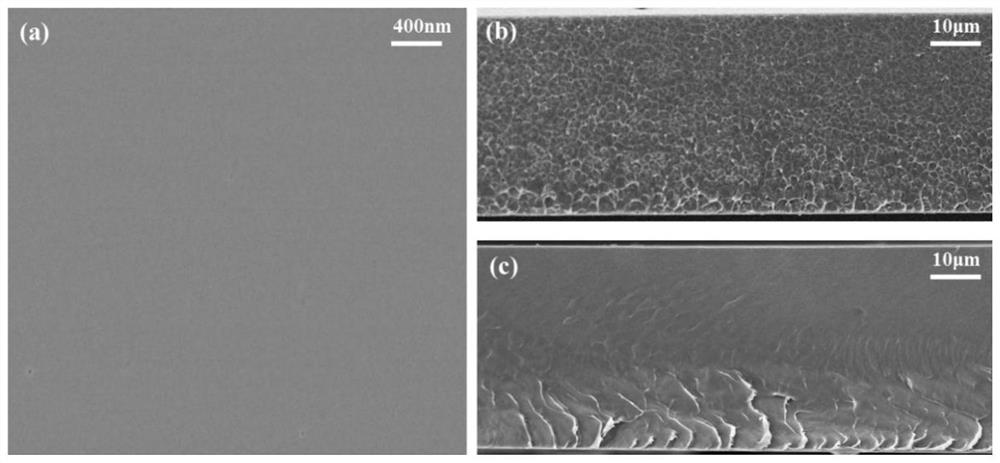

[0035] (3) Preparation of casting solution: 3.96 g of sulfonated polyethersulfone and 0.04 g of amino-modified MOF particles prepare...

Embodiment 2

[0038] (1) Preparation of sulfonated polyethersulfone: Dissolve 10 g polyethersulfone in 30 ml dimethyl sulfoxide, stir until completely dissolved, add 4.5 ml fuming sulfuric acid dropwise, stir at room temperature for 6 h, and then dissolve the solution Introduce a large amount of ice water, wash repeatedly until the pH of the solution is 6~7, and then dry at 60°C to constant weight.

[0039] (2) Preparation of amino-modified metal-organic frameworks: Dissolve 1.742 g of 2-aminoterephthalic acid and 1.622 g of ferric chloride hexahydrate in 80 ml of N, N-dimethylformamide, and sonicate for 0.5 h Afterwards, it was transferred to a 100 ml reaction kettle, kept at 180 °C for 24 h, and cooled to room temperature, then the product was centrifuged and washed three times with excess N, N-dimethylformamide, and finally at 60 Dry under vacuum for 48 h.

[0040] (3) Preparation of casting solution: 3.92 g of sulfonated polyethersulfone and 0.08 g of amino-modified metal-organic frame...

Embodiment 3

[0043] (1) Preparation of sulfonated polyethersulfone: Dissolve 10 g polyethersulfone in 30 ml N, N-dimethylacetamide, stir until completely dissolved, then add 4.5 ml oleum dropwise, and stir at room temperature for 5 h , and then the solution was introduced into a large amount of ice water, washed repeatedly until the solution pH=6~7, and then dried at 60°C to constant weight.

[0044] (2) Preparation of amino-modified metal-organic frameworks: Dissolve 0.924 g of 2-aminoterephthalic acid and 1.622 g of ferric chloride hexahydrate in 80 ml of N, N-dimethylacetamide, and sonicate for 0.5 h Afterwards, it was transferred to a 100 ml reaction kettle, kept at 180°C for 48 h, and cooled to room temperature, then the product was centrifuged and washed three times with excess N, N-dimethylformamide, and finally at 60 Dry under vacuum for 48 h.

[0045] (3) Preparation of casting solution: 3.88 g of sulfonated polyethersulfone and 0.12 g of amino-modified metal-organic framework pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com