Method for integrally casting and molding single crystal part based on gel-casting with seed crystal block embedded structure spiral crystal selector

A technology of spiral crystal separator and gel injection molding, which is applied in the directions of casting mold components, casting molding equipment, chemical instruments and methods, etc., can solve the problems of miscellaneous crystals and poor controllability of secondary dendrite orientation, and achieve a broad The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

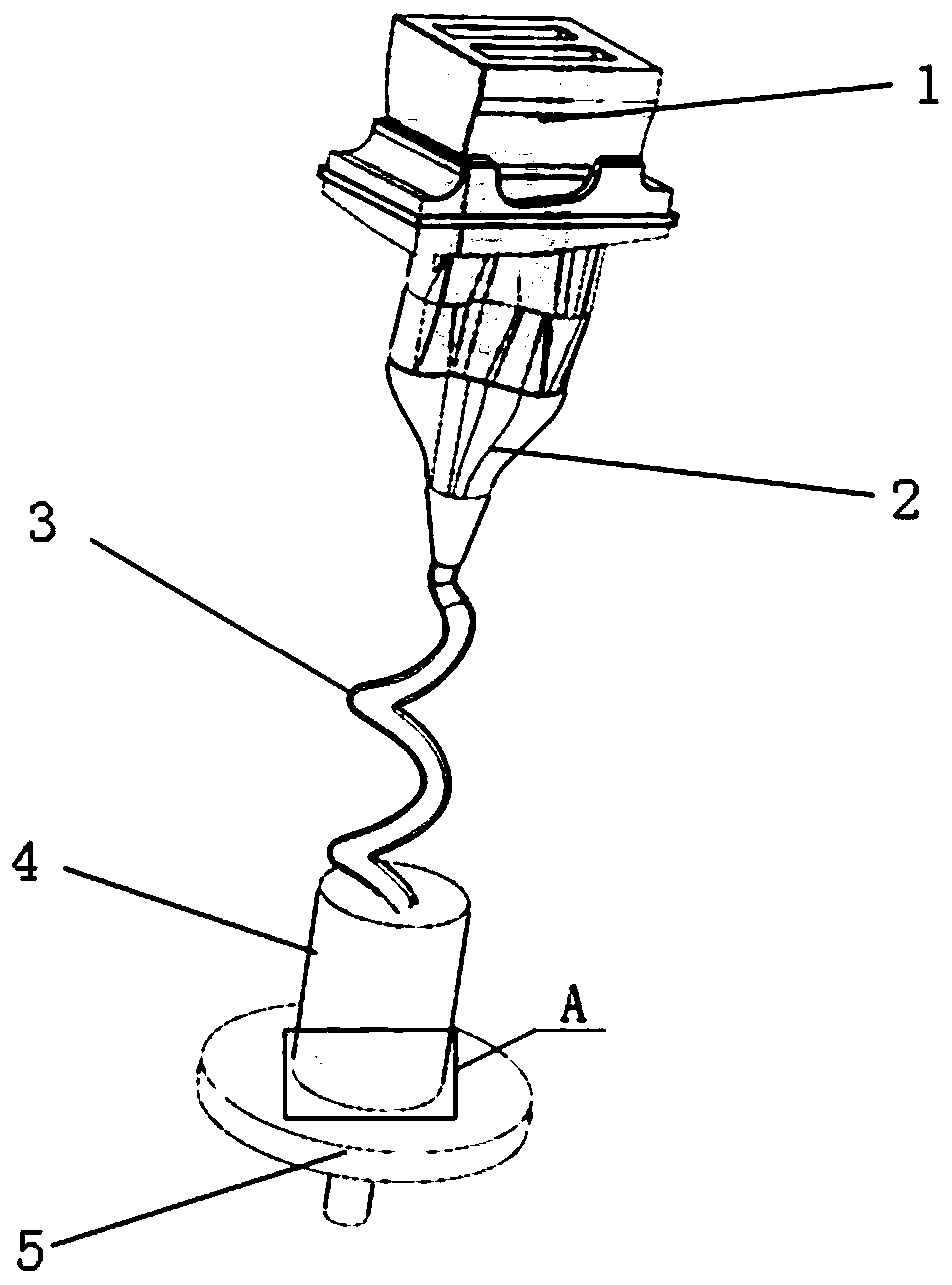

[0034] A method for forming a single crystal part based on gel injection molding with a spiral crystal selector with an embedded structure of a seed crystal block, comprising the following steps:

[0035] Step 1: Manufacture single crystal parts and gel injection integrated resin mold prototypes with a spiral crystal selector embedded in the seed crystal block

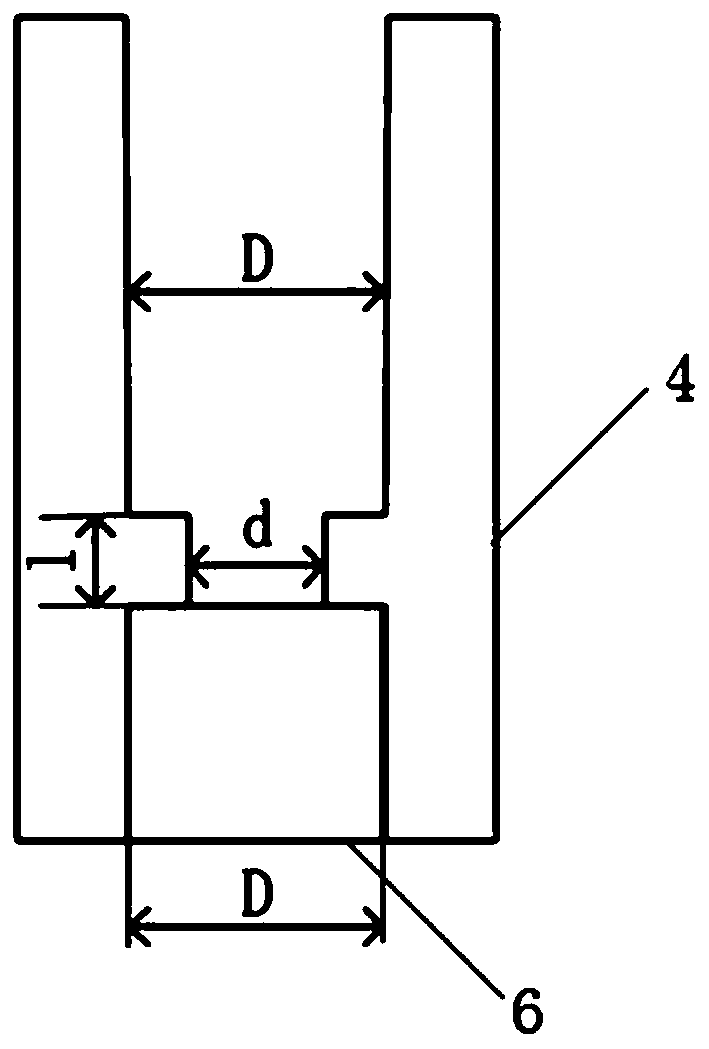

[0036] The invention utilizes light-curing rapid prototyping technology to manufacture resin molds, and determines the structure of each part of the mold according to the requirements of the casting process, mainly including the hollow turbine blade core / shell integrated mold, the spiral crystal selection system, and the water-cooled copper plate. Among them, the appearance of the seeding section of the spiral crystal selector is cylindrical, with a height of 30mm and an outer diameter of 18mm. The interior is a cylinder with transitional rounded corners. The ratio of the outer diameter of the cylinder of the seeding s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com