Rapid casting part cooling device for casting

A technology for rapid cooling and casting, applied in the field of casting, can solve the problems of low degree of automation, affecting the cooling efficiency of castings, etc., to achieve the effect of good cooling effect, convenient cooling work, and improving the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

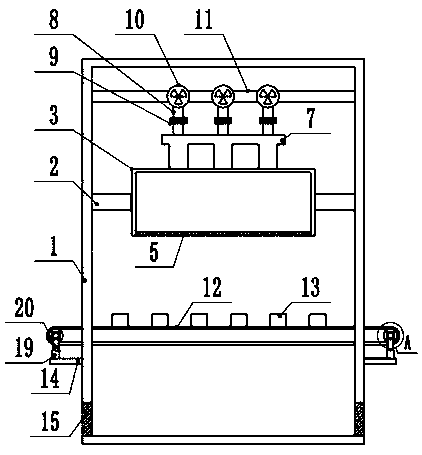

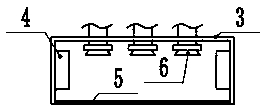

[0021] see Figure 1-3 , a fast cooling device for castings, comprising a device box 1, a fixing frame 2 is fixedly connected above the inner walls of the left and right sides of the device box 1, and a cooling box 3 is fixedly installed inside the middle of the fixing frame 2, and the left and right sides of the cooling box 3 A condenser 4 is fixedly installed on the inner wall of the side, and a breathable plate 5 is fixedly connected to the box below the cooling box 3, and the breathable plate 5 is located directly above the conveyor belt 12, and an exhaust port is provided under the box body on the left and right sides of the device box 1 15.

[0022] Specifically, a connecting pipeline 7 is fixedly connected to the middle of the box above the cooling box 3, and the lower end of the connecting pipeline 7 is fixedly installed with an air nozzle 6, and the upper surface of the connecting pipeline 7 is fixedly connected to a fan pipe 8. The upper end of the fan duct 8 is con...

Embodiment 2

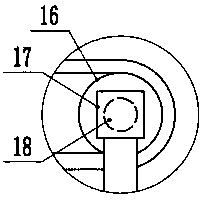

[0024] see Figure 4 The difference between the second embodiment and the first embodiment is that a chute 21 is provided in the middle of the top of the support base 19, a spring 22 is fixedly connected to the lower surface of the chute 21, and a fixed rod 20 is fixedly connected to the upper end of the spring 22, and the fixed rod 20 It is connected with the surface of the left and right sides of the chute 21 in a contact manner. The conveyor belt 12 is prone to shaking during the transmission process. The spring 22 is installed inside the chute 21 to make the conveyor belt 12 more stable during the transmission process and ensure the safety of the conveyor belt 12. run.

[0025] This fast cooling device for castings is equipped with a condenser 4 in the cooling box 3, so that cold air is generated in the cooling box 3, and the air nozzle 6 is blown by the fan 10, and the cold air is blown to the surface of the casting 13, so that The casting 13 is cooled quickly, the cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com