Mounting base for mounting automobile back door gas spring

A technology of mounting seat and back door, applied in the direction of doors, vehicle parts, transportation and packaging, etc., can solve the problems of insufficient rigidity of gas spring installation points, high material requirements, and high production costs, so as to improve material utilization, improve Stiffness requirements, improve the effect of the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

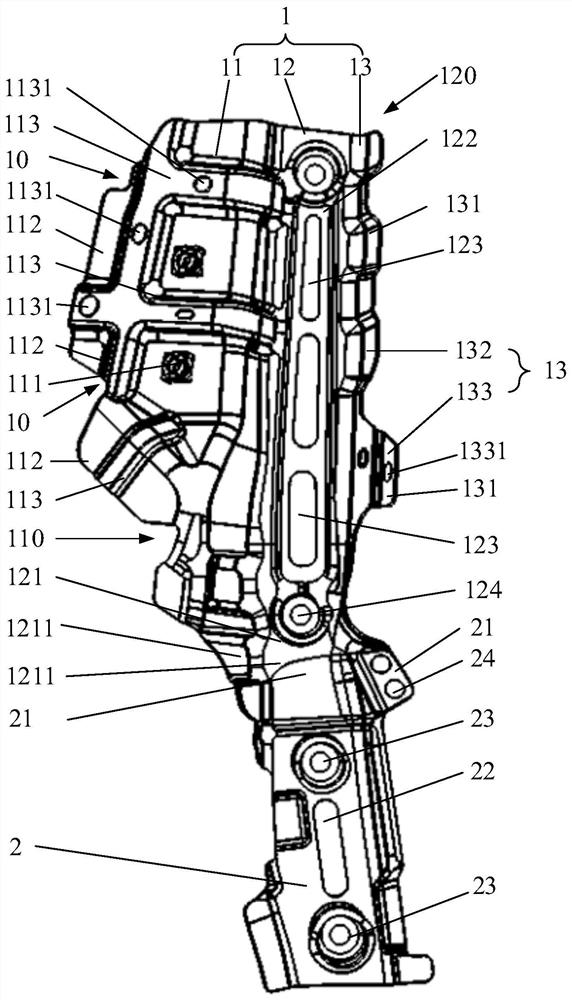

[0033] In order to make the purpose, technical solution and advantages of the present disclosure clearer, the implementation manners of the present disclosure will be further described in detail below in conjunction with the accompanying drawings.

[0034] The embodiment of the present disclosure provides a mounting seat for installing the gas spring of the back door of an automobile. In order to introduce the mounting seat more clearly, the rear door of the car and the gas spring are firstly introduced below:

[0035] The back door of a car generally includes a back door inner panel and a back door outer panel stacked together, the back door inner panel faces the trunk of the car, and the back door outer panel faces the outside of the car. The gas spring is used to support the opened back door, one end of the gas spring is installed on the inner panel of the back door, and the other end of the gas spring is installed on the opening edge of the trunk.

[0036] figure 1 is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com