Patterning method of ITO (indium tin oxide) film

A patterning and thin-film technology, applied in chemical instruments and methods, electrical components, circuits, etc., can solve the problems of batch etching, low etching efficiency, flammable zinc powder, etc., and achieve stable and reliable reaction rate, high etching The effect of eclipse selection ratio and high selection ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

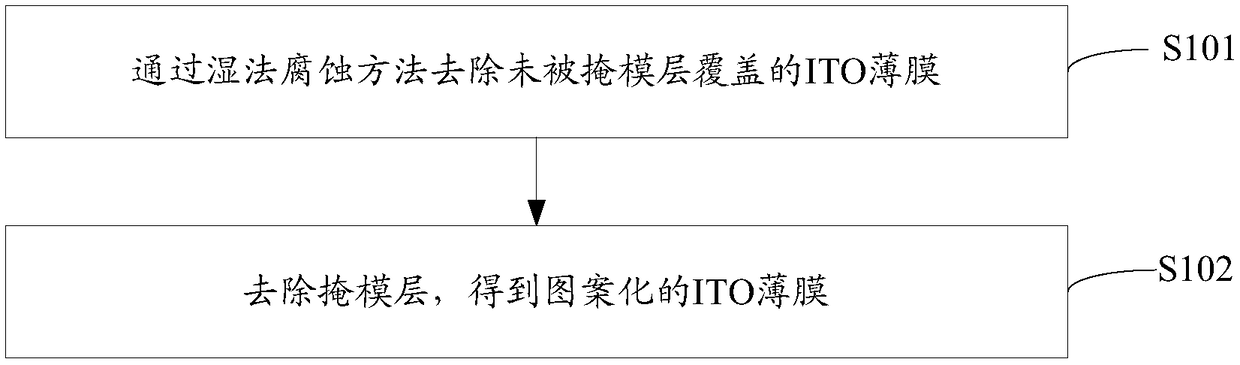

Method used

Image

Examples

Embodiment 1

[0059] The corrosion solution and volume ratio used are as follows:

[0060] h 3 PO 4 : 80±10%;

[0061] CH 3 COOH: 10±10%;

[0062] HNO 3 : 10±10%;

[0063] h 2 O: 50%.

[0064] The temperature of the etching solution is 60°C,

[0065] Corrosion time is 4 minutes;

[0066] The experimental results are: etching line width loss 50:1, selectivity ratio to quartz>10000:1, selectivity ratio to Ti and TiN>1000:1.

Embodiment 2

[0068] The corrosion solution and volume ratio used are as follows:

[0069] h 3 PO 4 : 80±10%;

[0070] CH 3 COOH: 10±10%;

[0071] HNO 3 : 10±10%;

[0072] h 2 O: 50%.

[0073] The temperature of the etching solution is 20°C,

[0074] The corrosion time is 8 minutes;

[0075] The experimental results are: etching line width loss 100:1, selectivity ratio to quartz>10000:1, selectivity ratio to Ti and TiN>10000:1.

[0076] The above are the specific implementation manners of the present application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com