Pulsator washing machine with multiple washing modes

The technology of a pulsator washing machine and washing method, which is applied to a washing machine with a container, other washing machines, washing devices, etc., can solve the problems of low washing efficiency, complex structure of the pulsator washing machine, unsatisfactory washing effect, etc., and achieve good washing effect. , Improve washing effect and washing efficiency, Improve washing efficiency and washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

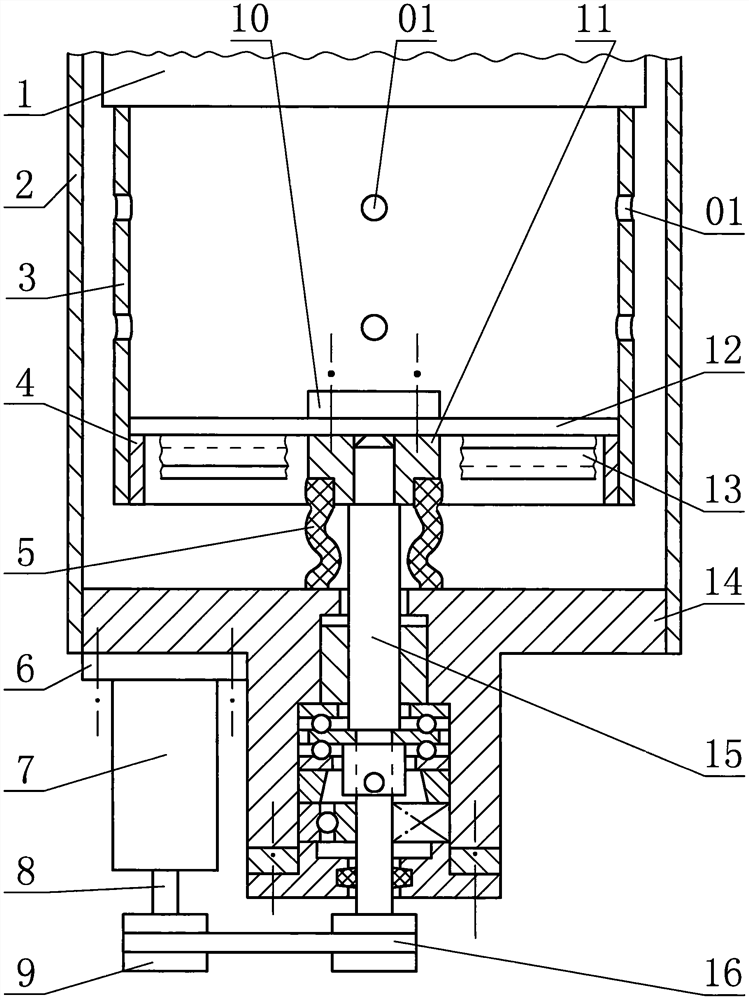

[0067] Those skilled in the art can design many specific implementations based on the technical solution, so the following specific implementations are only examples to illustrate the technical solution. Combine below Figure 1 to Figure 22 , the present invention is further described:

[0068] Figure 1 to Figure 6 and Figure 9 A pulsator washing machine with multiple washing methods is shown, including a tub, a dehydration tub, and a motor. The tub includes side walls and a bottom wall of the tub. The motor is installed on the bottom of the bottom wall of the tub. The motor can rotate in both forward and reverse directions, and the dehydration bucket is located in the water storage bucket. wall, the bottom of the side wall of the dehydration bucket is connected with the bottom wall of the dehydration bucket, and the side wall of the dehydration bucket has a plurality of water holes passing through the inner and outer spaces of the dehydration bucket; the bottom wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com