Grinding device and dismantling method for high-speed rail track milling and grinding car

A milling and grinding car and grinding technology, applied in the directions of track, track maintenance, laying track, etc., can solve the problems of affecting work efficiency, large size and weight of grinding wheels, improve reliability and convenience, and ensure operation. The effect of stability and improved disassembly reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

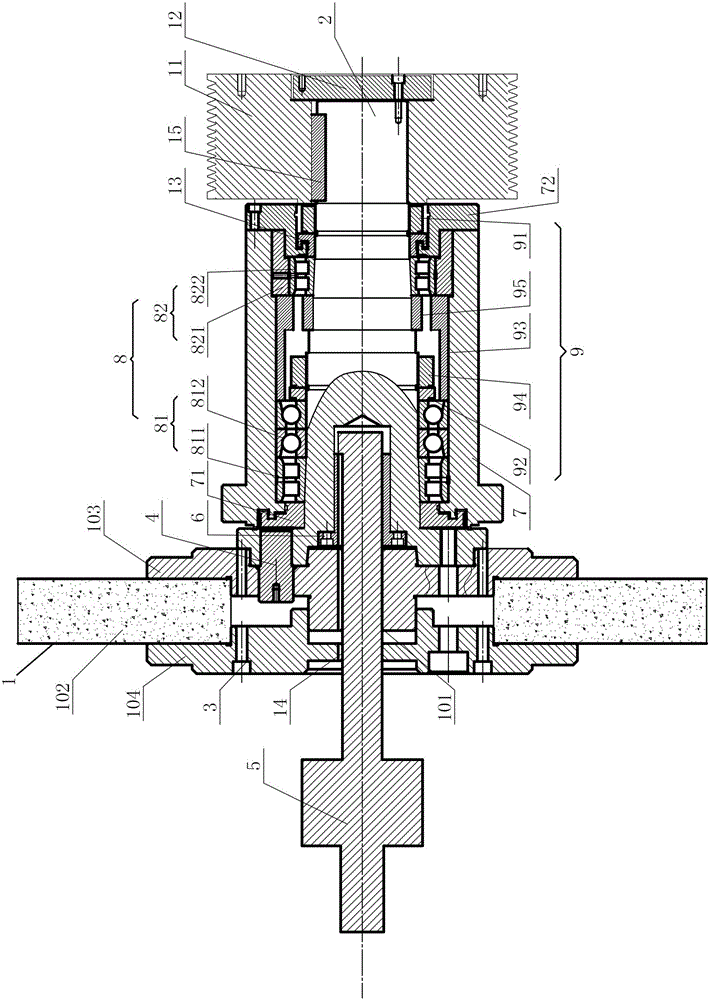

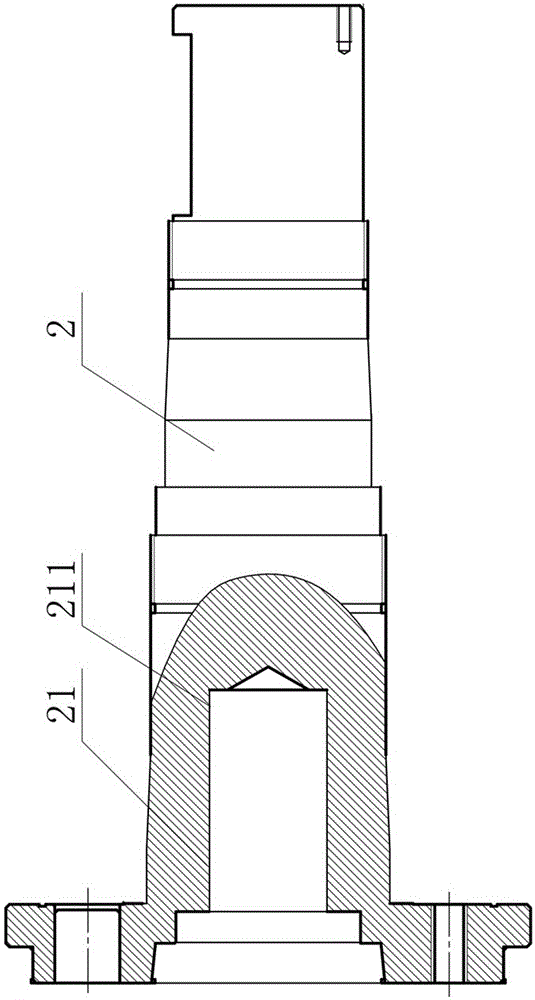

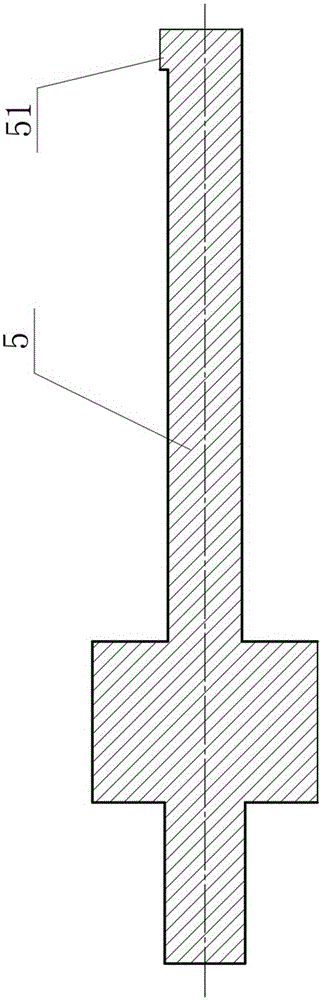

[0034] like Figure 1 to Figure 5 As shown, the grinding device for high-speed rail track milling and grinding vehicles in this embodiment includes a grinding wheel assembly 1 and a grinding spindle 2 that drives the grinding wheel assembly 1 to rotate. The grinding wheel assembly 1 includes a grinding wheel 102, a grinding wheel flange body 103 and a grinding wheel method. The flange cover 104, the grinding wheel 102, the grinding wheel flange body 103 and the grinding wheel flange cover 104 are connected by fasteners, the grinding wheel 102 is pressed between the grinding wheel flange body 103 and the grinding wheel flange cover 104, the grinding spindle 2 and the grinding wheel assembly 1 is provided with a locking screw 3 to limit the axial displacement of the two and a transmission pin 4 to limit the circumferential displacement of the two. Insert the first removal hole 61 of the removal rod 5, the grinding wheel assembly 1 is provided with a second removal hole 101 corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com