A method for manufacturing high-strength prestressed cast steel wire mesh

A technology of steel wire mesh sheet and production method, which is applied in the directions of building reinforcements, structural elements, building components, etc., can solve the problems of insufficient strength of steel wire mesh and inability to use high-strength steel wires, etc. The effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

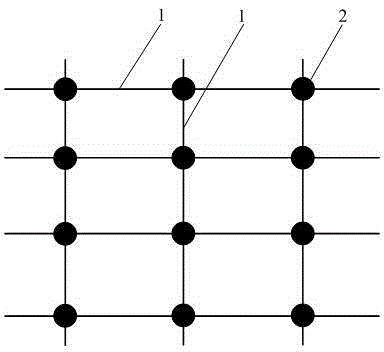

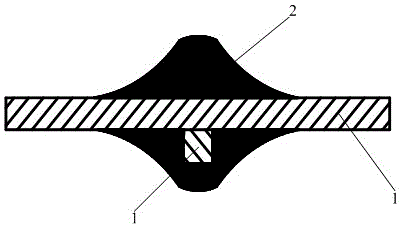

[0024] Such as figure 1 and figure 2 As shown, the high-strength prestressed cast steel wire mesh disclosed by the present invention is based on high-strength steel wire and made by combining the casting process. Compared with the prior art, it not only has better strength, but also has a good The firmness of the product solves the long-standing but unsolvable technical problems in the industry, which has far-reaching significance for the further development of the industry.

[0025] The high-strength prestressed cast steel wire mesh sheet mentioned in this technology is first to select a plurality of high-strength steel wires 1 with a strength above 1570Mpa, and then arrange them in a grid in a criss-cross pattern, and place them in a preset mold; Then melt the engineering plastic into a liquid state, input it into the casting equipment, use the casting equipment to cast the liquid engineering plastic to the intersection point on the grid, so that a casting layer 2 is forme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com