Non-return valve, in particular for medical uses

a non-return valve technology, applied in the field of non-return valves, can solve the problems of delay in valve closure and diaphragm sucking on the support, and achieve the effect of valve closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

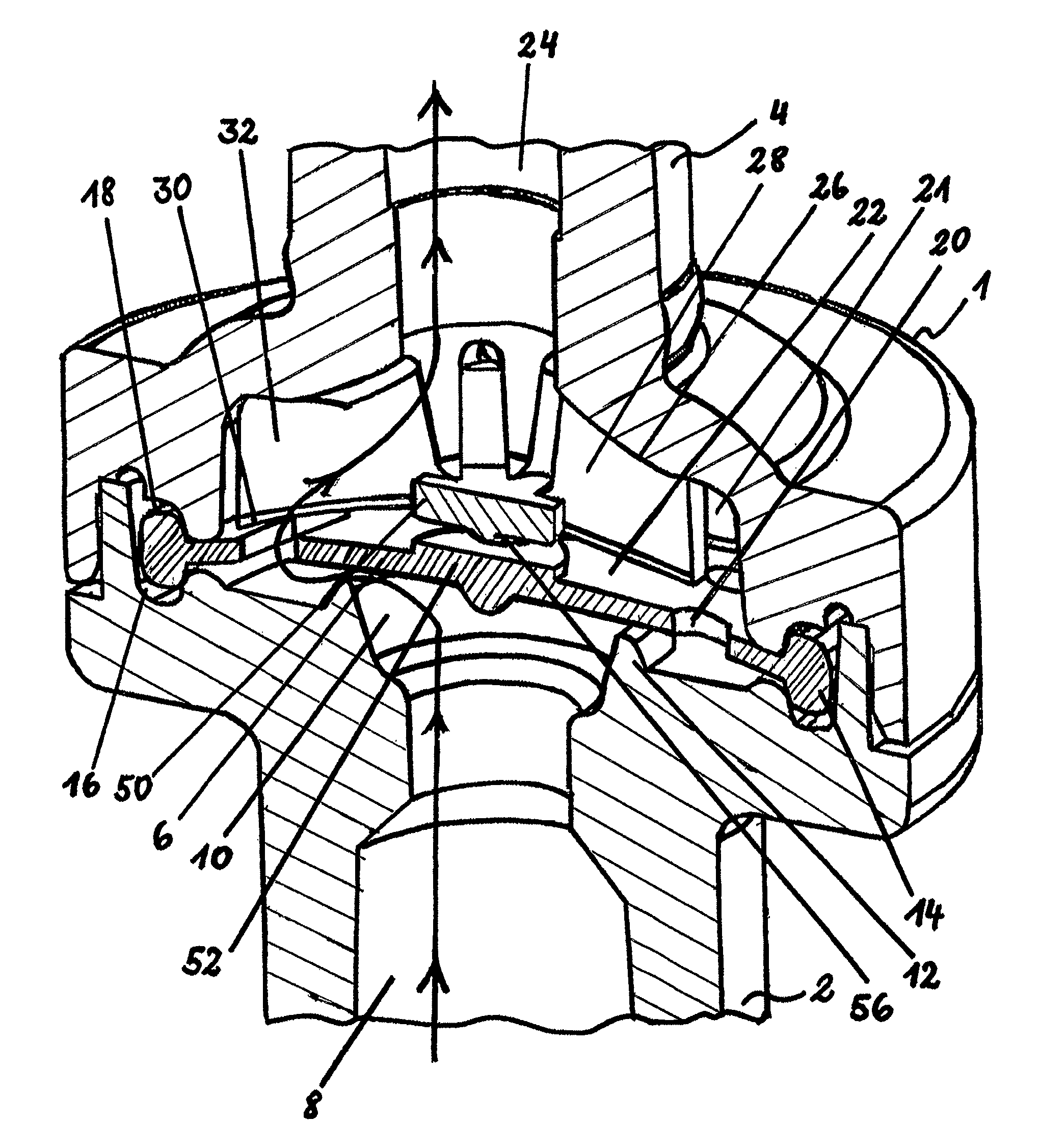

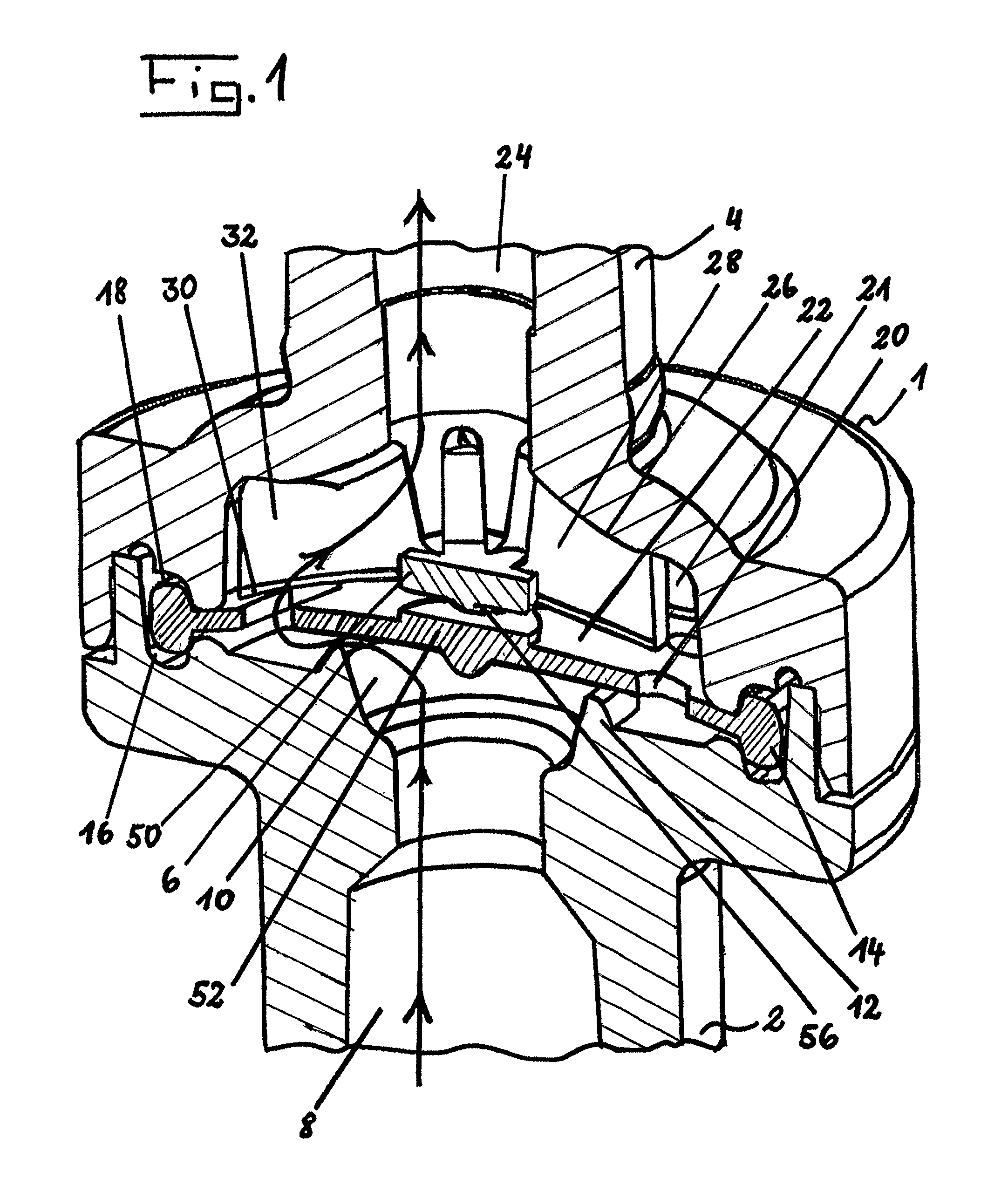

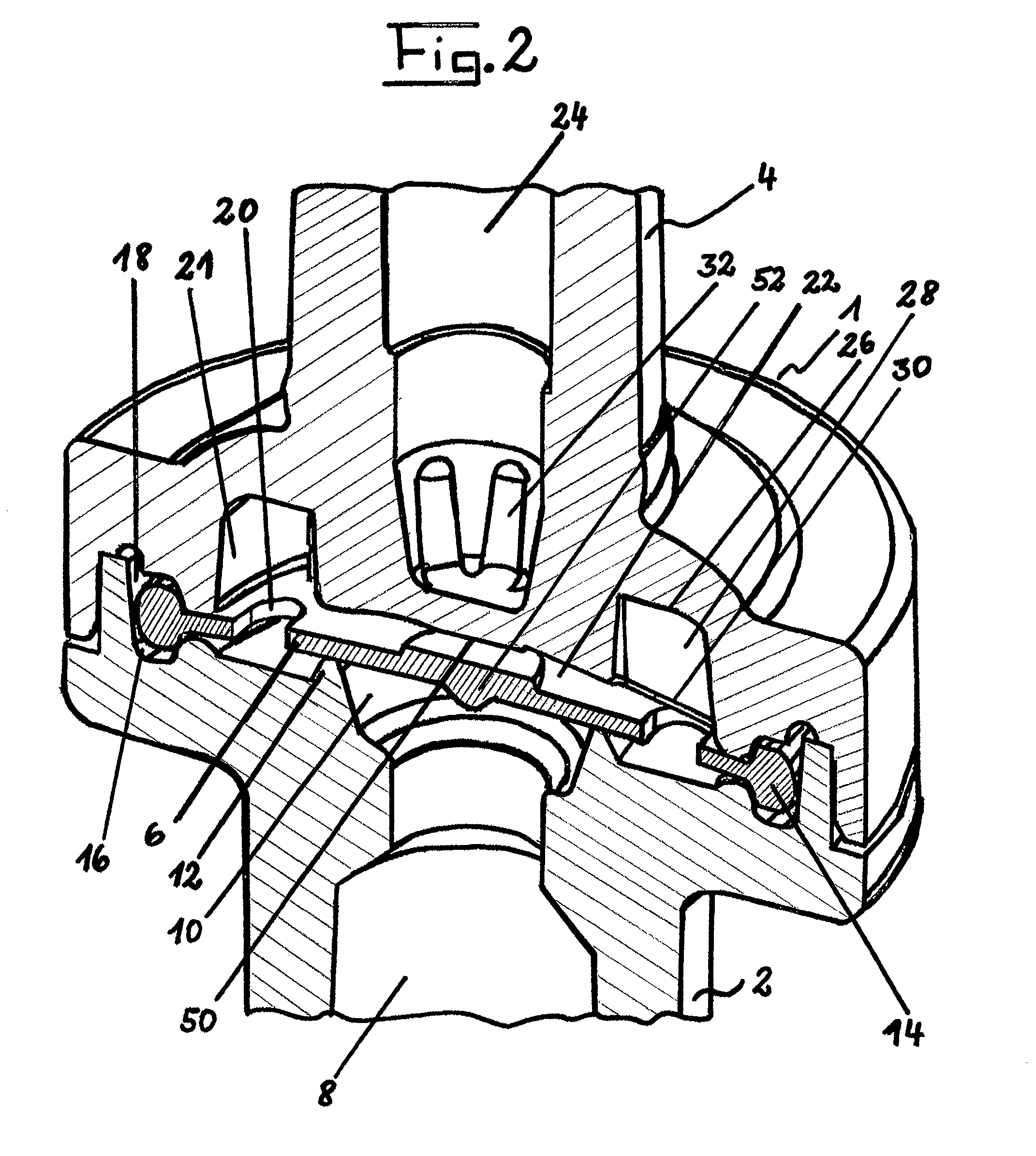

[0021]The nonreturn valve 1 shown greatly enlarged in the drawings is suitable in particular for the field of medicine and can be used, for example, at pressure differences of as low as 0.002 bar. The nonreturn valve 1 is composed of a first tube connection housing 2 and of a second tube connection housing 4, which are preferably produced from plastic by injection molding. A diaphragm disk 6 made from a flexible plastic, for example silicone, is arranged between the two tube connection housings 2 and 4.

[0022]In the first tube connection housing 2, an inlet channel 8 is formed which opens into an inlet chamber 10. The inlet chamber 10 is surrounded by an annular valve seat 12, against which the diaphragm disk 6 is pretensioned.

[0023]The diaphragm disk is designed with a continuously closed central part, which allows considerable tensile forces to be transmitted radially from the inside outward, and vice versa. At its outer peripheral area, the diaphragm disk 6 is provided with an int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com