Large multi-rib prefabricated aqueduct formwork anti-deformation support device and construction method

The technology of a support device and construction method is applied in the field of anti-deformation support device of large-scale multi-rib prefabricated aqueduct formwork to achieve the effects of reducing construction cost, simplifying support structure and overcoming deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

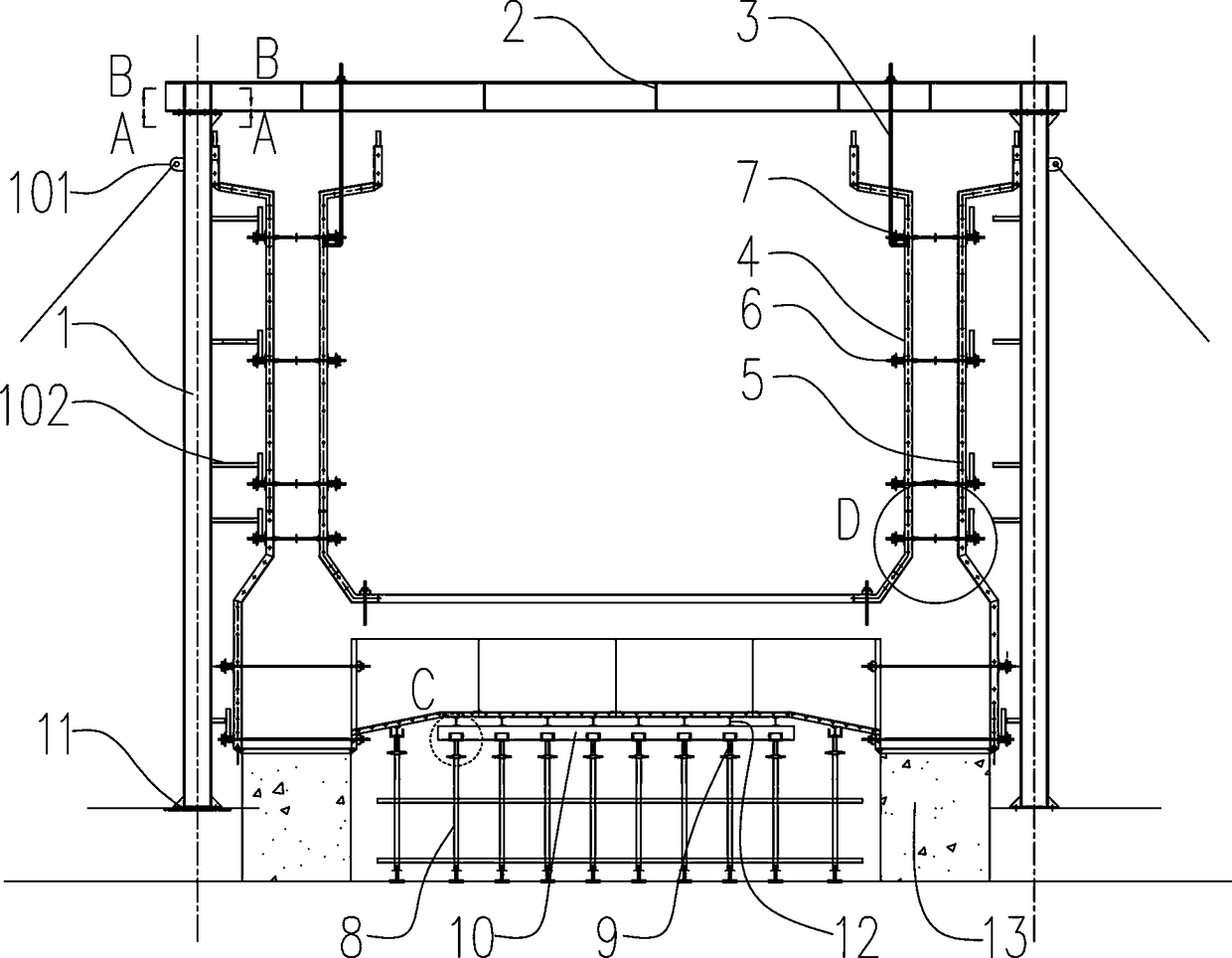

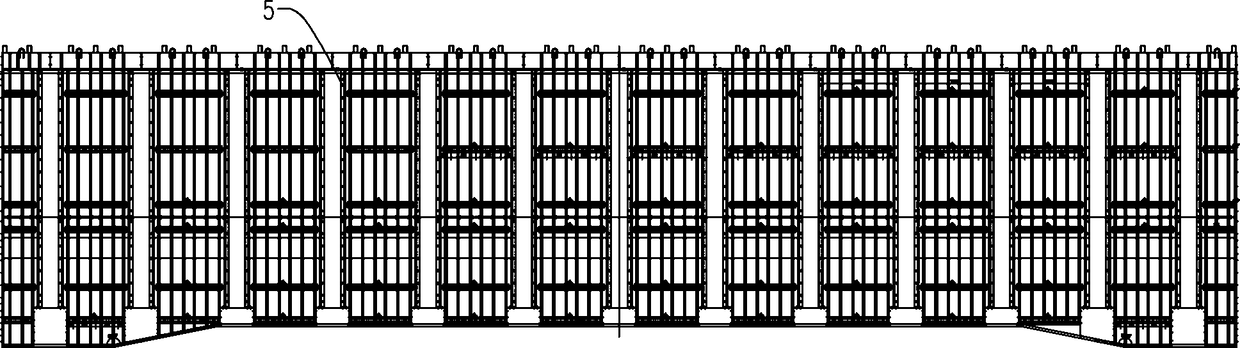

[0046] Such as Figure 1~6 Among them, a large-scale multi-rib prefabricated aqueduct formwork anti-deformation support device includes a plurality of gantry arranged along the outer mold 5, the gantry is fixedly connected with the outer mold 5, and the beam 2 of the gantry is connected to the inner mold through a plurality of inner mold tie rods 3. The mold 4 is fixedly connected, and the bottom of the outer mold 5 is provided with a bottom bracket 8;

[0047] A plurality of embedded bracing screws 6 are arranged between the outer mold 5 and the inner mold 4;

[0048] The top of the inner mold 4 is provided with an inwardly bent bending portion;

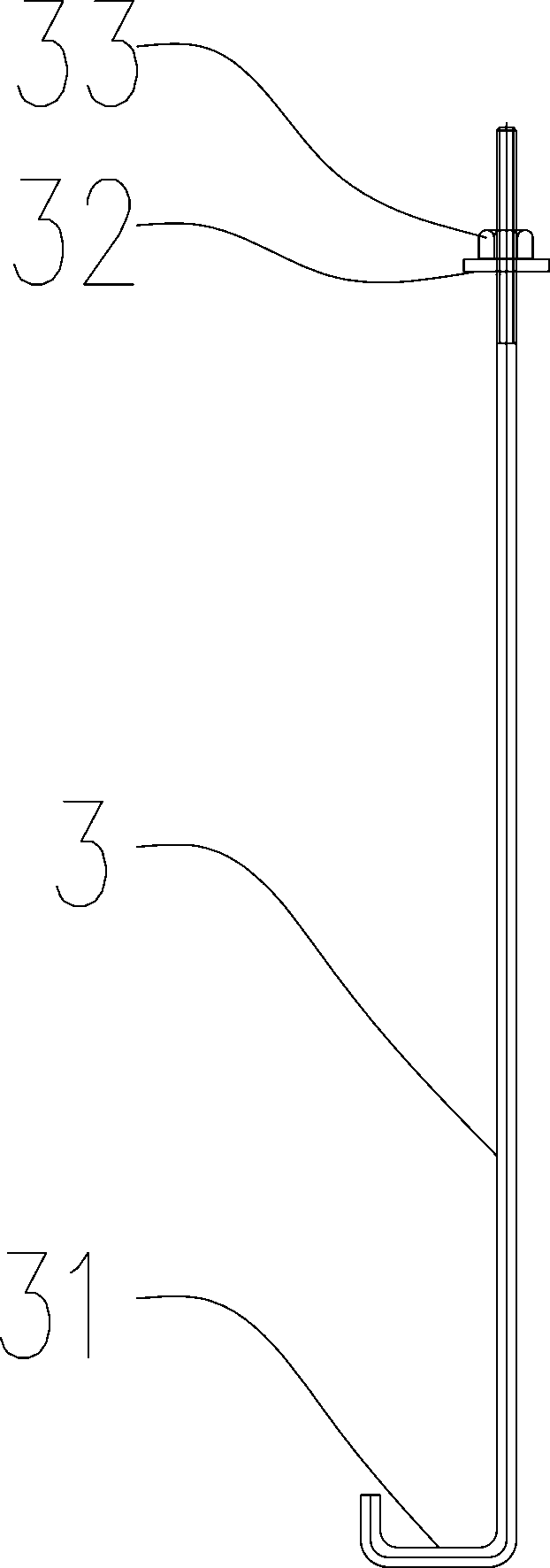

[0049] In the described inner mold tie rod 3, the bottom of the inner mold tie rod 3 is provided with a crotch 31, and the crotch 31 catches the horizontal enclosure 7 inside the inner mold 4, and is fixedly connected with the horizontal enclosure 7, and the inner mold pull rod 3 wears Through the bending part of the inner mold 4 ...

Embodiment 2

[0062] On the basis of embodiment 1, a kind of construction method that adopts above-mentioned large-scale multi-rib prefabricated aqueduct formwork anti-deformation support device comprises the following steps:

[0063] 1. According to the characteristics of the aqueduct structure and formwork structure, carry out structural calculation of formwork force, and design formwork support structure;

[0064] For example, a water conservancy project plans to adopt the tank body prefabrication technology. The cross-sectional size of a single tank is: inner contour 6.5m×5.0m net width×clear height, outer contour 8.7m×7.1~6.6m, bottom plate thickness 0.4m, side wall thickness is 0.5m, the empty tank weighs about 1200t. The tank body is prestressed horizontally, vertically and vertically. The fptk=1860kPa grade steel strand is used for longitudinal and transverse prestressing, and the PS32 finish-rolled threaded prestressing steel bar with a diameter of PSB1080 is used for vertical pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com