Cup grinding wheel variable-positioning-base-circle convex surface workpiece grinding method

A cup-shaped grinding wheel and curved workpiece technology, which is applied in the field of convex curved workpiece grinding, can solve the problems of inability to guarantee the machining accuracy, the influence of machining accuracy, and the wear of the grinding wheel, so as to increase the surface utilization rate, improve the processing efficiency, and avoid the grinding wheel. trimming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] To process k9 glass workpiece, use resin bonded corundum cup-shaped grinding wheel, the diameter of the end face of the grinding wheel is 5cm, and the particle size of the grinding wheel is 120#, and it is processed on a five-axis machining center. The specific processing steps are as follows:

[0050] To process the quadratic surface of the glass workpiece, set its expression as (under the workpiece coordinate system):

[0051]

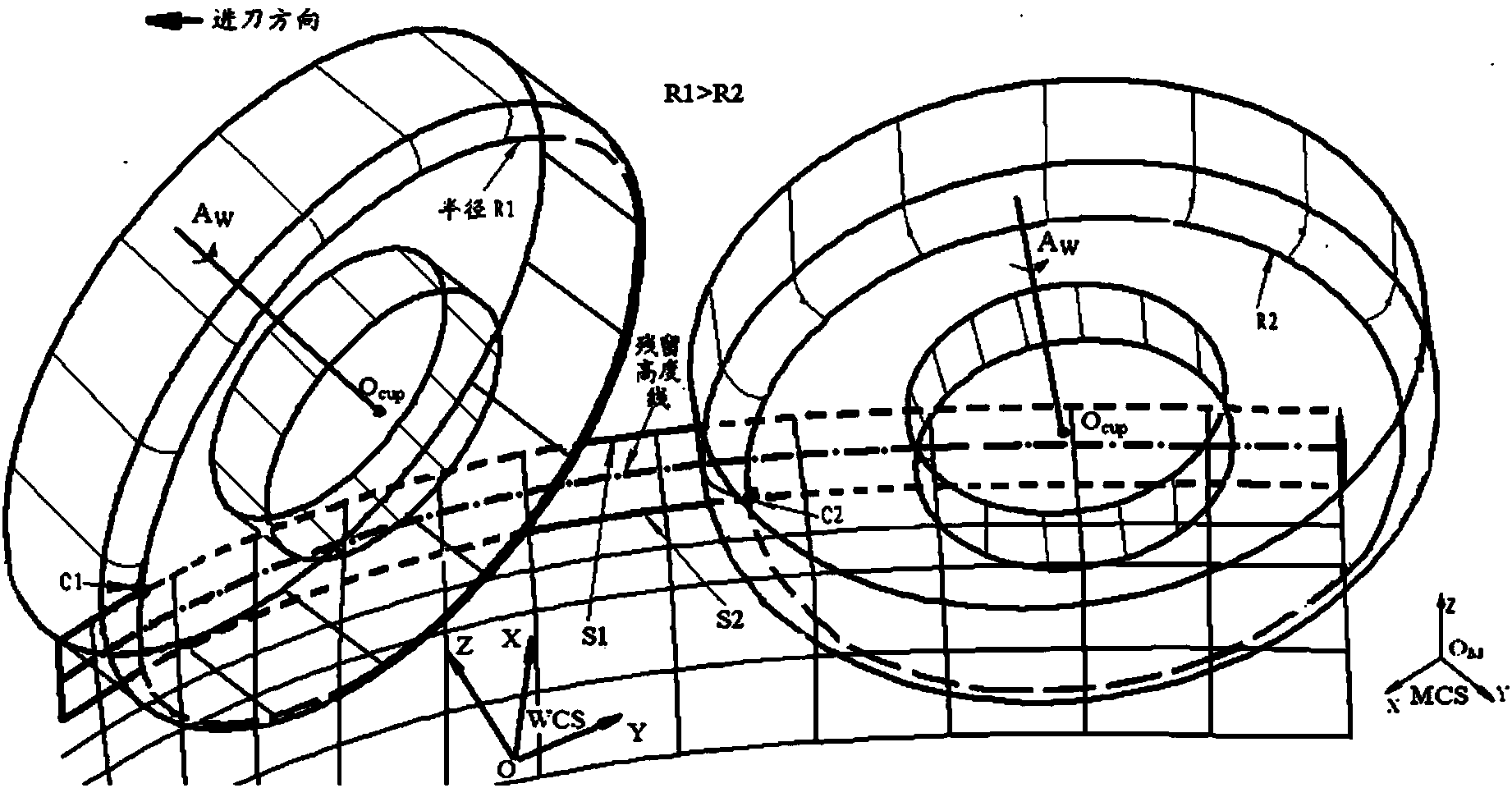

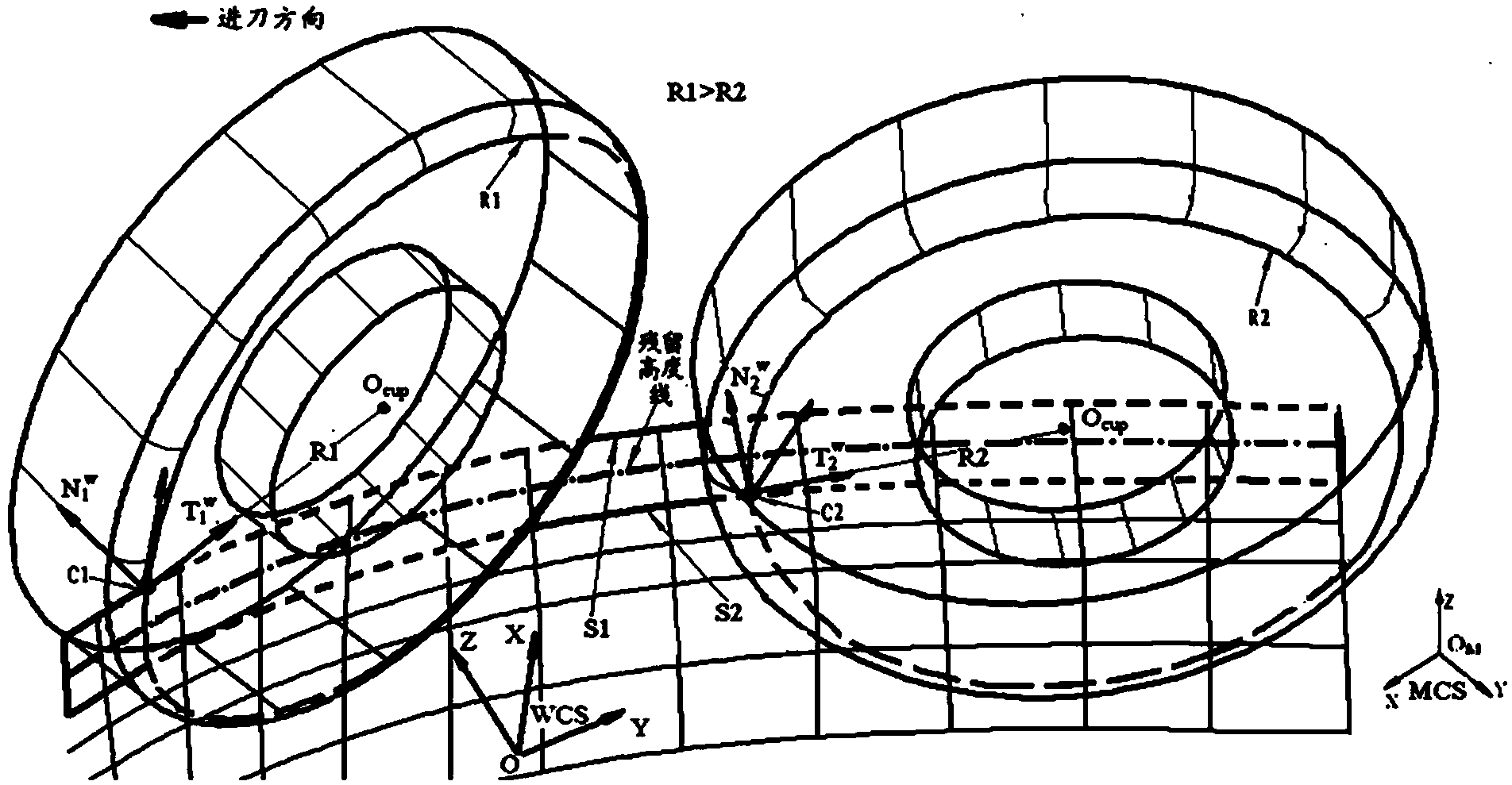

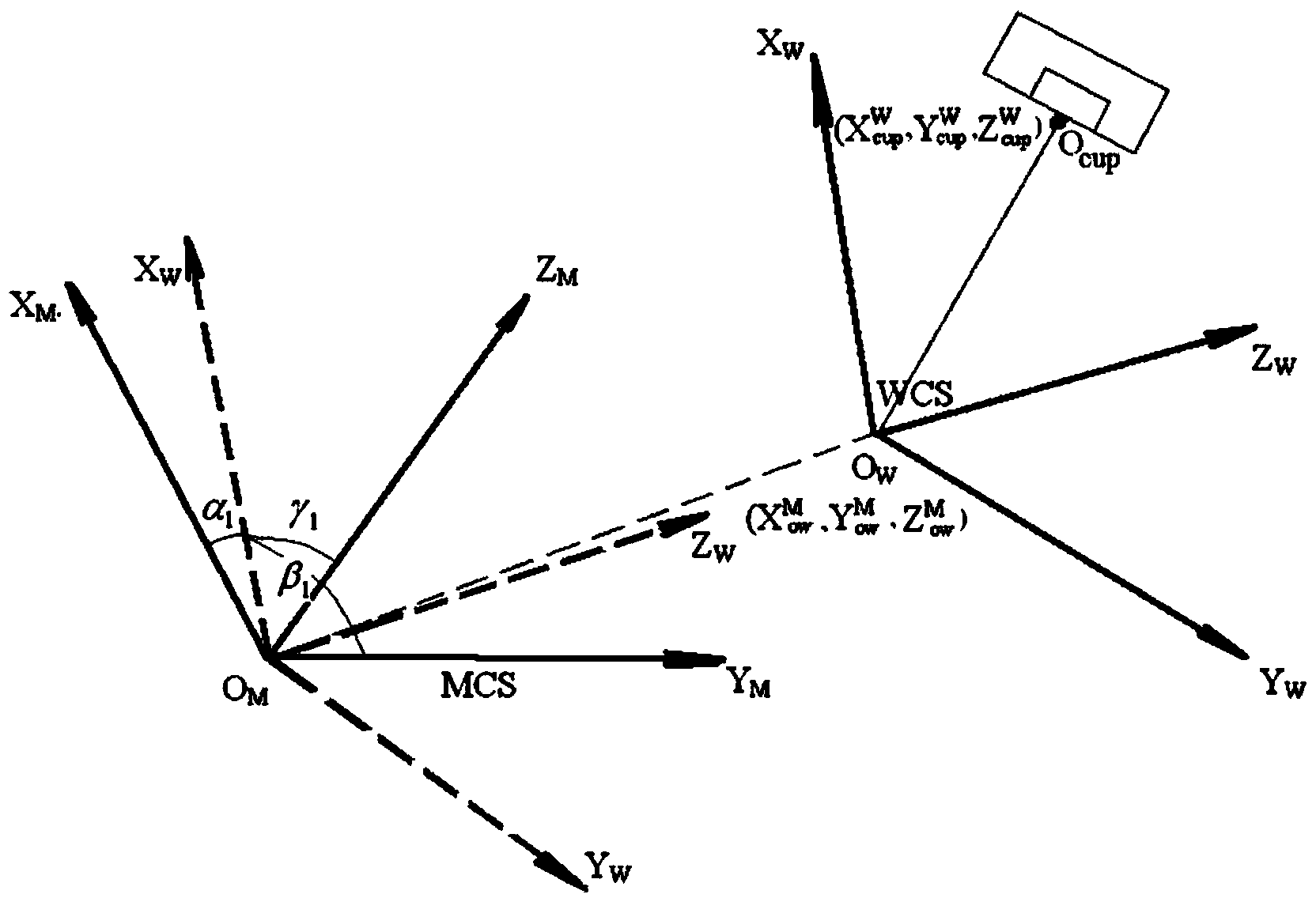

[0052] A cup-shaped grinding wheel installed on a five-axis linkage CNC machine tool is used to process the above-mentioned convex surface workpiece. During the processing, the control system of the CNC machine tool outputs a control signal to the cup-shaped grinding wheel to make the cup-shaped grinding wheel process along the grinding track, and control The system outputs the central point running trajectory control signal to control the movement trajectory of the center point of the end face of the cup-shaped grinding wheel, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com