Steel pipe concrete column of I-shaped FRP section

A concrete-filled steel tube column and I-shaped technology, which is applied in the direction of columns, piers, pillars, etc., to achieve the effect of increasing the effective use area, high bearing capacity and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

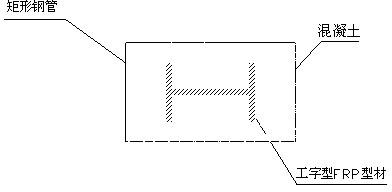

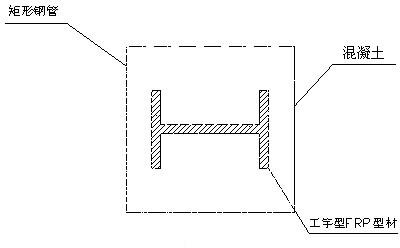

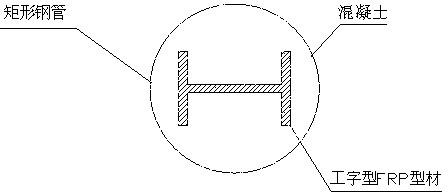

[0017] The concrete-filled steel tube column of the I-shaped FRP profile of the present invention is composed of a rectangular, square or circular steel pipe, an I-shaped FRP profile placed in the steel pipe, and concrete filled between the two, and the characteristic is that the I-shaped FRP profile is Concrete-filled steel pipe column (I-shaped FRP profile-steel pipe-concrete column) is a composite column composed of three different materials: FRP, steel pipe and concrete, that is, I-shaped FRP profile-steel pipe-concrete composite column, of which I-shaped FRP profile - The cross-sectional shape of the steel pipe-concrete column is a rectangular structure, a square structure or a circular structure.

[0018] In the present invention, the steel pipe used in the I-shaped FRP profile-steel pipe-concrete column can be welded by steel plates, and can be rectangular or square or circular, with a built-in I-shaped FRP profile. The configuration of steel pipes is designed according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com