Method for controlling thickness and flatness of concrete floor

A control method and concrete technology, which is applied in the direction of construction, building structure, and building material processing, etc., can solve the problems of uneven concrete floor surface, uneven thickness, etc., achieve effective concrete thickness and flatness, simple production, The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

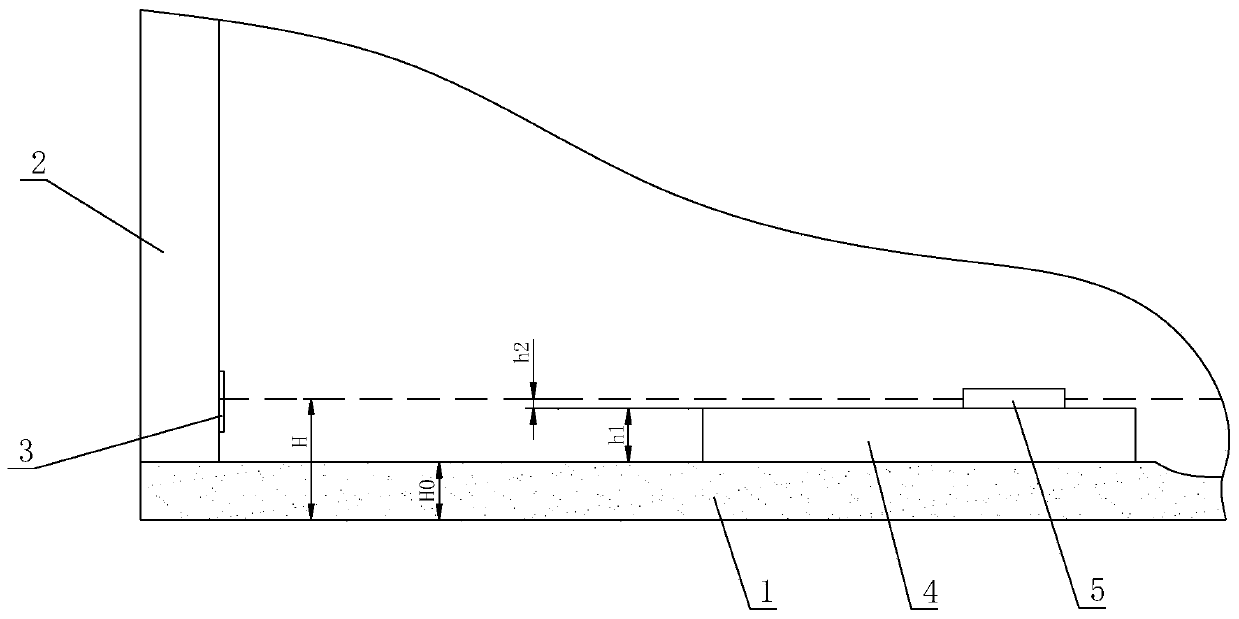

[0023] like figure 1 Shown, a kind of concrete floor slab thickness and flatness control method of the present invention comprise the steps:

[0024] 1) Use the white positioning board 3 and the laser digital display level 5 as auxiliary positioning devices, draw the floor elevation reference control line and the auxiliary control line on one side of the white positioning board 3; fix the laser digital display level 5 at the horizontal The top of the scraper bar 4; and make the laser emission direction of the laser digital display level 5 parallel to the lower surface of the horizontal scraper bar 4;

[0025] 2) Before pouring the concrete floor 2, bind the white positioning plate 3 on the frame column or the shear wall reinforcement 2, and lay the white positioning plate 3 along the columns around the concrete floor 1 and the entire length of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com