Turnover concrete silo structure steel bar accurate positioning device and method

A precise positioning and concrete technology, which is applied in building construction, on-site preparation of building components, formwork/formwork/working frame, etc., can solve problems such as fixed positioning of steel bars, hidden dangers of defects, and structural strength not up to standard. Achieve the effects of avoiding secondary rework, flexible and convenient disassembly, and high promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

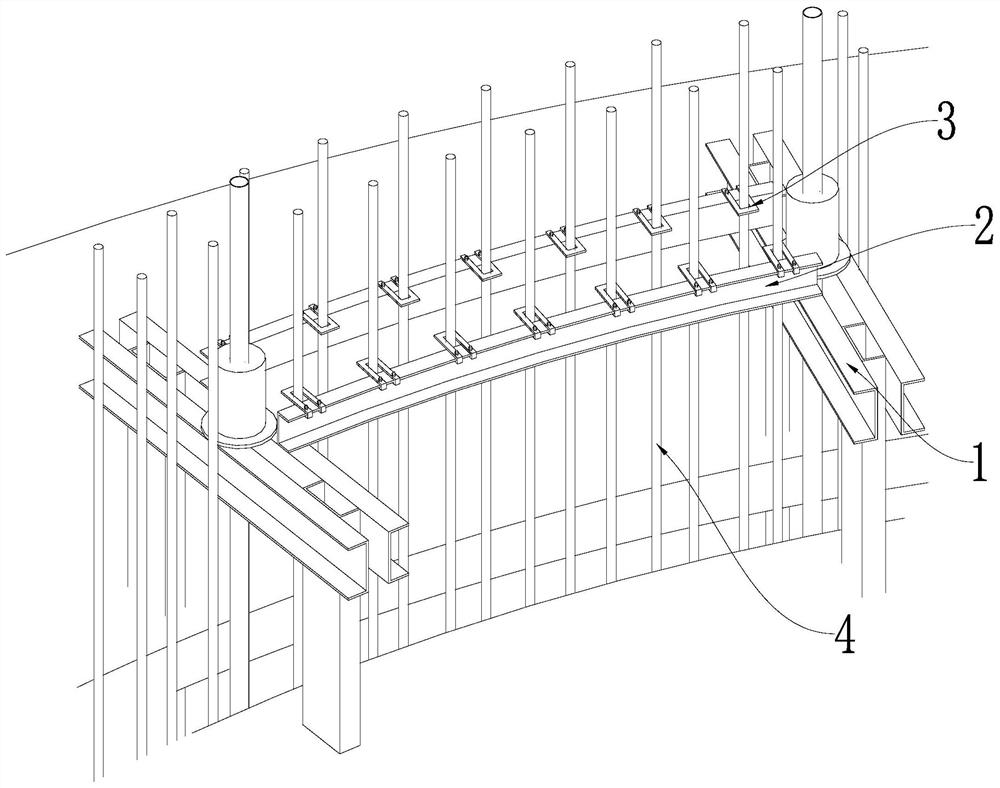

[0033] Example 1: See Figure 1 to Figure 4 , a precise positioning device for the steel bars of a turnable concrete silo structure in this embodiment, a fixed channel steel 2 is arranged across the sliding formwork operation platform 1, and a plurality of detachable guiding and positioning steel plates 3 are arranged on the fixed channel steel 2, and the guide The positioning steel plate 3 is provided with a fixing hole 31 for socketing the steel bar 4, and the perforation direction of the fixing hole 31 is parallel to the lifting direction of the sliding form operation platform 1; Compared with the previous construction method of positioning the horizontal and vertical steel bars 4 during the main construction of the building structure, during the construction process of the concrete silo structure silo wall sliding up, the construction method of precise positioning of the concrete silo structure steel bars 4 that can be reused is adopted, and the installation is convenient ...

Embodiment 2

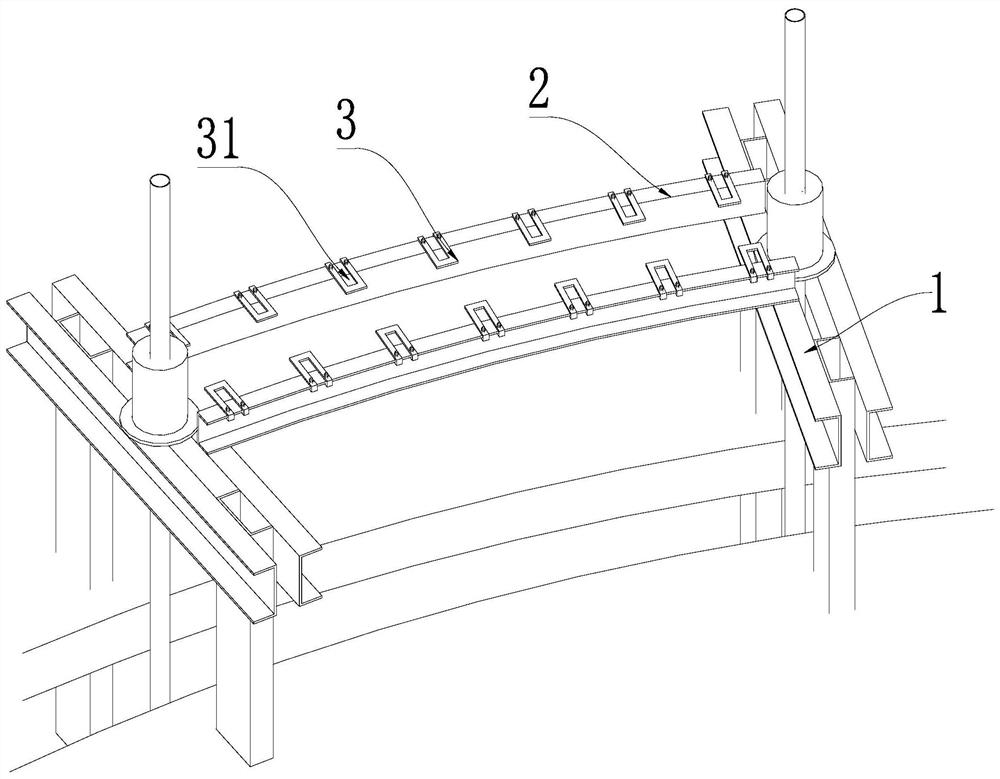

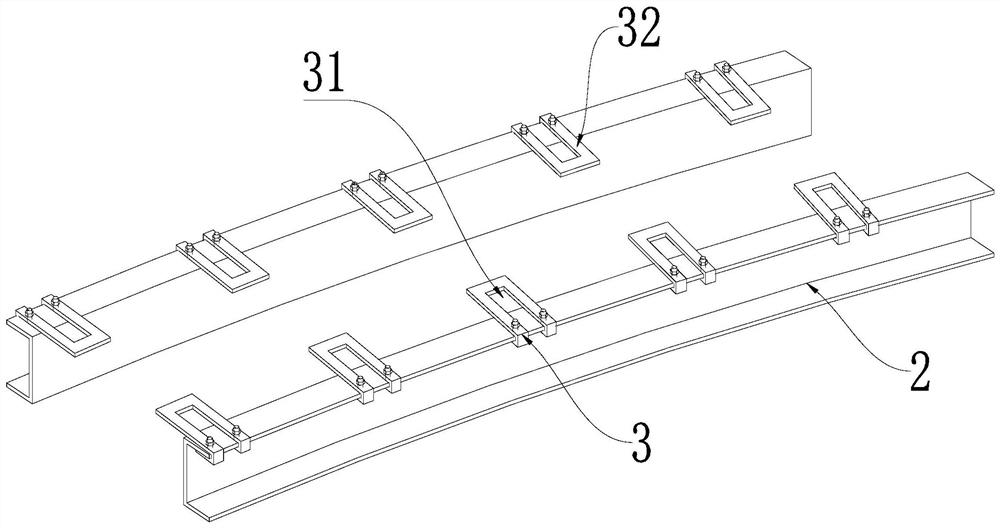

[0034]Embodiment 2: The fixed channel steel 2 of this embodiment is an arc structure, and is attached to the inner arc surface of the silo. There are two fixed channel steels 2 in this embodiment, which are arranged in parallel on the sliding form operating platform 1 . The guiding and positioning steel plates 3 on the two fixing channel steels 2 of this embodiment are arranged oppositely, and the guiding and positioning steel plates 3 are all arranged between the two fixing channel steels 2 . The guiding and positioning steel plate 3 has a U-shaped structure, and is fixed on the fixed channel steel 2 by bolt clamping. It has high strength, good fixing effect, accurate position, and the positioning device can be turned over and reused. The guiding and positioning steel plate 3 of this embodiment includes a fixing frame 32 and first fixing parts 33 arranged at both ends of the fixing frame 32 , and the first fixing part 33 is connected to the fixing channel steel 2 by bolts. A...

Embodiment 3

[0035] Embodiment 3: The fixed channel steel 2 of this embodiment is provided with a second fixing part, and the first fixing part 33 includes an upper fixing plate 331, a connecting part 332 and a lower fixing plate 333, and the upper fixing plate 331 and the lower fixing plate 333 pass through The connecting portion 332 is fixed, and the upper fixing plate 331 is parallel to the lower fixing plate 333 , and the upper fixing plate 331 and the lower fixing plate 333 are used to sandwich the second fixing portion. In this embodiment, the upper fixing plate 331 is provided with bolt holes, through which the bolts pass through the bolt holes, and then abut and fix against the second fixing part. The fixed channel steel 2 in this embodiment is provided with a circumferential dimension scale for positioning and guiding the fixed steel plate. It is used to accurately locate the distance between the vertical and horizontal steel bars 4 during the sliding process, and at the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com