A seven-degree-of-freedom-three-branch parallel symmetrical mechanism for plate splicing

A technology of symmetrical mechanism and three branch chains, which is applied in manipulators, program-controlled manipulators, metal processing, etc., can solve the problem that the motion envelope is small and does not have the function of moving different plates, and achieves the effect of efficient movement and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better illustrate the present invention, the present invention will be described in detail with a preferred embodiment and with accompanying drawings, specifically as follows:

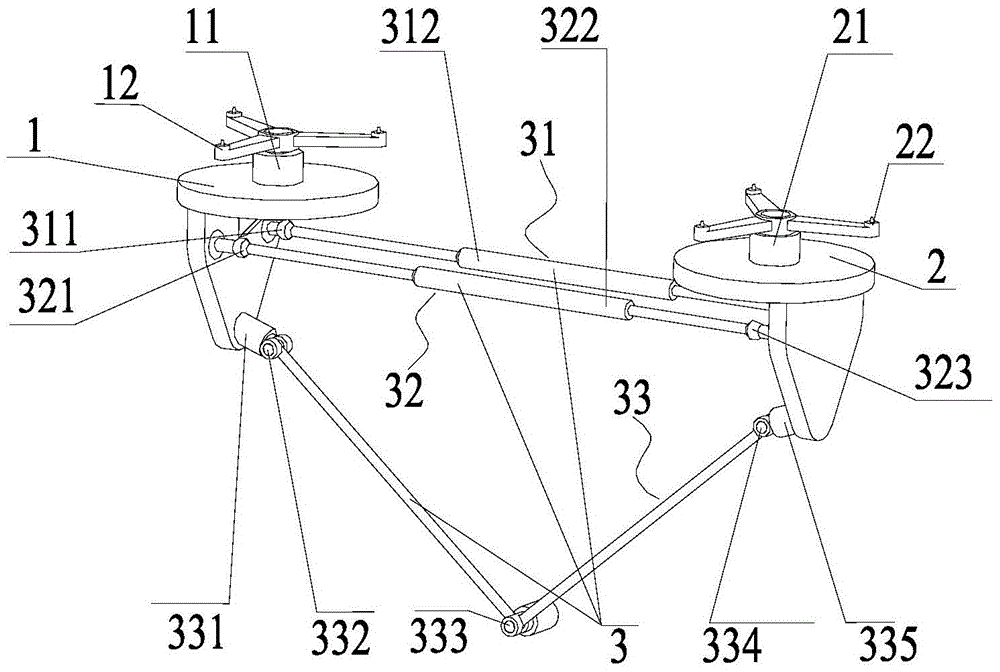

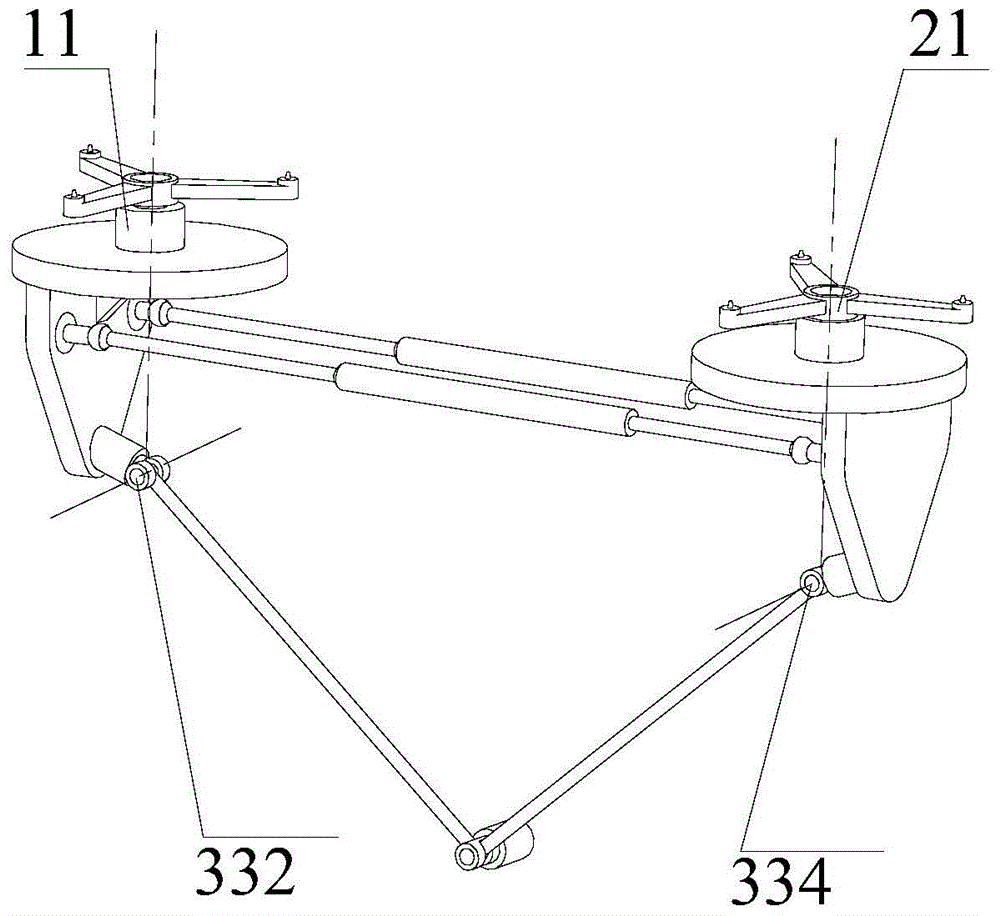

[0019] Such as figure 1 As shown, the seven-degree-of-freedom-three-branch parallel symmetrical mechanism provided in this embodiment includes an upper platform 1 , a lower platform 2 , and three branch chains 3 connecting the upper platform 1 and the lower platform 2 . Among them, the upper platform 1 and the lower platform 2 are connected by three branch chains 3 in the form of 2SPS+RRRRR. Specifically, the three branches include a first branch 31 , a second branch 32 and a third branch 33 . The first branch chain 31 and the second branch chain 32 have the same structure and are arranged in parallel. They are all 2SPS branch chains. ), the second branch chain 32 respectively includes a ball pair 321, a translation pair 322, and a ball pair 323; the third branch chain 33 is a RRRR...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com