Production method of vacuum glass

A vacuum glass and production method technology, applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve the problems of adding large vacuum equipment, affecting the performance of vacuum glass, opacity of metal materials, etc., and achieve long-term stable high Vacuum degree, conducive to popularization and use, and good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

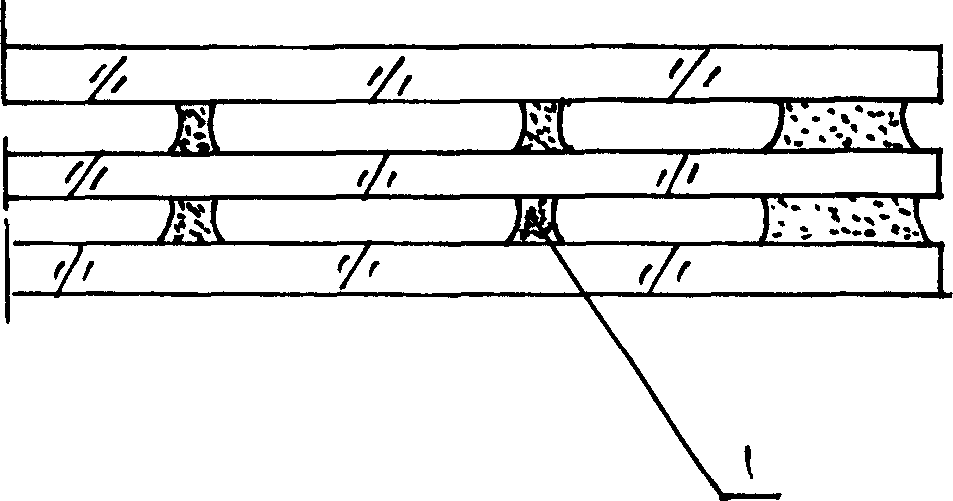

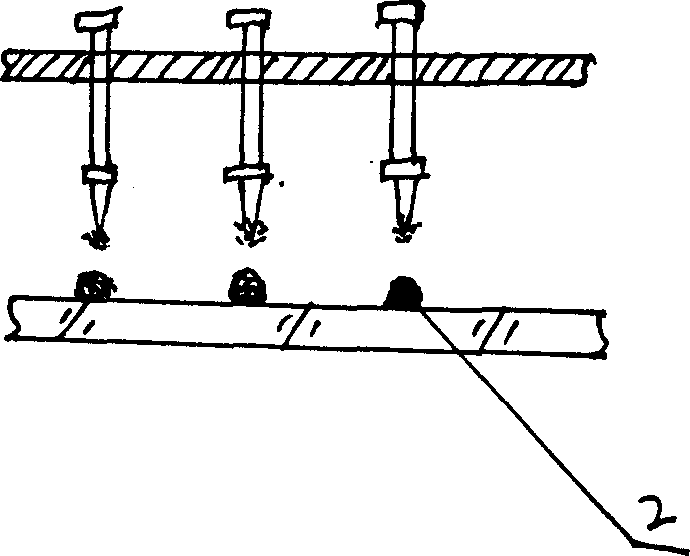

[0036] Example 1. refer to figure 1 , figure 2 . A method for producing vacuum glass. Put low-melting glass frit paste on one of the glasses to form a glass frit pile 2, and apply a closed strip along the periphery of the glass surface on which the frit pile 2 is placed. Low-melting point glass powder paste strips, with several fortified adhesive supports between the upper and lower glass pieces, put the pieces together and heat-melt them in the sintering furnace. While heat-melting and sealing the edges, the glass powder pile 2 is melted to form a glass The support 1 is vacuum-sealed to obtain vacuum glass.

Embodiment 2

[0037] Example 2. refer to figure 1 , figure 2 . A method for producing vacuum glass, in which low-melting point glass frit paste is placed on one piece of glass by dripping to form a pile of glass frit 2, and the glass surface on which the frit pile 2 is placed is placed along the periphery of the glass surface. Apply a closed strip of low-melting glass powder paste, and set several fortified adhesive supports between the upper and lower sheets of glass. After the sheets are combined, they are placed in a sintering furnace for heat fusion. 2 The glass support 1 is formed after melting, and the vacuum glass is obtained after vacuum sealing. The vacuuming method is to drill a straight hole for exhaust on the upper piece of glass, place a non-evaporable getter in the hole, then insert the exhaust glass tube, and coat the glass surface around the glass tube with low The melting point glass powder paste is melted in the sintering furnace, then heat-preserved, cooled to the ex...

Embodiment 3

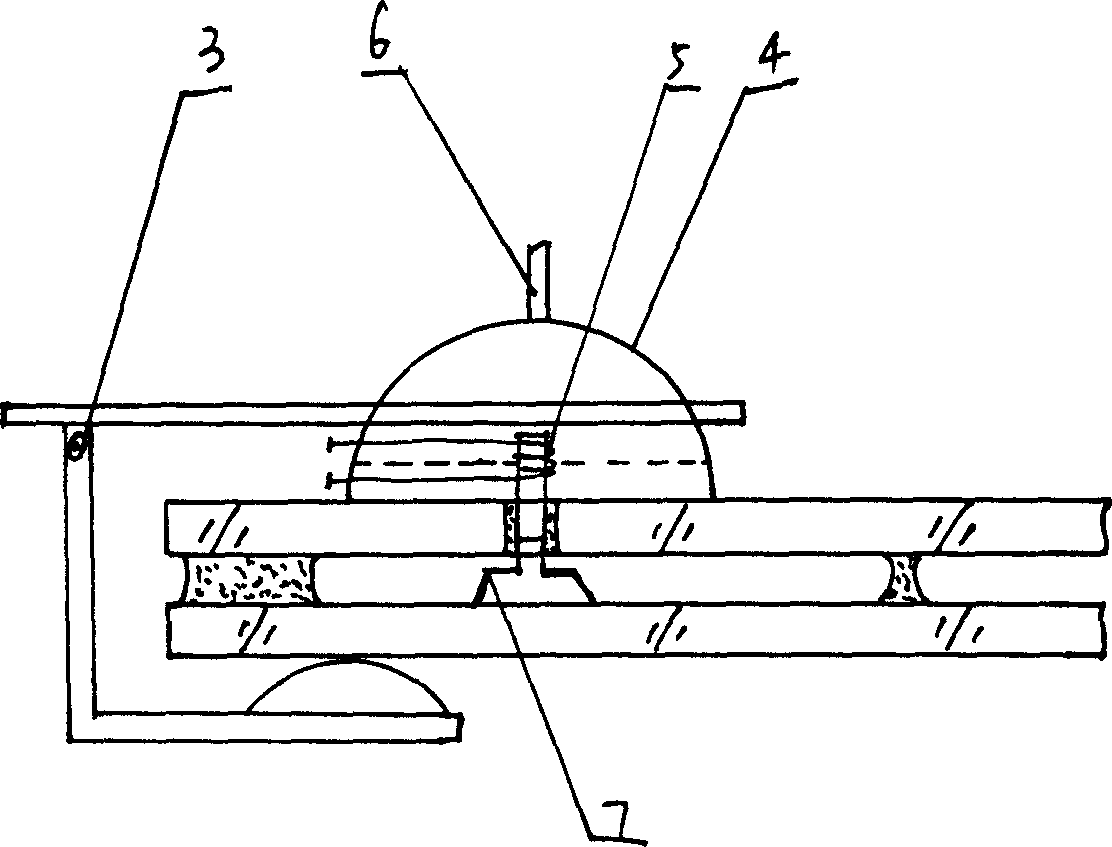

[0038] Example 3. refer to figure 1 , figure 2 , image 3 . A method for producing vacuum glass, in which a low-melting point glass frit paste is placed on one of the glasses by coating to form a glass frit pile 2, and the glass frit pile 2 is placed along the periphery of the glass surface. Apply a closed strip of low-melting glass powder paste, and set several fortified adhesive supports between the upper and lower sheets of glass. After the sheets are combined, they are placed in a sintering furnace for heat fusion. 2 The glass support 1 is formed after melting, and the vacuum glass is obtained after vacuum sealing. The vacuuming method is to drill a straight hole for exhaust on the upper piece of glass, place a non-evaporable getter in the hole, then insert the exhaust glass tube, and coat the glass surface around the glass tube with low The melting point glass powder paste is melted in the sintering furnace, then heat-preserved, cooled to the exhaust temperature, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com