Slag pot tipping feeder

A technology of feeding device and slag tank, which is applied in the field of automatic tipping and feeding device of slag tank, can solve the problems of unstable operation, affecting operation, occupying workshop cranes, etc., so as to increase operational reliability, prevent sudden tipping and reduce accidents hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

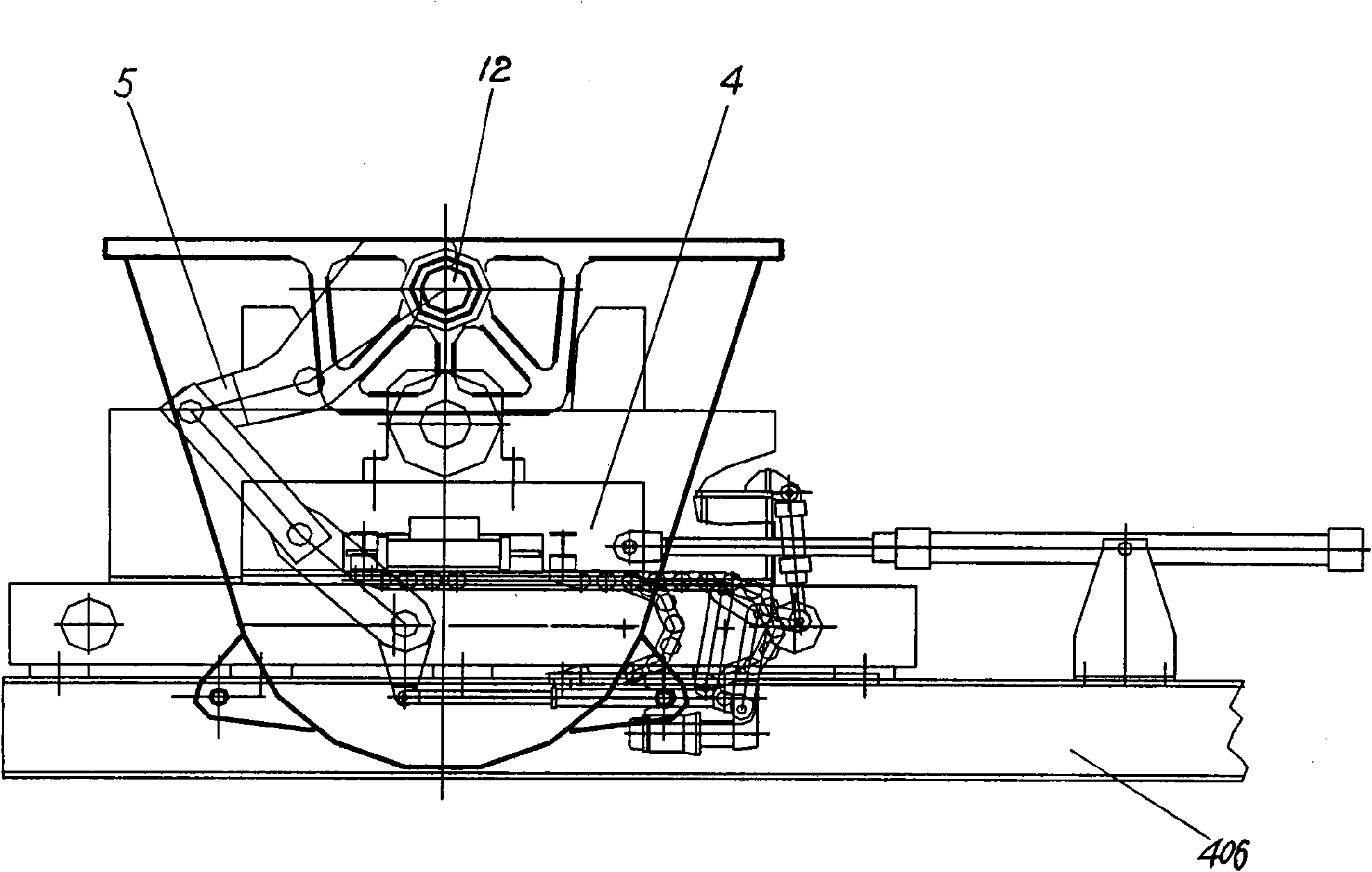

[0035] A preferred embodiment of a slag tank tipping feeding device of the present invention will be specifically introduced below in conjunction with the accompanying drawings.

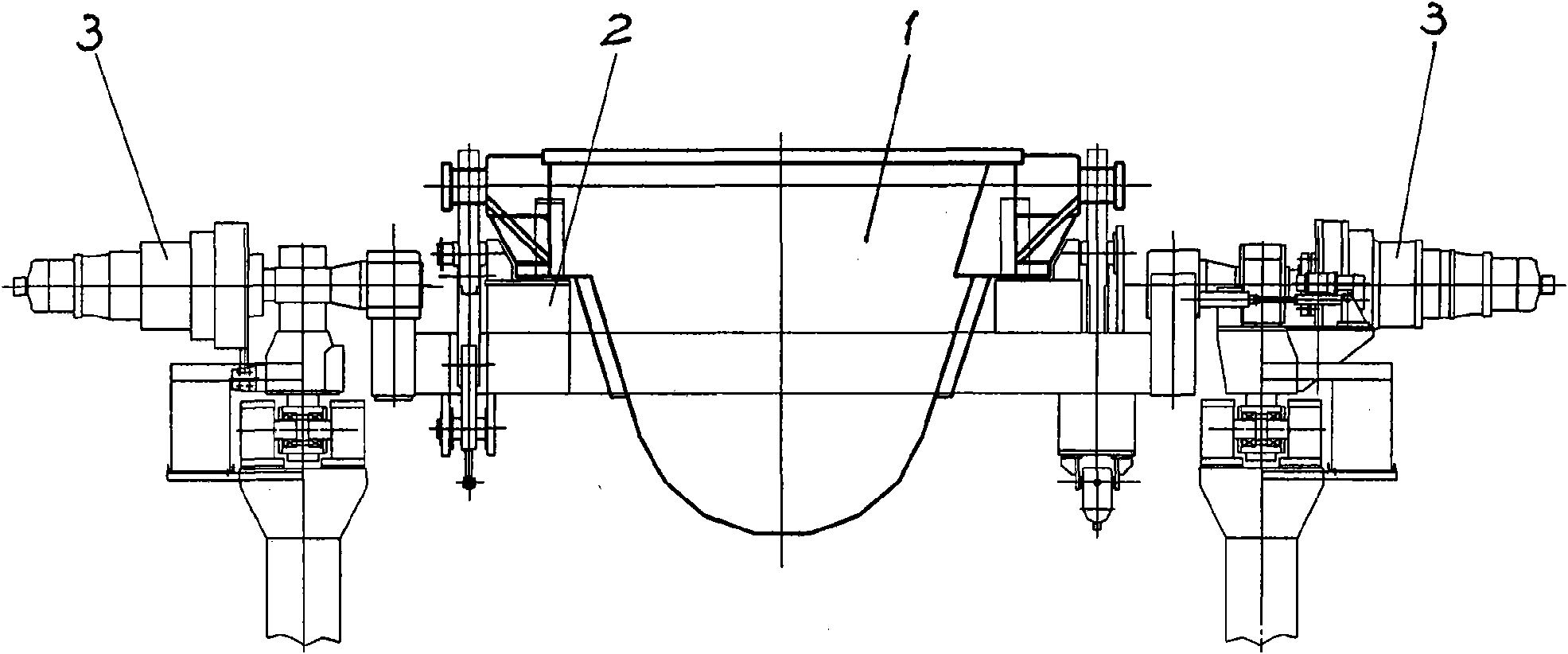

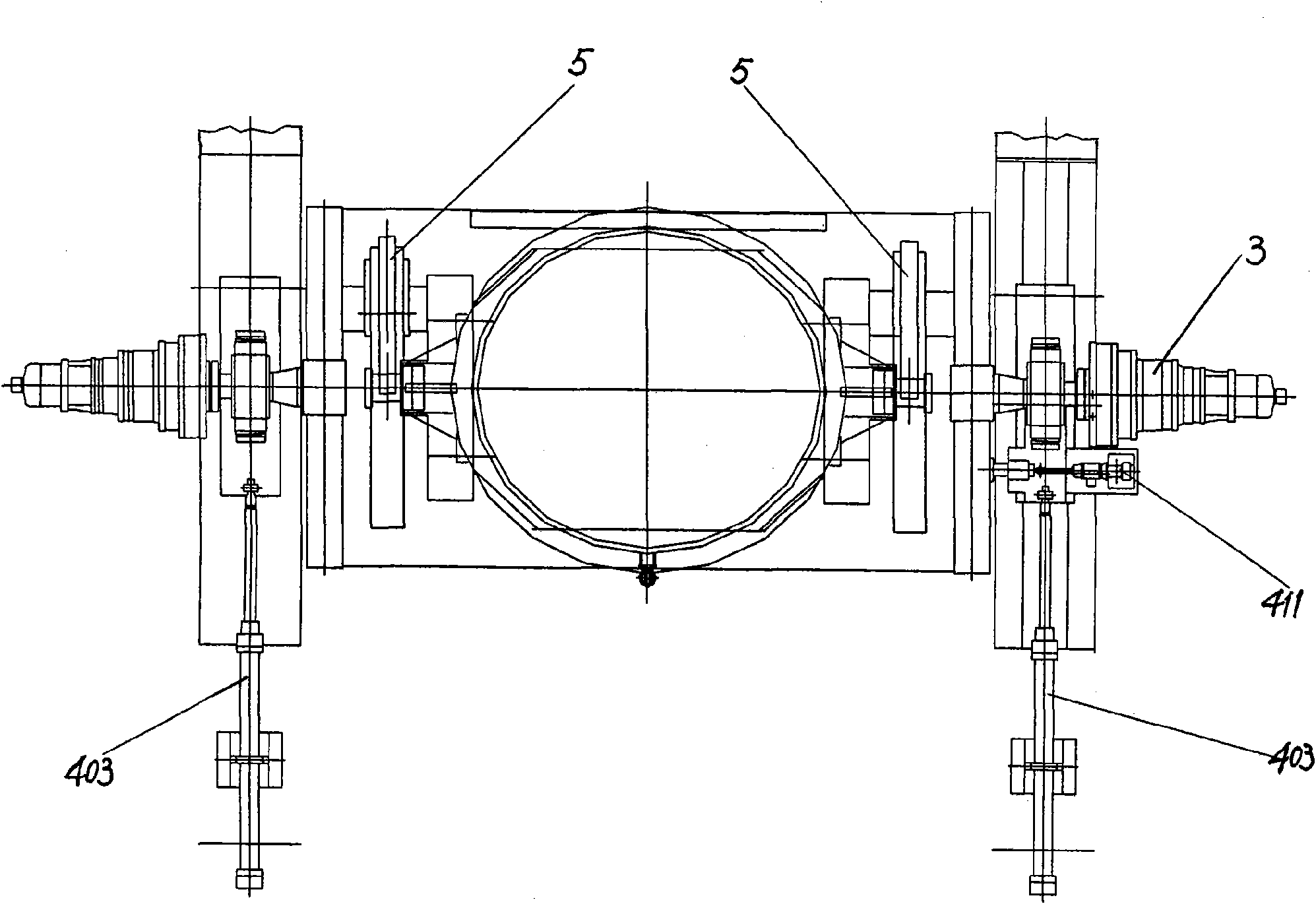

[0036] see Figure 1 to Figure 4 , a slag tank tipping feeding device of the present invention is used for tipping a slag tank 1 with two trunnions 12 . The slag tank tipping and feeding device consists of two translation devices 4, two clamping mechanisms 5, a supporting tipping frame 2, two transmission devices 3, a card slot mechanism and a locking mechanism respectively installed on two parallel bracket beams 406. 411 composition.

[0037] The support tipping frame 2 is a ring frame, which is installed on the elevated crossbeam. Four columns, two installation crossbeams and connecting beams on both sides form a frame structure to ensure sufficient support strength and rigidity. Platform railings are set on the same side of the beam, and there is a ladder on one side to facilitate maintenance an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com