Vacuum insulating material, hot water supplying device using the same and electric drive type hot water device

A technology of vacuum heat insulation materials and core materials, which is applied in heat exchange equipment, mechanical equipment, special materials for cooking utensils, etc., can solve the problems of poor airtightness and easy drop in airtightness, and achieve the purpose of inhibiting the entry of gas and moisture, High airtightness and the effect of suppressing the deterioration of thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

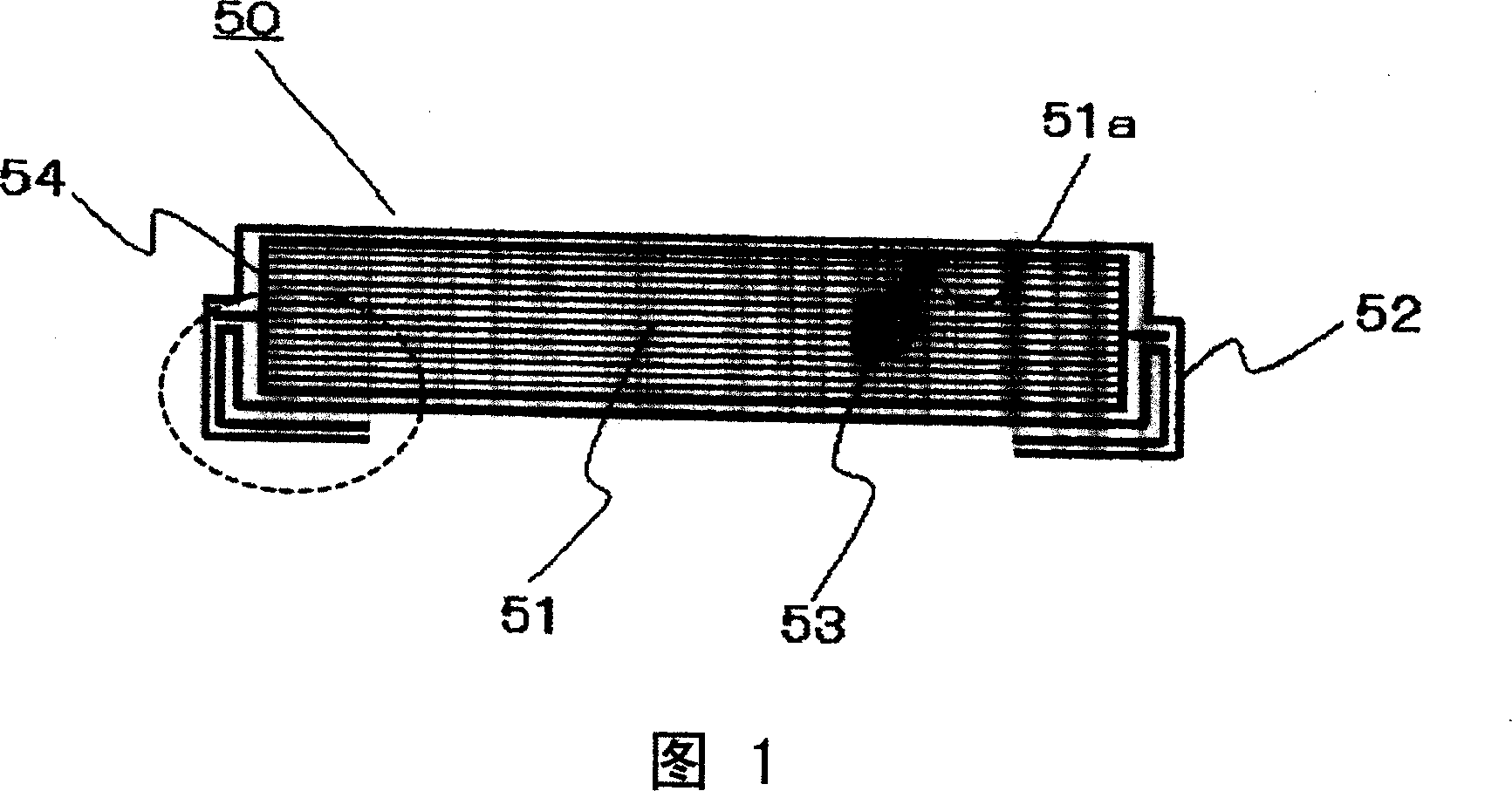

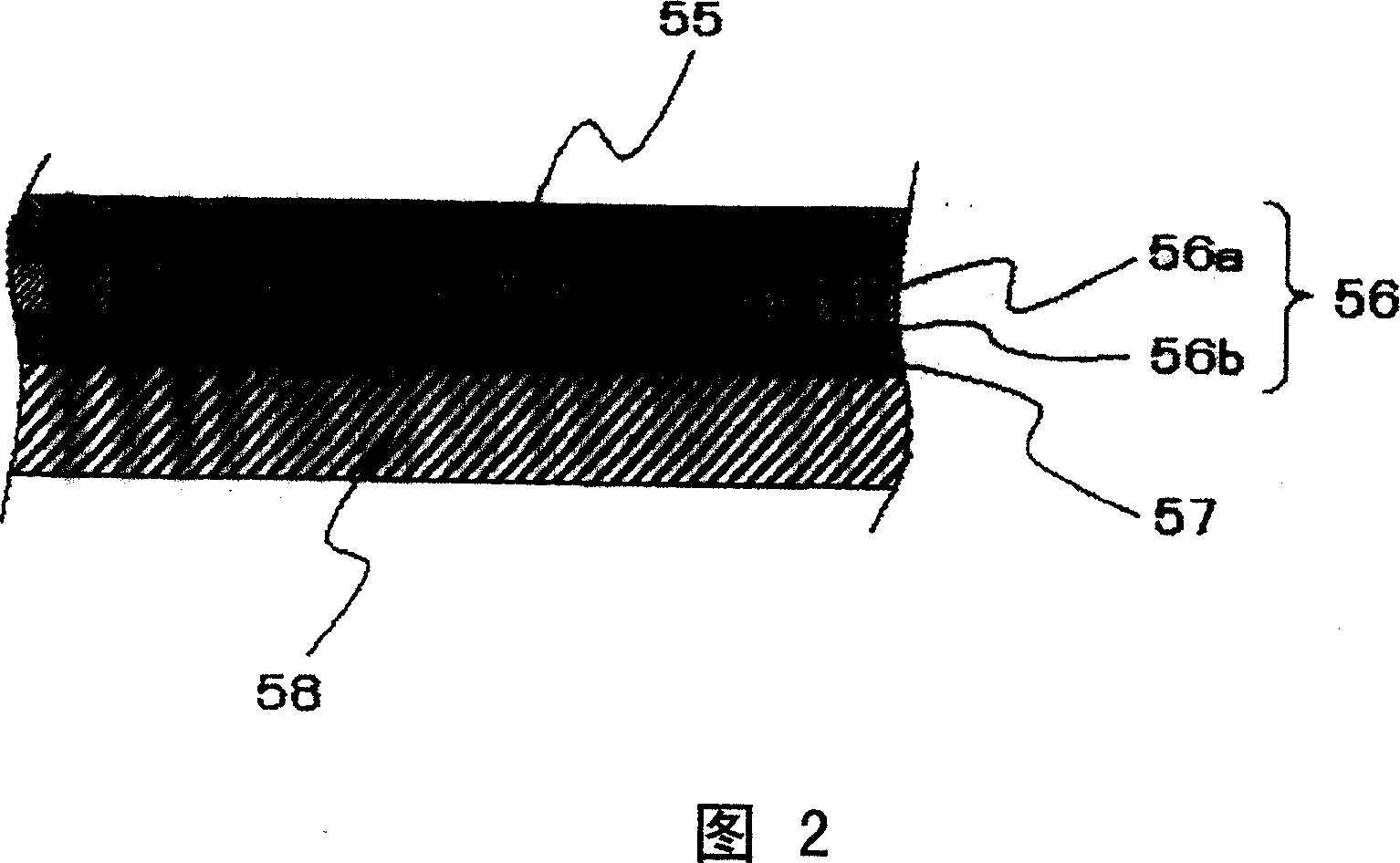

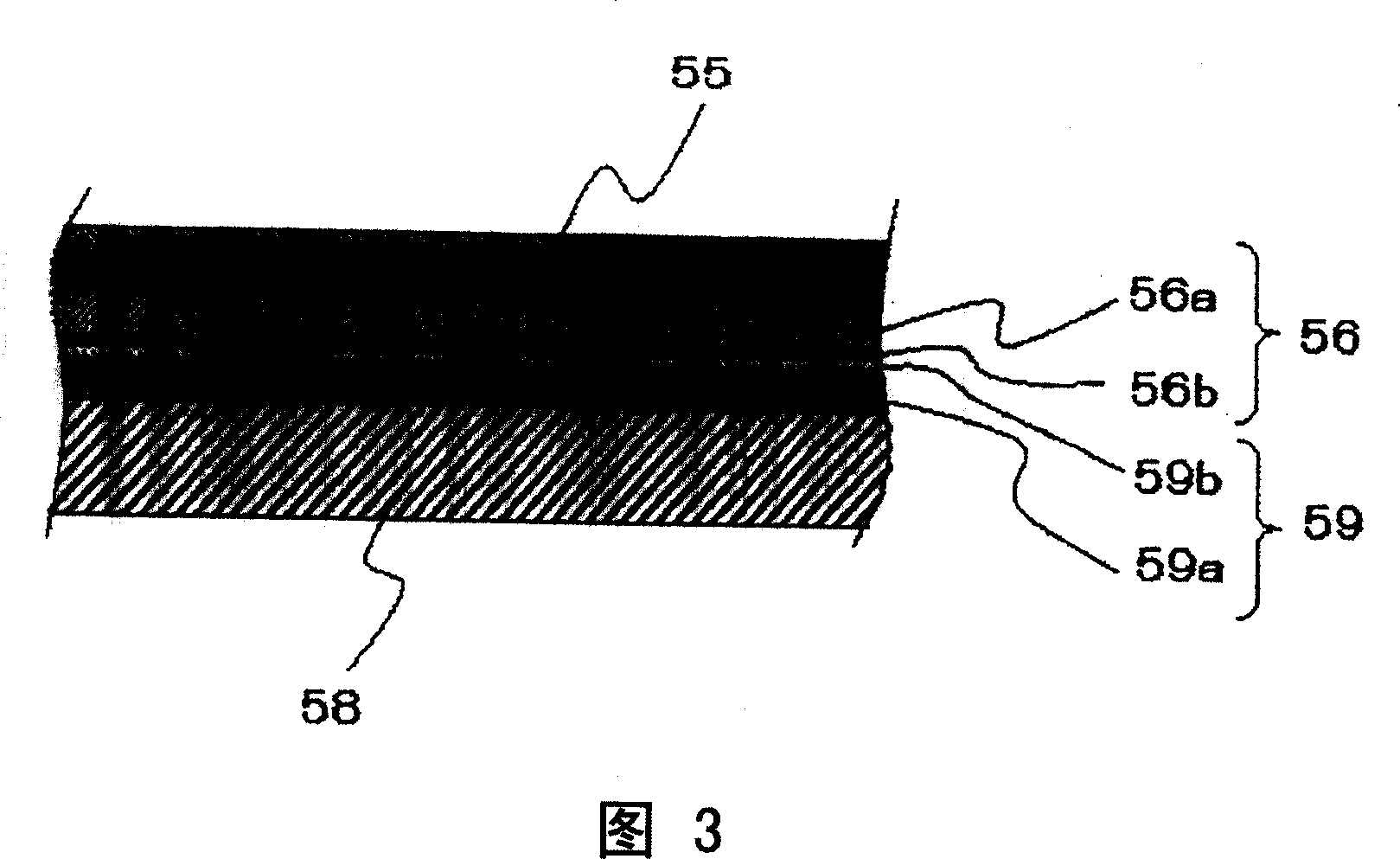

[0061] The first example is an example in which the film structure of the wrapping material 52 is formed as shown in FIG. 2 in the vacuum heat insulating material 50 shown in FIG. 1 . A binder-free glass wool laminate having an average fiber diameter of 4 μm was used as the core material 51 .

[0062] The specific structure of the covering material 52 of Example 1 is shown. Polyamide film (ONY) is used as the outermost surface protection layer 55, and polyethylene terephthalate (PET) is used as the resin film 56a for the first airtight layer 56 provided inside the surface protection layer 55. , and vapor-deposit aluminum with a thickness of 400-500 Ȧ as the metal vapor-deposition layer 56b. In addition, the second airtight layer 57 is an iron-mixed aluminum foil (AL) having a thickness of 6 μm. In addition, the aluminum vapor-deposited surface of the first airtight layer 56 and the aluminum foil of the second airtight layer 57 are bonded to face each other. An adhesive havi...

no. 2 Embodiment

[0077] In the second example, the vacuum heat insulating material 50 was produced under the same conditions as in the first example except that the adsorbent 53 was made of calcium oxide. Calcium oxide is a hydrophilic chemical adsorbent that absorbs water and becomes calcium hydroxide.

[0078] When the thermal conductivity indicating the thermal insulation performance of the vacuum heat insulating material 50 obtained in this way was measured in the same manner as in Example 1, the initial value was 0.0021 (W / m·K), which corresponds to the thermal conductivity after 5 years in this example. The rate value was 0.0068 (W / m·K), and it was confirmed that sufficient thermal insulation performance was maintained. In addition, the appearance of the vacuum heat insulating material 50 does not change in particular.

Embodiment 3

[0080] In the third embodiment, except that the hydrophobic synthetic zeolite with an average pore diameter of 6 Ȧ or more and the hydrophilic synthetic zeolite with an average pore diameter of 9 Ȧ are used together as the adsorbent 53, vacuum insulation is produced under the same conditions as in Example 1. Thermal Material 50. Hydrophobic synthetic zeolites are physical adsorbents, SiO 2 / Al 2 o 3 The ratio is 20 or more, and it is a high silica zeolite which is non-combustible.

[0081] When the thermal conductivity indicating the heat insulating performance of the thus obtained vacuum heat insulating material 50 was measured in the same manner as in Example 1, the initial value was 0.0022 (W / m·K). The rate value was 0.0059 (W / m·K). In addition, the appearance of the vacuum heat insulating material 50 does not change in particular.

[0082] In Example 3, by using a hydrophilic adsorbent and a hydrophobic adsorbent in combination, while the hydrophilic adsorbent prefere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com