Installation method of a waterproof electric thermal insulation joint

An installation method, electric heating fusion technology, applied in the direction of heat preservation, heat insulation protection of pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of low firmness of heat preservation joints, damage to polyurethane insulation layer, economic losses of heating enterprises, etc. Achieve the effects of improving engineering construction quality, low preparation cost, and reliable principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

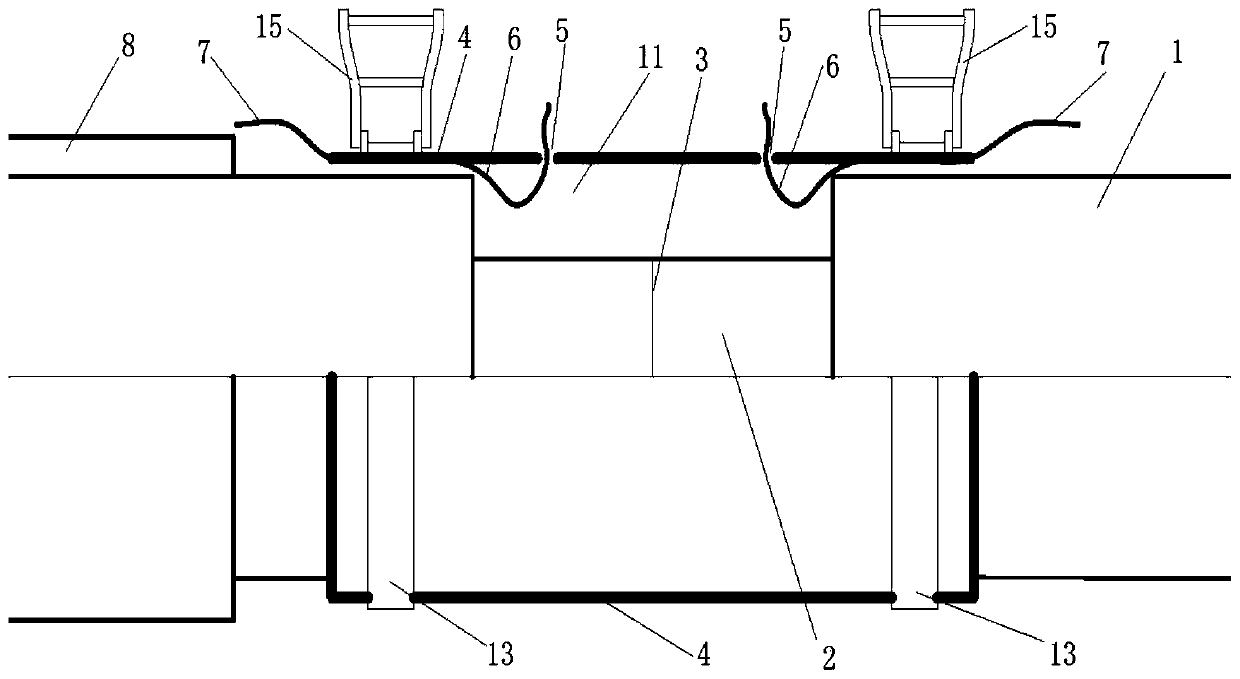

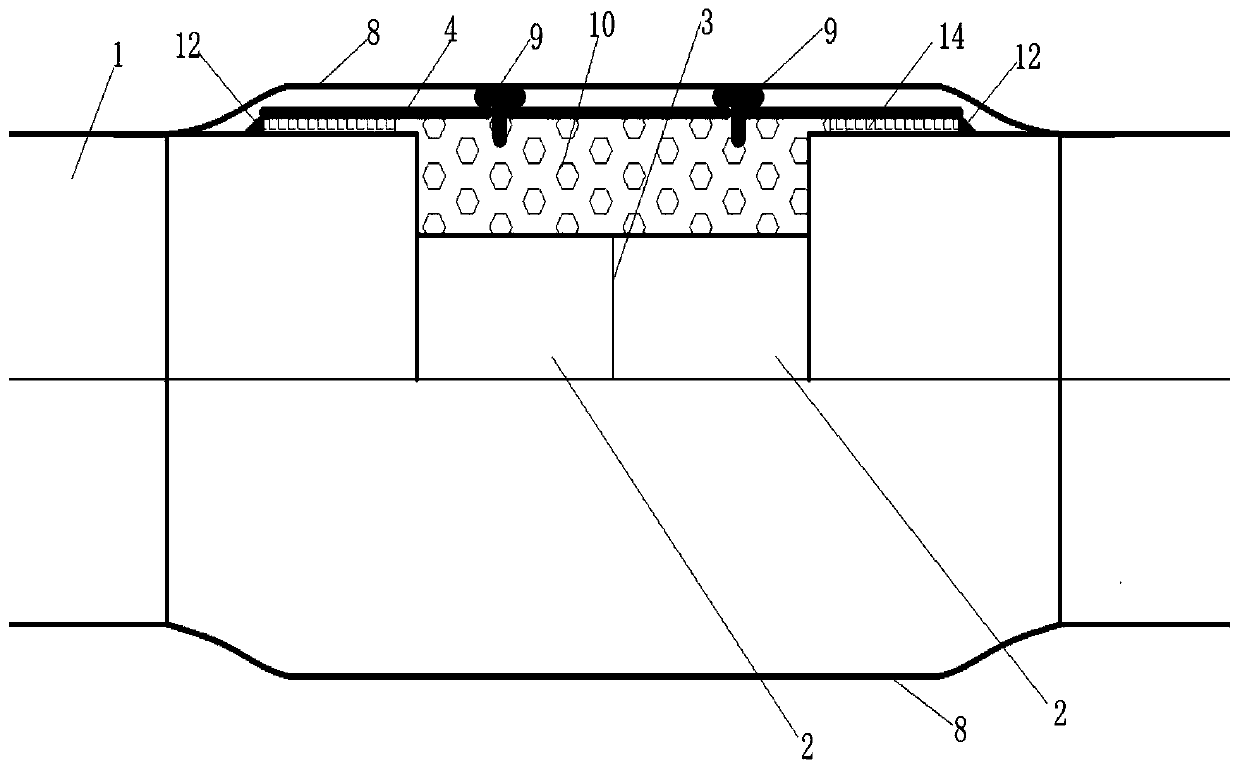

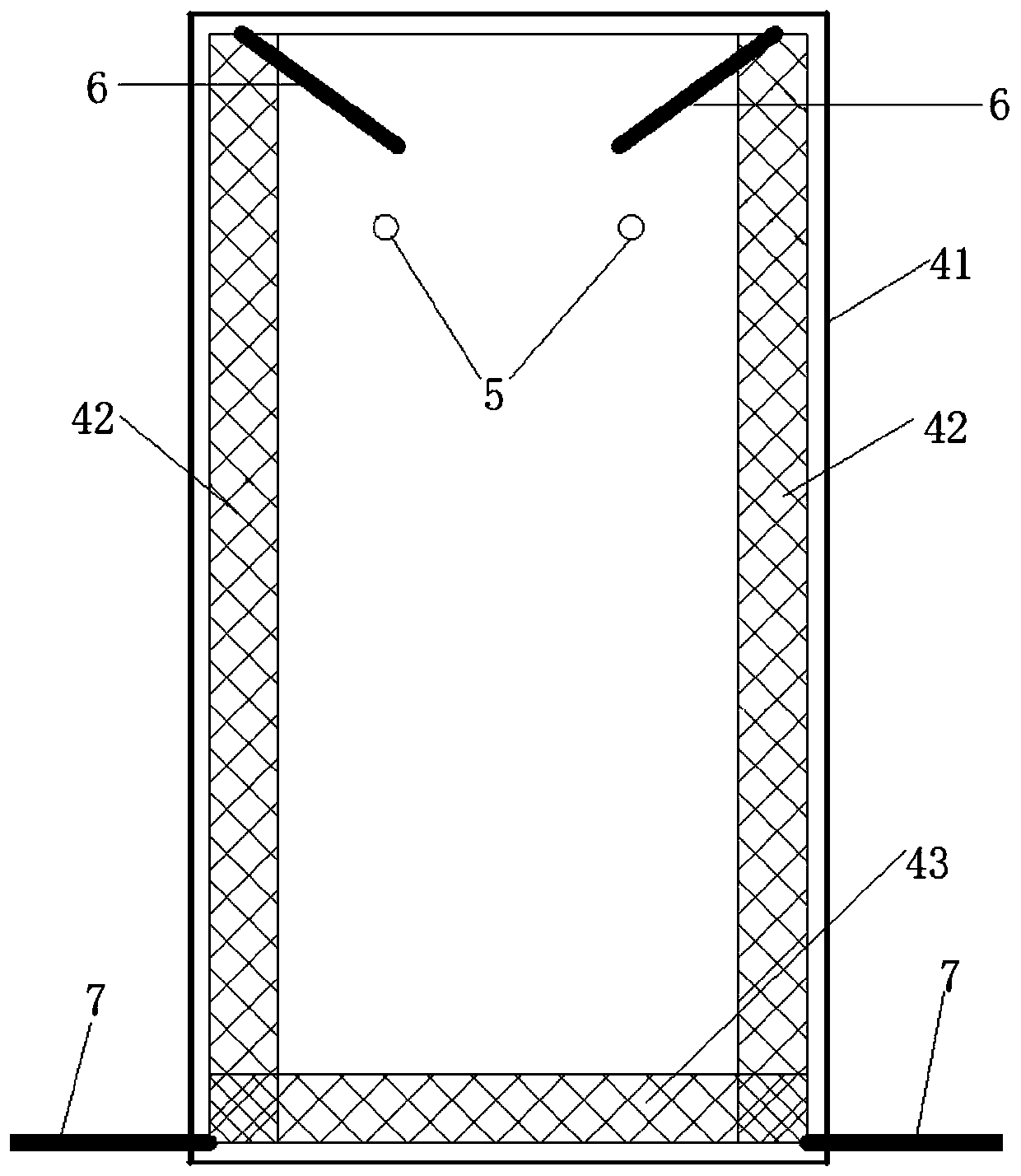

[0019] The installation process of the waterproof electric thermal insulation joint involved in this embodiment includes the following steps:

[0020] (1) Clean up the working environment: clean up the sand and sundries at the construction site, use an electric grinder to polish the surface of the steel pipe 2 and the weld seam 3 of the steel pipe, and remove the oil stains, dust, floating rust and oxide layer on the surface of the steel pipe 2; clean the PE shell 1 The width of the PE shell 1 and the electric melting sleeve 4 must be greater than the width of the contact part 200-400mm, and then wipe it clean with alcohol; use a dryer to dry the PE shell 1 and the electric melting sleeve 4 for 5-20 minutes;

[0021] (2), install the electric melting sleeve: put the electric melting sleeve 4 on the PE shell 1 at the interface, install the two clamping bands 13 on the electric melting sleeve 4, and put the two The center of the clamping band 13 is consistent with the center of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com