Pile centering method and pile centering device for cast-in-situ piles during construction

A technology of cast-in-place piles and pile cores, which is applied in the direction of foundation structure engineering, sheet pile wall, foundation structure test, etc., can solve problems such as large errors, save manpower, improve engineering construction quality, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

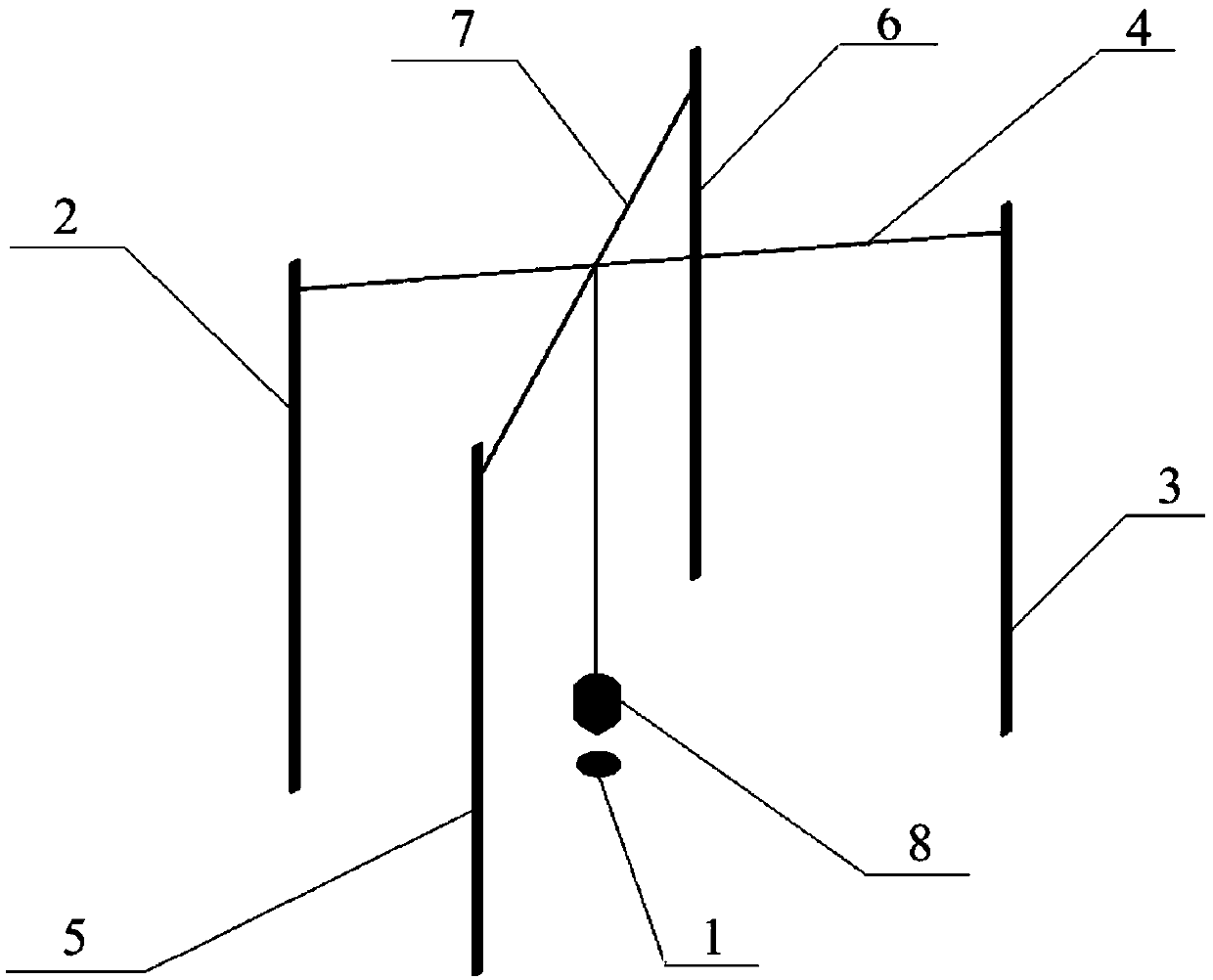

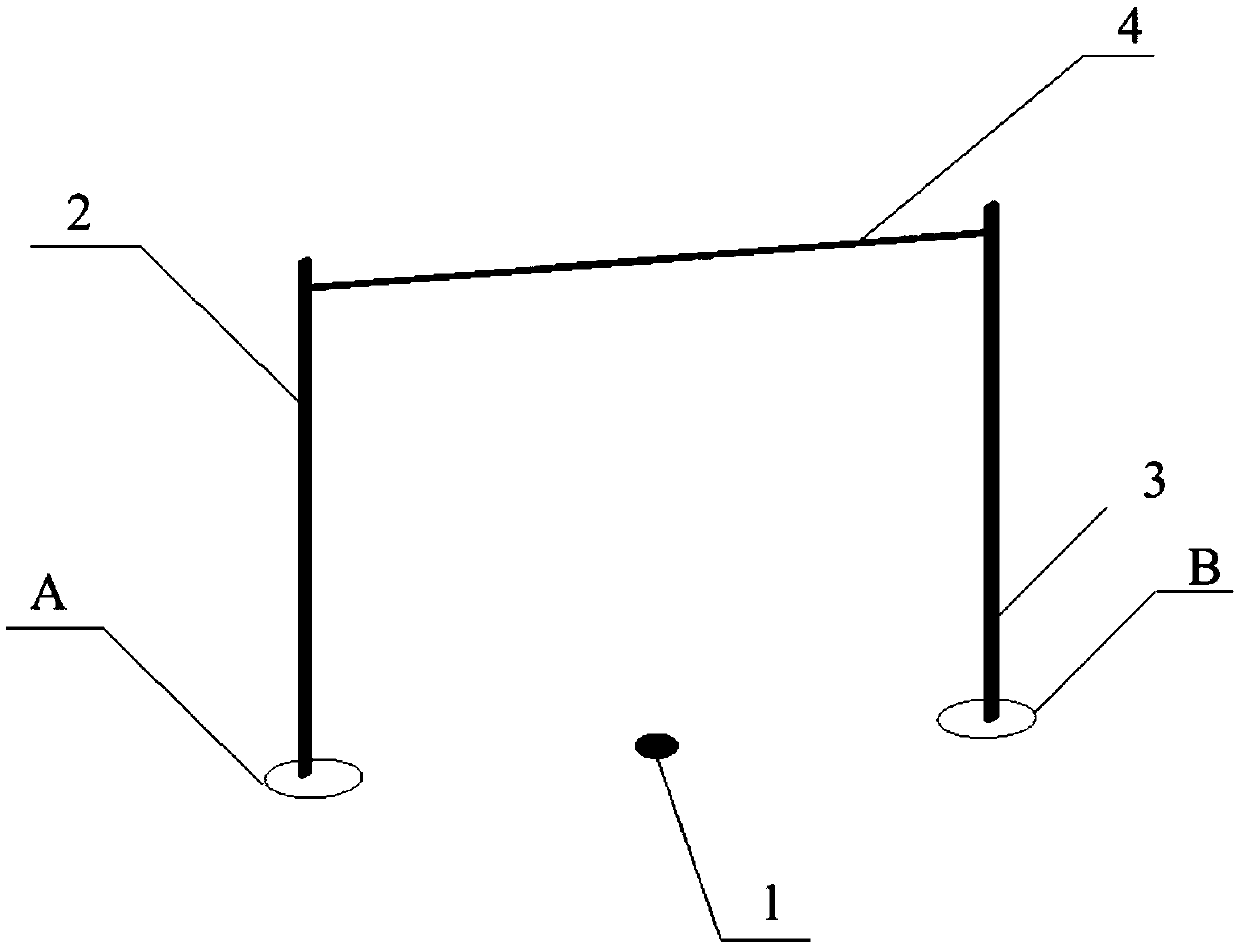

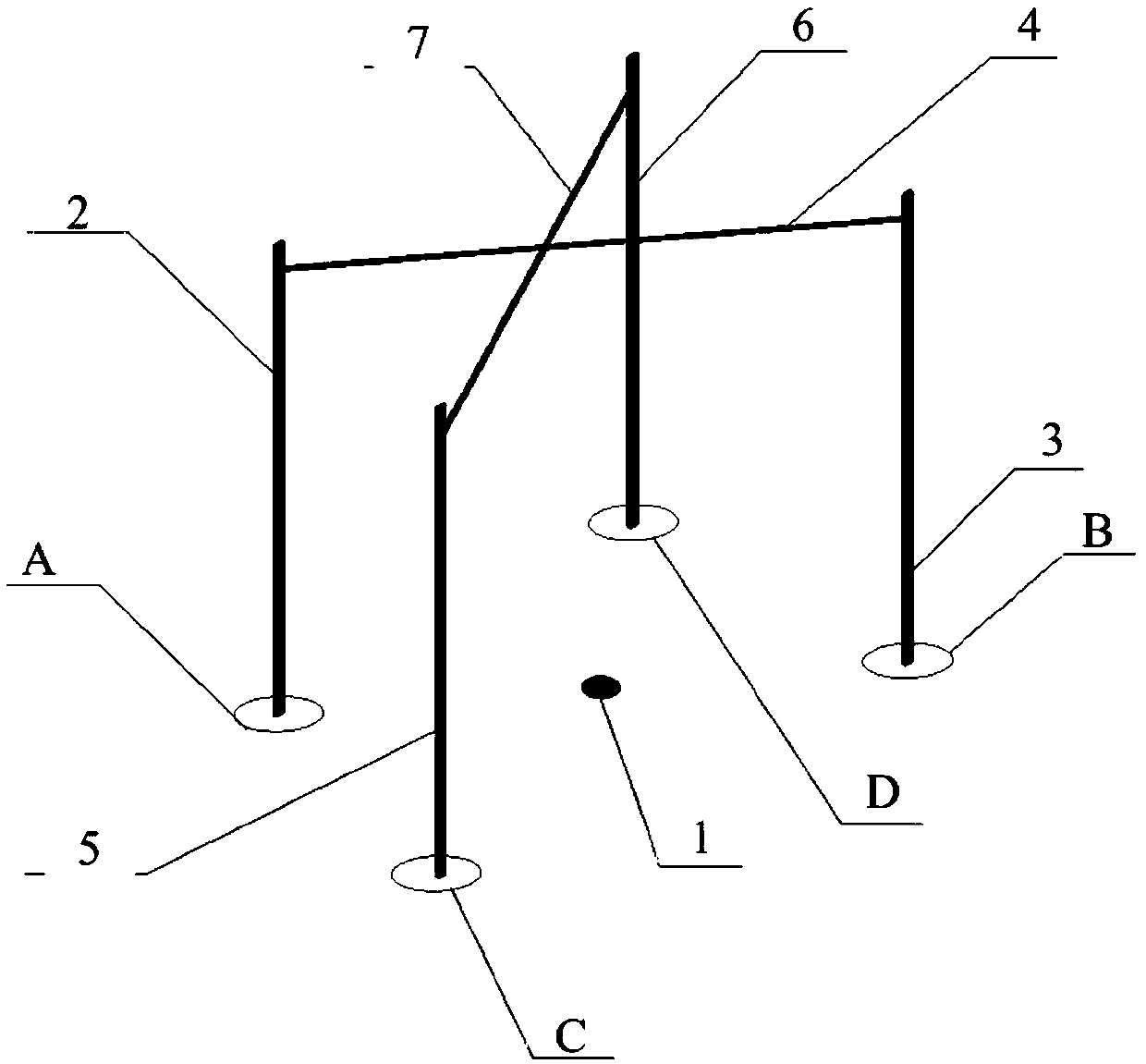

[0036] figure 1 It is the use state diagram of the cast-in-place pile centering device of the present invention, Figure 2 to Figure 7 It is a construction schematic diagram of the pile core centering method during the construction of the cast-in-place pile of the present invention.

[0037] see Figure 1 to Figure 7 , the present invention provides a cast-in-place pile core centering device including a first fixed rod 2, a second fixed rod 3, a first pair of pull wires 4, a third fixed rod 5, a fourth fixed rod 6, and a second pair of pull wires 7 and positioning tool 8.

[0038] The first fixed rod 2 is vertically inserted at the first fixed point A, the second fixed rod 3 is vertically inserted at the second fixed point B, and a first pair of the first fixed rod 2 and the second fixed rod 3 are connected. The stay wire 4, the first fixing point A and the second fixing point B are located on opposite sides of the pile core 1 of the cast-in-place pile.

[0039] The third ...

no. 2 example

[0065] The invention provides a cast-in-place pile core centering device comprising a first fixed rod, a second fixed rod, a first pair of pulling wires, a third fixing rod, a fourth fixing rod, a second pair of pulling wires and a positioning tool.

[0066] The first fixed rod is vertically inserted at the first fixed point, the second fixed rod is vertically inserted at the second fixed point, and a first pair of pull wires are connected between the first fixed rod and the second fixed rod, and the first fixed point and the second fixing points are located on opposite sides of the core of the cast-in-place pile.

[0067] The third fixed rod is vertically inserted at the third fixed point, the fourth fixed rod is vertically inserted at the fourth fixed point, a second pair of pull wires are connected between the third fixed rod and the fourth fixed rod, and the third fixed point and the second fixing points are located on opposite sides of the pile core, and the first pair of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com