Vacuum insulating material, hot water supplying device using the same and electric drive type hot water device

A technology of vacuum insulation materials and core materials, which is applied in heat exchange equipment, mechanical equipment, special materials for cooking utensils, etc., can solve the problems of poor air tightness and decreased air tightness, etc. , the effect of inhibiting the entry of gas and moisture

Inactive Publication Date: 2010-09-08

HITACHI APPLIANCES INC

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

On the high temperature side, the effect of small holes in the aluminum foil is taken into consideration. On the low temperature side, the vapor-deposited aluminum layer is less airtight than the original aluminum foil, and the airtightness tends to drop even in either structure.

In addition, although organic gas components are generated from adhesives, solvents, etc. from the laminated portion of the outer cover material 12 due to the influence of the high temperature side, these are not taken into consideration.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

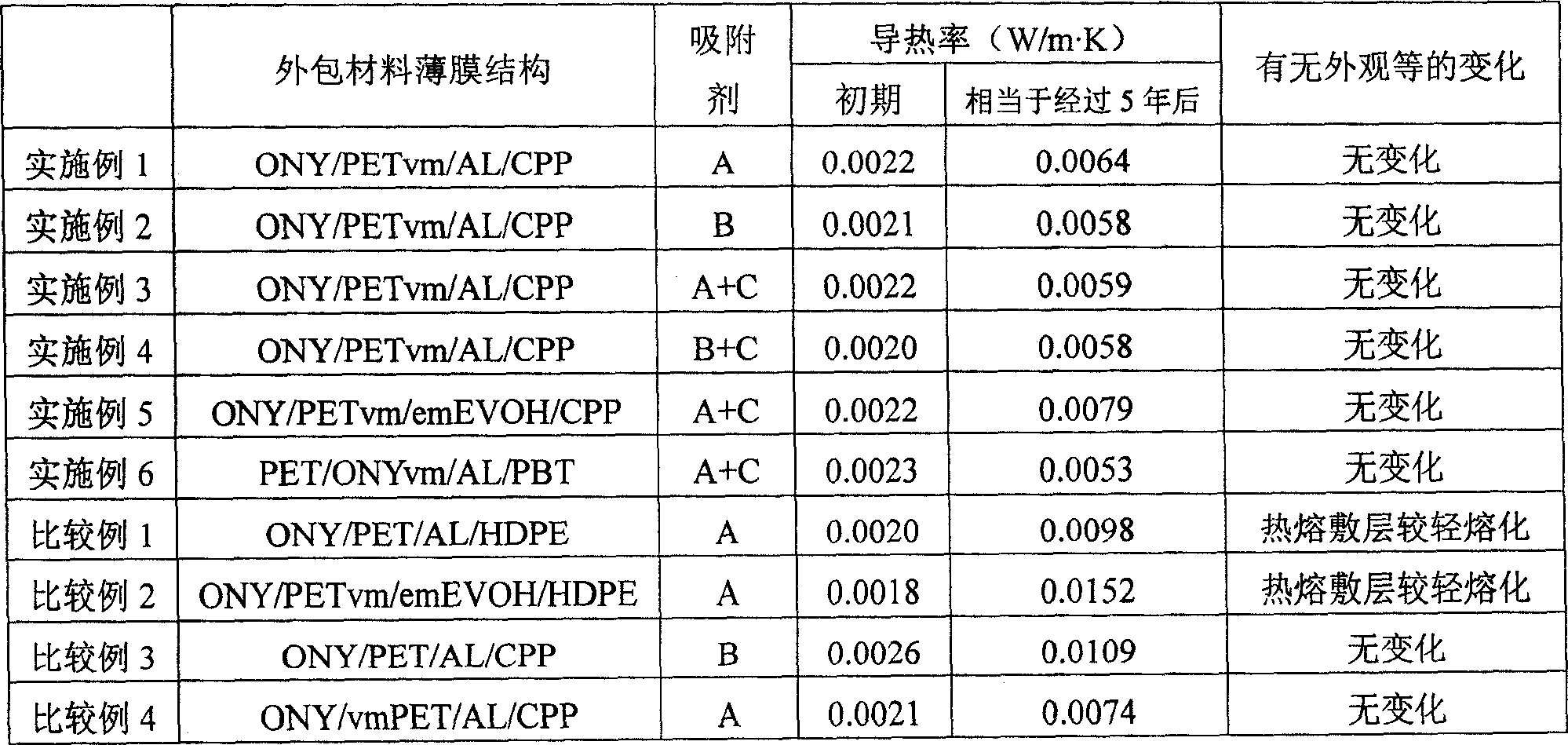

Embodiment 1

no. 2 Embodiment

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Login to View More

Abstract

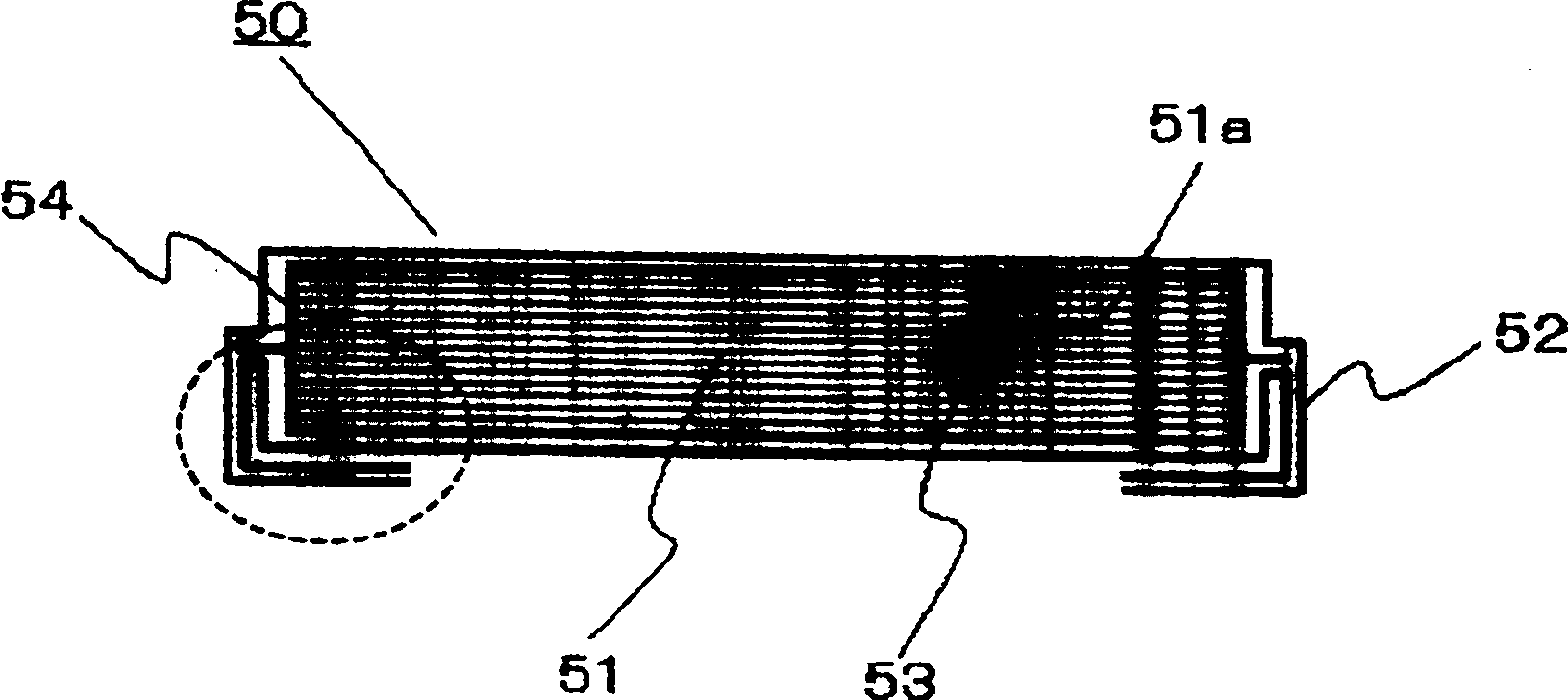

The present invention provides a vacuum heat insulation material capable of maintaining high heat insulation capacity even in high temperature circumstance, and provides a hot water supply device having high heat insulation capacity. In the vacuum heat insulation material comprising core material (51) composing of inorganic fiber polymer, a housing material (52) having surface protection layer and aerospace sealing layer and heat melting coating layer, and sorbent (53) absorbing the moisture and air component of core material (51) and the housing material (52), the heat insulation capacity can be maintained in long time in condition of high temperature by laminating the aerospace sealing layer of the housing material (52) with a first aerospace sealing layer and the second aerospace sealing layer in terms of opposite metal surface of at least tow layers of metal layer, and using resin film with melting point more than 150 DEG C as heat melting coating layer.

Description

technical field The present invention relates to a vacuum heat insulating material, a hot water supply device using the vacuum heat insulating material, and an electric hot water device. Background technique In recent years, from the viewpoint of global warming, the need to reduce power consumption has been demanded in household electrical appliances. For example, a refrigerator is a product that consumes electricity among home appliances, and reducing the electricity consumption of the refrigerator has become an indispensable situation as a countermeasure against global warming. Under such circumstances, refrigerators employing vacuum insulation materials have been commercialized to suppress unnecessary heat exchange with the outside and remarkably improve heat insulation efficiency. As the main application fields of existing vacuum insulation materials, refrigerators are the first, and products with lower temperature ranges such as ultra-low temperature freezers, transpo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F16L59/02F16L59/06A47J27/21A47J36/02

CPCB66C13/14B66C19/00

Inventor 越后屋恒荒木邦成福田克美鹤贺俊光嘉本大五郎

Owner HITACHI APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com