Overturn detachable floorslab concrete thickness control device

A thickness control and concrete technology, applied in construction, building structure, construction material processing and other directions, can solve the problems of lack of intuitive feedback on concrete thickness, occupying a large storage space, and being inactive, so as to improve the quality of engineering construction, Simple structure and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

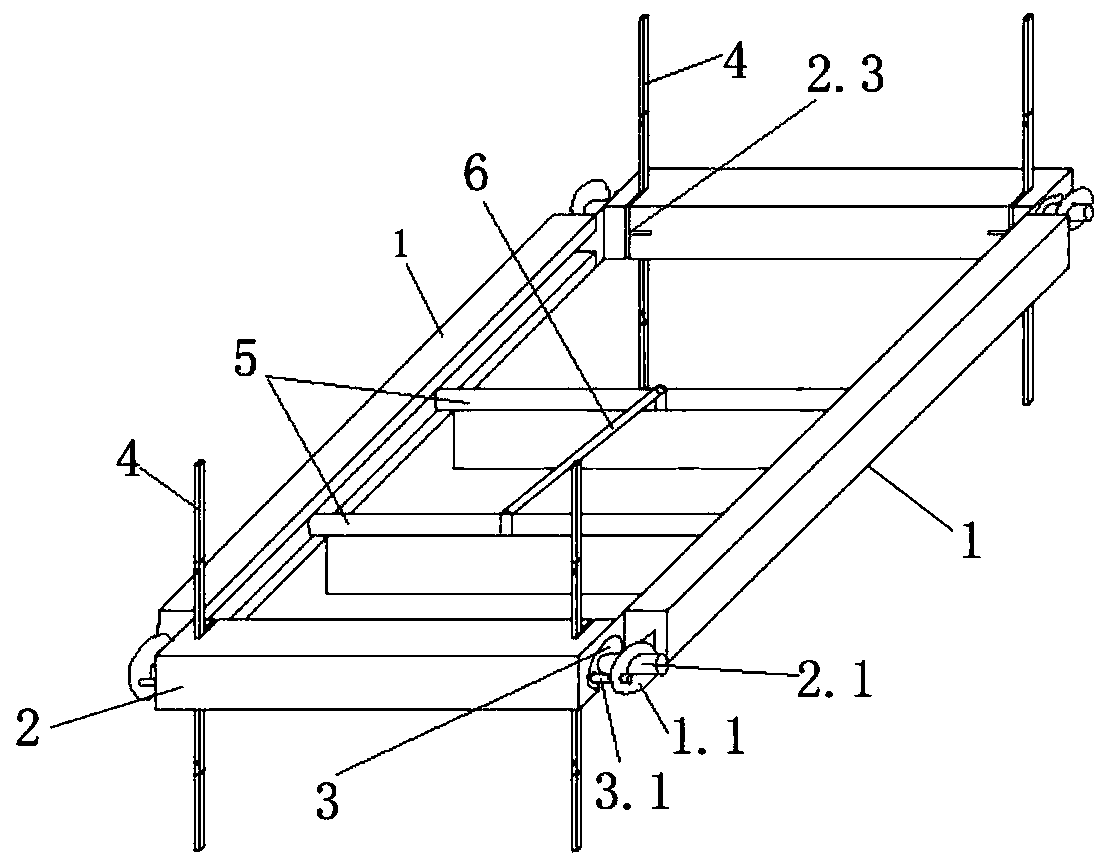

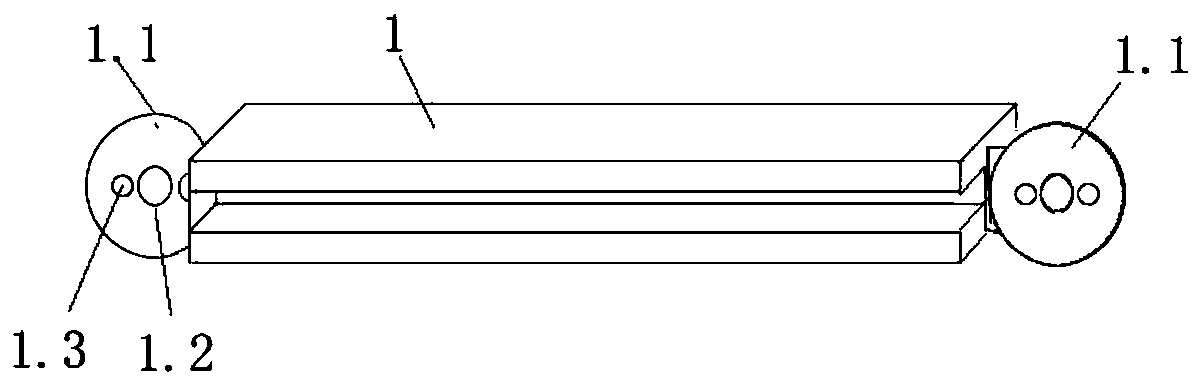

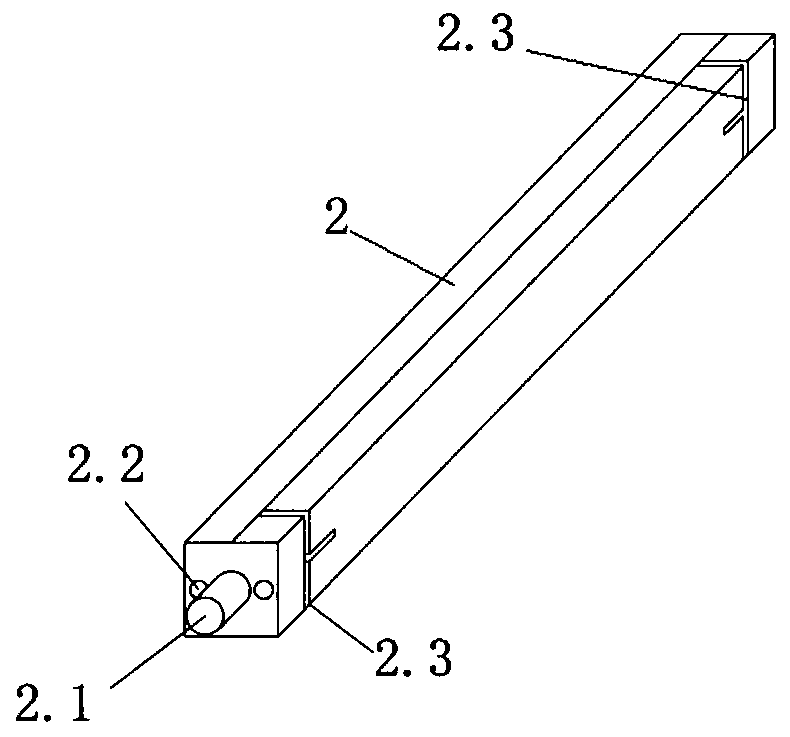

[0016] Such as figure 1 The concrete thickness control device of a flip-type detachable floor slab shown includes two symmetrically arranged grooved guide rails 1, guide rail connecting rods 2 respectively arranged at both ends of the two guide rails, and bayonets that can be fitted to both ends of the guide rail connecting rods. Fixing member 3. A total of four two-way measuring feet with scales and adjustment holes respectively arranged at both ends of the connecting rods of the guide rails 4. Two parallel scraping rulers arranged between the two guide rails and inside the connecting rods of the two guide rails 5. Both ends are clamped on the scraping ruler push rod 6 on the back of the scraping ruler.

[0017] The notches of the two grooved guide rails 1 are arranged oppositely, such as figure 2 As shown, one end of the grooved guide rail is closed, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com