Method for transferring graphene

A graphene and buffer layer technology, applied in the field of nanoscience and low-dimensional material preparation, can solve the problems of graphene structure damage, interface pollution, surface wrinkles, etc., and achieve the effects of reducing wrinkles, clean upper and lower surfaces, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

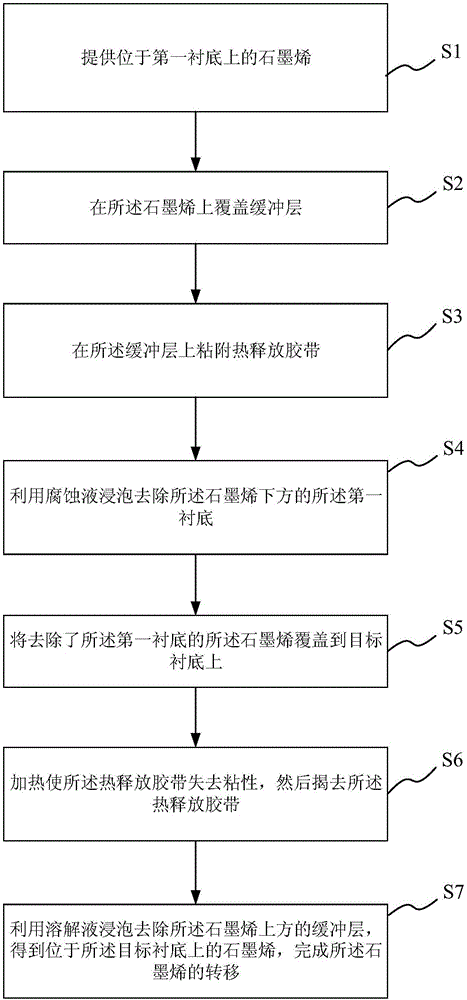

[0083] In this embodiment, a buffer layer is used to transfer the single crystal graphene grown by chemical vapor deposition (CVD) onto the target substrate.

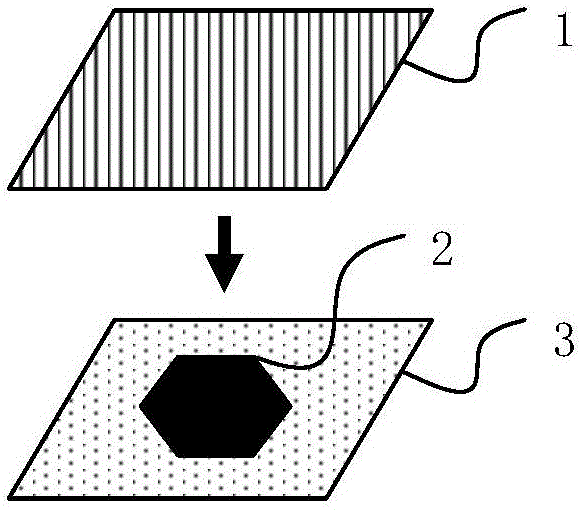

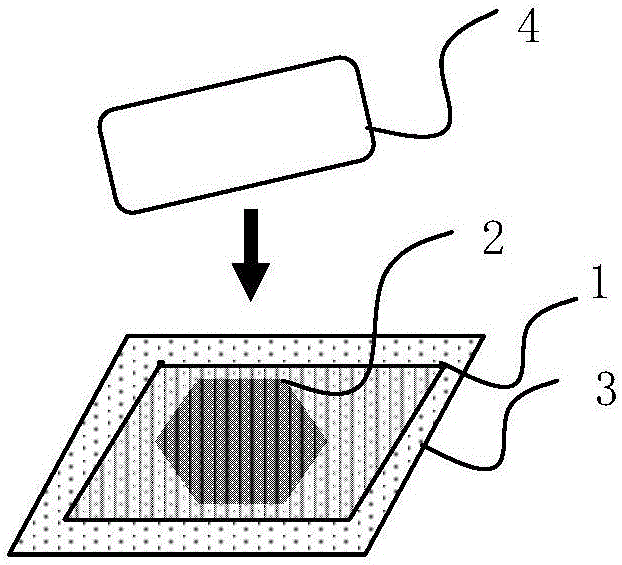

[0084] See first Figure 2 ~ Figure 3 Steps S1 and S2 are executed, and the surface of the graphene 2 on the first substrate 3 is evenly covered with the buffer layer 1 .

[0085] Specifically, graphene 2 is prepared on the first substrate 3 first. As an example, the first substrate 3 is copper foil with a thickness of 25 μm. In other embodiments, the first substrate 3 can also be selected from other catalytic substrates, such as Cu, Ni, Pt, Mo, Pd, Ge, Fe, Co or alloy substrates composed of two or three thereof Wait.

[0086] During the growth process of graphene grown by chemical vapor deposition, the growth temperature is 1000°C~1050°C, the pressure in the chamber is 20Pa~102kPa, the reducing gas is hydrogen, the inert gas is argon, and the flow rate of hydrogen is 5sccm~200sccm, argon The flow rate of the gas is...

Embodiment 2

[0101] This embodiment adopts basically the same technical solution as that of Embodiment 1, except that in Embodiment 1, a buffer layer is used to transfer the discontinuous graphene single crystal grown by CVD to the target substrate. However, in this embodiment, the continuous graphene grown by CVD method is assisted to transfer to the target substrate by using the buffer layer to obtain the continuous graphene film.

[0102] Figure 12 Shown is an optical microscope image of continuous graphene grown by chemical vapor deposition using a buffer layer in this example. Figure 13 Shown is a Raman surface scanning image of continuous graphene grown by chemical vapor deposition using a buffer layer in this example.

Embodiment 3

[0104] The difference between this example and Example 1 is that the buffer layer in Example 1 is changed to methyl methacrylate (MMA), the heating temperature is increased to 70°C, and the heating time is extended to 15 minutes. All the other process parameters are the same as in Example 1.

[0105] Compared with Example 1, as the heat resistance of the buffer layer increases, the heating temperature in the process of curing the buffer layer also increases accordingly. Appropriately increasing the curing temperature of the buffer layer will not have a great impact on the properties of graphene. Figure 14 It shows an optical microscope image of single crystal graphene obtained by changing the buffer layer of this embodiment to methyl methacrylate (MMA) assisted transfer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com