Construction method for vertically penetrating lower hanging plate of external facade

A construction method and façade technology, applied in covering/lining, construction, building structure, etc., can solve the problem that the lower hanging board is not in the design position, and achieve the effect of improving construction quality, convenient installation, and easy disassembly and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

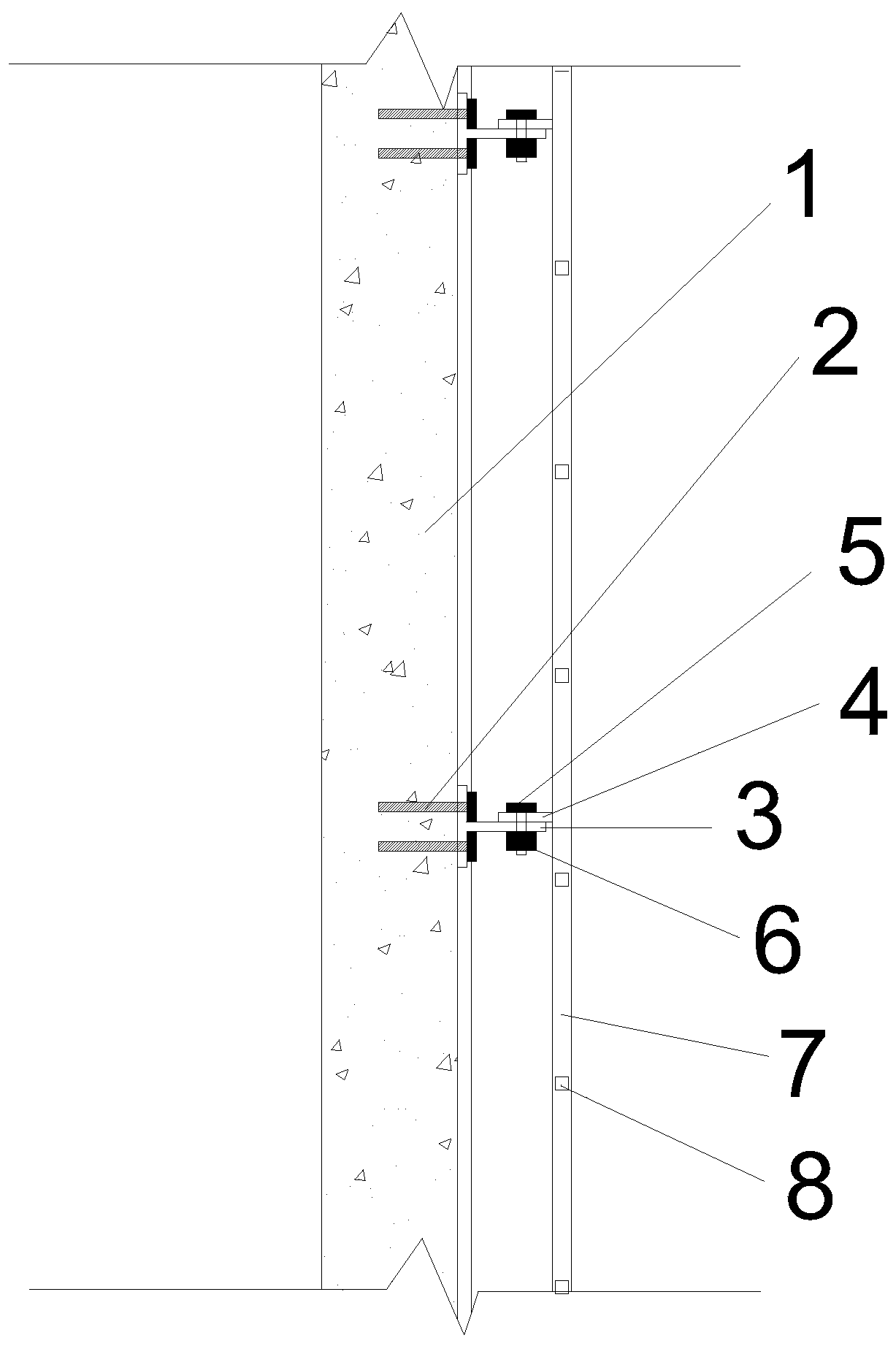

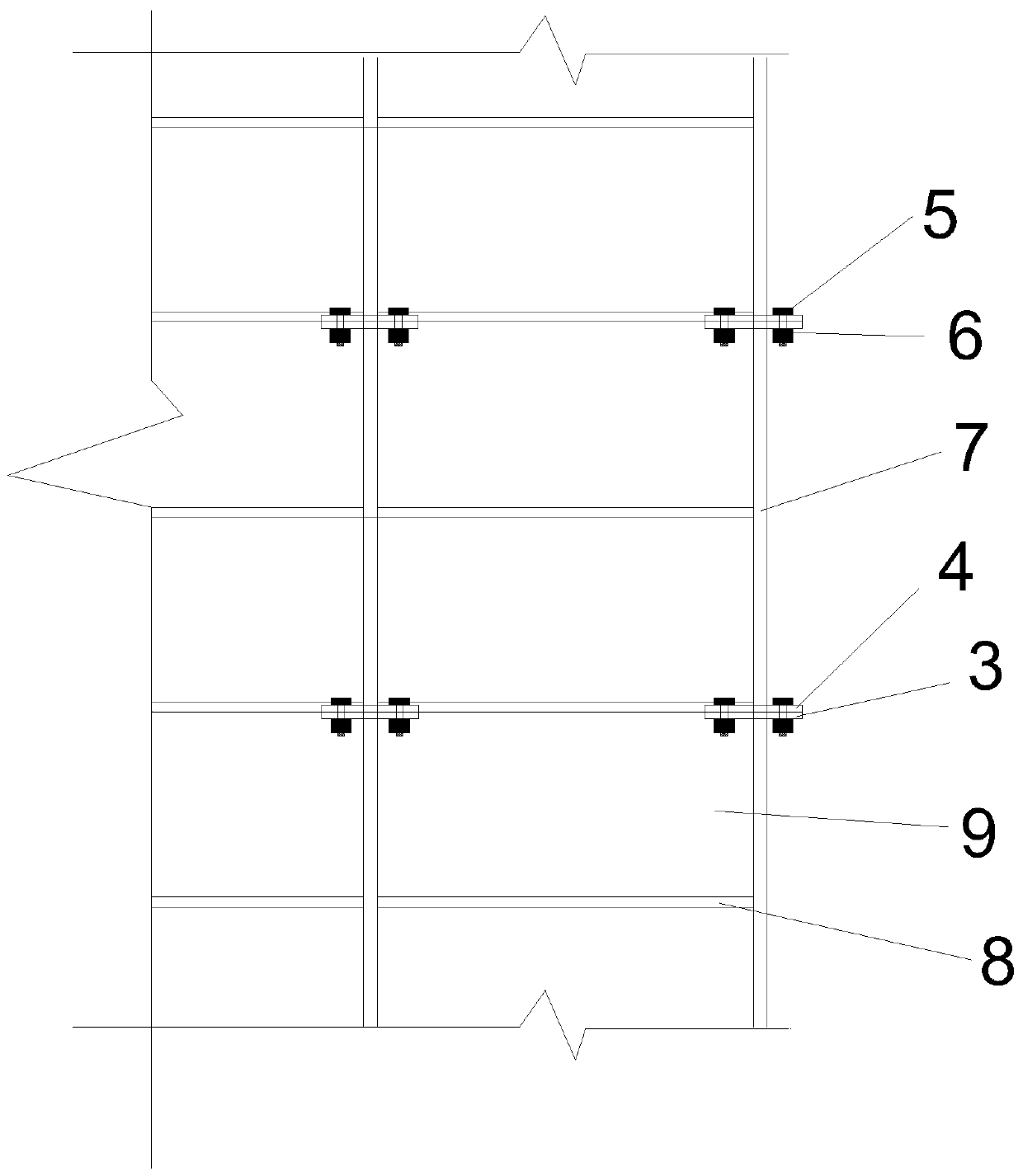

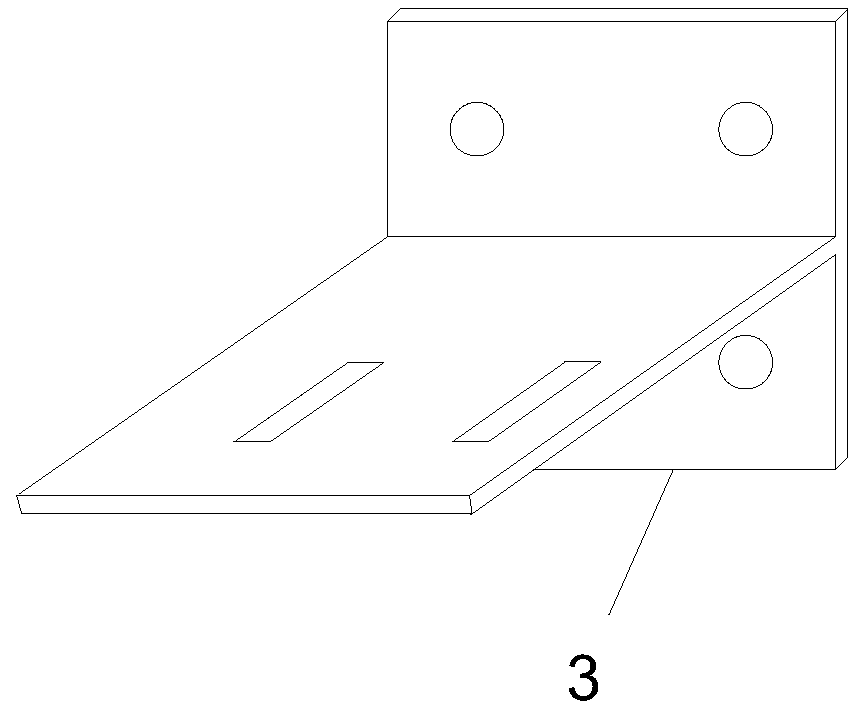

[0021] refer to Figure 1-4 , a construction method for vertically penetrating the lower hanging plate on the facade, including using expansion screws 2, shaped flat steel 3, matching steel plates 4, bolts 5, nuts 6, main joists 6, secondary joists 7, and facade hanging panels 9 and the coordinated construction of the wall 1, the shaped flat steel 3 is a T-shaped structure, the shaped flat steel 3 includes a top steel plate and a facade steel plate, the top steel plate is provided with mounting holes, and the shaped flat steel The steel 3 is fixedly connected to the wall 1 through the expansion screw 2 at the position of the installation hole. The shaped flat steel 3 is spliced up and down through the facade steel plate and the supporting steel plate 4. Both the facade steel plate and the supporting steel plate 4 are provided with reserved hole, the shaped flat steel 3 and the supporting steel plate 4 are connected and fixed by bolts 5, one side of the supporting steel plate...

Embodiment 2

[0023] On the basis of Embodiment 1, the relative position of the shaped flat steel 3 and the supporting steel plate 4 is adjustable, and the adjustment of the positions of the shaped flat steel 3 and the supporting steel plate 4 is used to make the facade hanging plate 9 reach the design position, The thickness of the shaped flat steel 3 is 12mm, the outer diameter of the bolt 5 and the expansion screw 2 is 10mm, and the outer facade hanging plate 9 is detachably connected to the outer facade frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com