Cast manufacturing method of rapid sand casting based on SLA prototype

A sand casting and casting technology, which is applied in the field of rapid sand casting and mould manufacturing, can solve the problem of not establishing a rapid sand casting process parameter library, and achieve the effects of saving manpower and material resources, improving efficiency and accuracy, and shortening engineering time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The invention discloses a casting mold manufacturing process parameter correction method for rapid sand casting based on SLA prototype, which includes correcting casting line shrinkage ε and draft angle.

[0042] As a preferred mode, the linear shrinkage rate ε of the casting is according to the formula: ε =(1+ ε 合金 ) / (1- ε SLA树脂 ) for correction, where ε 合金 and ε SLA树脂 are the linear shrinkage rates of the alloy and SLA resin respectively, and the draft angle is increased by 45% on the basis of the value specified in the traditional process ("Casting Handbook (Volume 5, Casting Process)", Machinery Industry Press, 2003) %~97%.

[0043] As a preferred mode, the corrected casting linear shrinkage ε is shown in Table 1, and the corrected draft angle is shown in Table 2. A library of process parameters for different casting materials and sizes for rapid sand casting based on SLA prototypes was established.

Embodiment 2

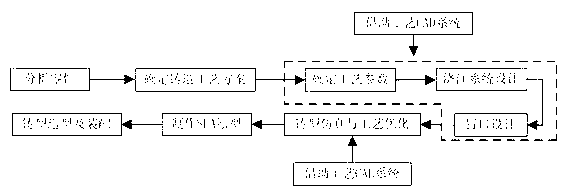

[0045] Adopt the casting mold manufacturing process of the rapid sand mold casting based on SLA prototype described in the present invention to prepare casting mold, specifically comprise the following steps:

[0046] 1) Analyze the part. Analyze the shape and size of parts to obtain measurement data.

[0047] 2) Determine the mold making plan (pouring position, parting surface, quantity and arrangement of castings in the sand box, sand core design, outer mold design of castings).

[0048] 3) Using the process parameter correction method described in the present invention to determine the process parameters. Set process parameters including machining allowance, casting line shrinkage, draft angle, non-processing wall thickness negative allowance, minimum wall thickness, minimum casting hole, reverse deformation, process correction amount and parting negative number, etc. The process parameters are set according to the regulations ("Casting Handbook (Volume 5, Casting Process...

Embodiment 3

[0056] Adopt the casting mold manufacturing process of the rapid sand mold casting based on SLA prototype described in the present invention to prepare casting mold, specifically comprise the following steps:

[0057] 1) Analyze the part. Analyze the shape and size of parts to obtain measurement data.

[0058] 2) Determine the mold making plan (pouring position, parting surface, quantity and arrangement of castings in the sand box, sand core design, outer mold design of castings).

[0059] 3) Using the process parameter correction method described in the present invention to determine the process parameters. Set process parameters including machining allowance, casting line shrinkage, draft angle, non-processing wall thickness negative allowance, minimum wall thickness, minimum casting hole, reverse deformation, process correction amount and parting negative number, etc. The process parameters are set according to the provisions of the "Casting Handbook (Volume 5, Casting Pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com