Lifting and sliding mounting technology for platform large equipment

A technology for large-scale equipment and installation technology, applied in hoisting devices, artificial islands, water conservancy projects, etc., can solve the problems of unguaranteed construction period, high installation cost, and insufficient capacity, so as to improve the quality of engineering construction, reduce operating costs, and shorten construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention adopts following steps:

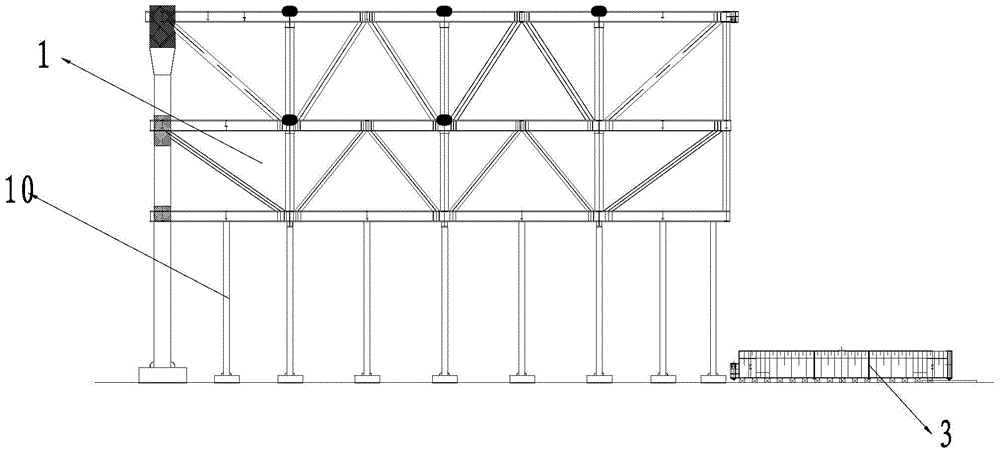

[0040] The first step: if figure 1 As shown, after the large upper block 1 has the conditions for installing large equipment 2, a lifting beam 3 is arranged on one side of the large upper block 1;

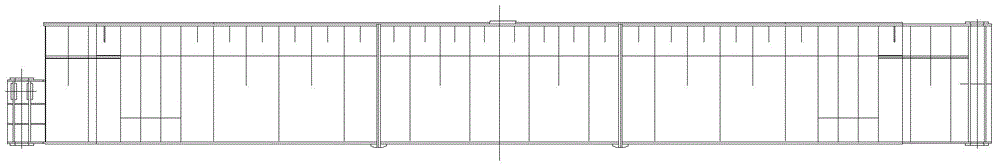

[0041] Such as figure 2 As shown, the lifting beam 3 is divided into three sections for disassembly and transportation. One end of the lifting beam 3 is designed to match the pin riveting structure of the lifting corbel 6, and the other end is convenient for the fixed anchor hole of the steel strand 9.

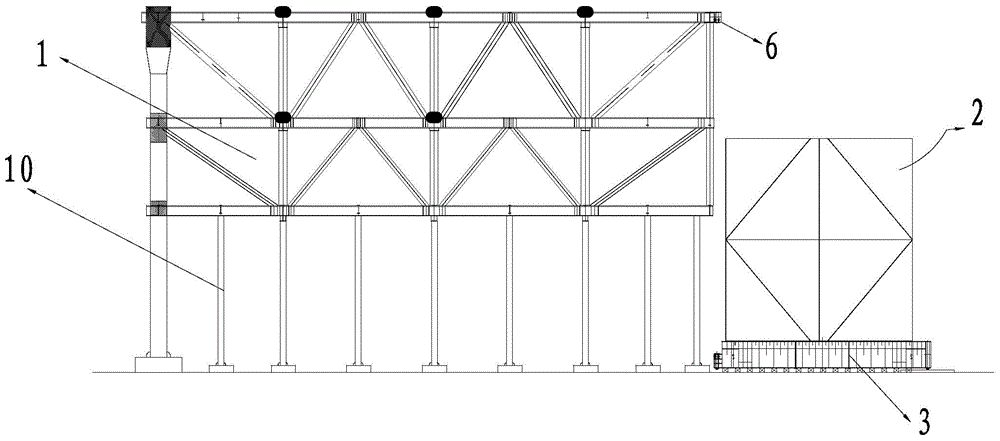

[0042] The second step: if image 3 — Figure 4 As shown, a sliding track 11 is fixed by welding on the lifting beam 3, and a slider is placed on the sliding track 11; then, the large equipment 2 is transported as a whole with a hydraulic flatbed transport vehicle and placed on the lifting beam 3 At the same time, a lifting corbel 6 is installed on the top deck girder of the large upper block 1; the lifting corbel 6 is a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com