Preparation method for high performance water reducer made from high water reducing solid polycarboxylic acid

A water-reducing type, polycarboxylic acid technology, applied in the field of concrete admixtures, can solve the problems of inability to meet high water reduction and low dosage, and achieve the effects of stable storage, high conversion rate, and improved dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

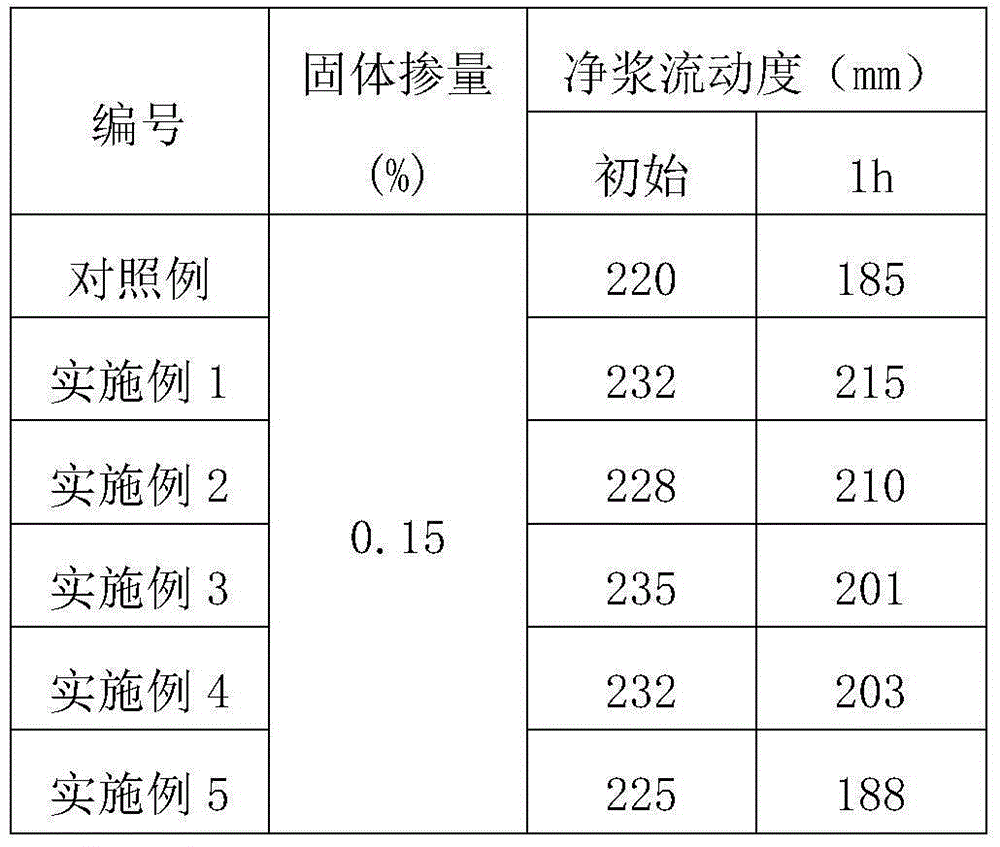

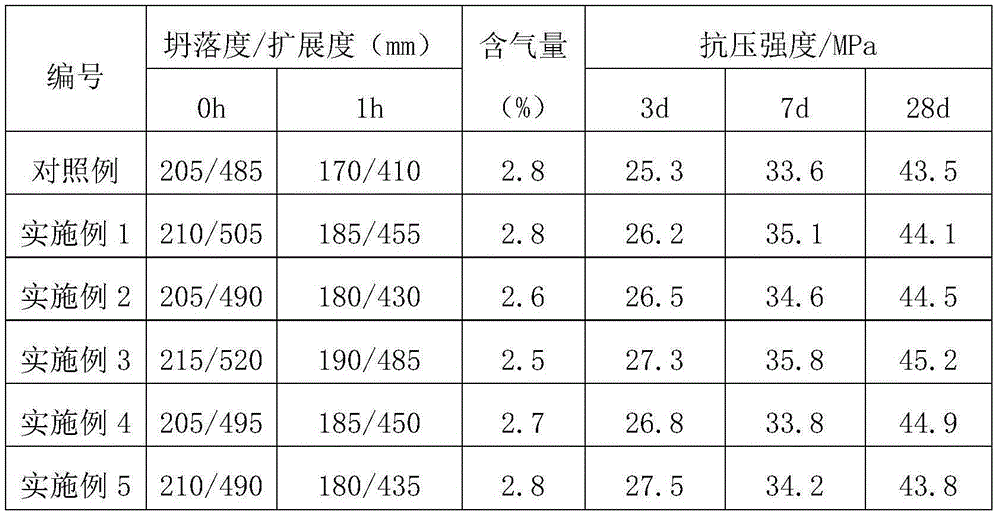

Examples

Embodiment 1

[0020] Put 100g of methallyl alcohol polyoxyethylene ether (molecular weight of 2400) and 25g of methallyl alcohol polyoxyethylene ether (molecular weight of 1400) into the kettle, heat to 55°C and melt, then add 0.5g of azobis Isobutyronitrile, then start to drop a mixture of 13g of acrylic acid, 1g of acrylamide and 1g of thioglycolic acid, the dropwise addition time is 2, after the dropwise addition is completed, keep warm at 55°C for 3h, after the reaction is completed, add 1g of sodium hydroxide to adjust the pH to 5.5 , after cooling, it is ground into solid particles.

Embodiment 2

[0022] Put 100g of isobutenyl alcohol polyoxyethylene ether (molecular weight: 2900) and 20g of methallyl alcohol polyoxyethylene ether (molecular weight: 1200) in a kettle, heat to 65°C and melt, then add 0.6g of azobisisoheptanonitrile , and then began to drop a mixture of 15g of acrylic acid, 1.3g of methylolacrylamide and 1.2g of mercaptopropionic acid. The dropwise addition time was 3 hours. The pH is adjusted to 5, and after cooling, it is ground into solid particles.

Embodiment 3

[0024] Put 400g prenyl alcohol polyoxyethylene ether (molecular weight: 3500) and 60g methoxypolyethylene glycol monomethyl ether acrylate (molecular weight: 800) into the kettle, after heating to 60°C for melting, add 3.2g supernatant Ammonium sulfate, then began to drop a mixture of 72g of methacrylic acid, 6g of isopropylacrylamide and 5.2g of sodium hypophosphite, and the time for adding was 5. 5.2g of magnesium hydroxide was used to adjust the pH to 5.3, and after cooling, it was ground into solid particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com