A column formwork support component

A column formwork and component technology, which is applied to the field of column formwork enclosure support components, can solve problems such as engineering defects, support, and affect the quality of engineering construction, and achieve the effects of effective support, stable structure, and improvement of engineering construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

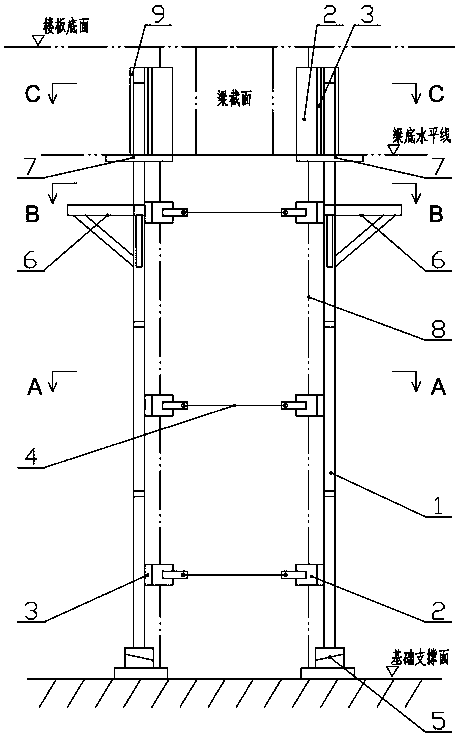

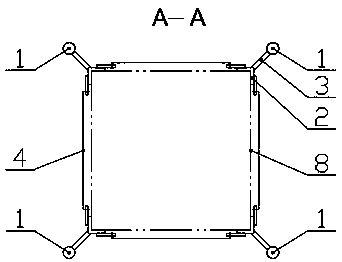

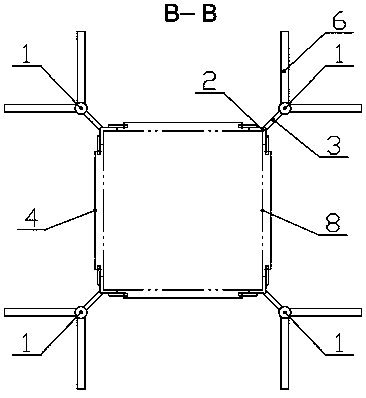

[0029] Taking the column template 8 with a square cross section as an example, as Figure 1 to Figure 4 As shown, the column formwork support assembly of the present invention includes four support poles 1, and the support poles 1 are respectively located on the column angle bisector of the column formwork.

[0030] Several column corner sealing hoop plates 2 are arranged at intervals on each supporting pole 1 , and in this embodiment, the column corner sealing hoop plates are right-angled angle plates. The angle of the column corner sealing hoop plate 2 is adapted to the column angle (right angle) of the column formwork, so that it can be fastened on the column angle of the column formwork.

[0031] figure 1 Among them, four column corner sealing hoop plates 2 are arranged at intervals on each supporting pole 1 . Among them, three column corner sealing hoop plates 2 are arranged on the middle and lower part of the surrounding support pole; another column corner sealing hoop...

Embodiment 2

[0041] Take the circular column formwork 10 as an example to illustrate, as Figure 5 to Figure 8 As shown, the column formwork support assembly of the present invention includes several support poles 1 , and the support poles 1 are evenly distributed on the outer periphery of the circular column formwork 10 .

[0042] Arc-shaped hoop plates 11 are arranged at intervals on the surrounding support pole 1, and the arc of the arc-shaped hoop plates 11 is adapted to the arc of the circular column formwork 10, so that the arc-shaped hoop plates can be buckled on the On the peripheral wall of the circular column formwork.

[0043] Adjacent arc-shaped hoop plates 11 at the same height are connected to each other through telescopic arc-shaped tie rods 12, thereby forming a support body that is hooped outside the column formwork.

[0044] Of course, due to the existence of the beam formwork, no telescopic tie rod is arranged between the adjacent arc-shaped hoop plates located on the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com