A machine tool

A technology of machine tools and clamping mechanisms, applied in machine tool parts, metal processing machinery parts, processing and manufacturing, etc., can solve problems such as expensive and complicated pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

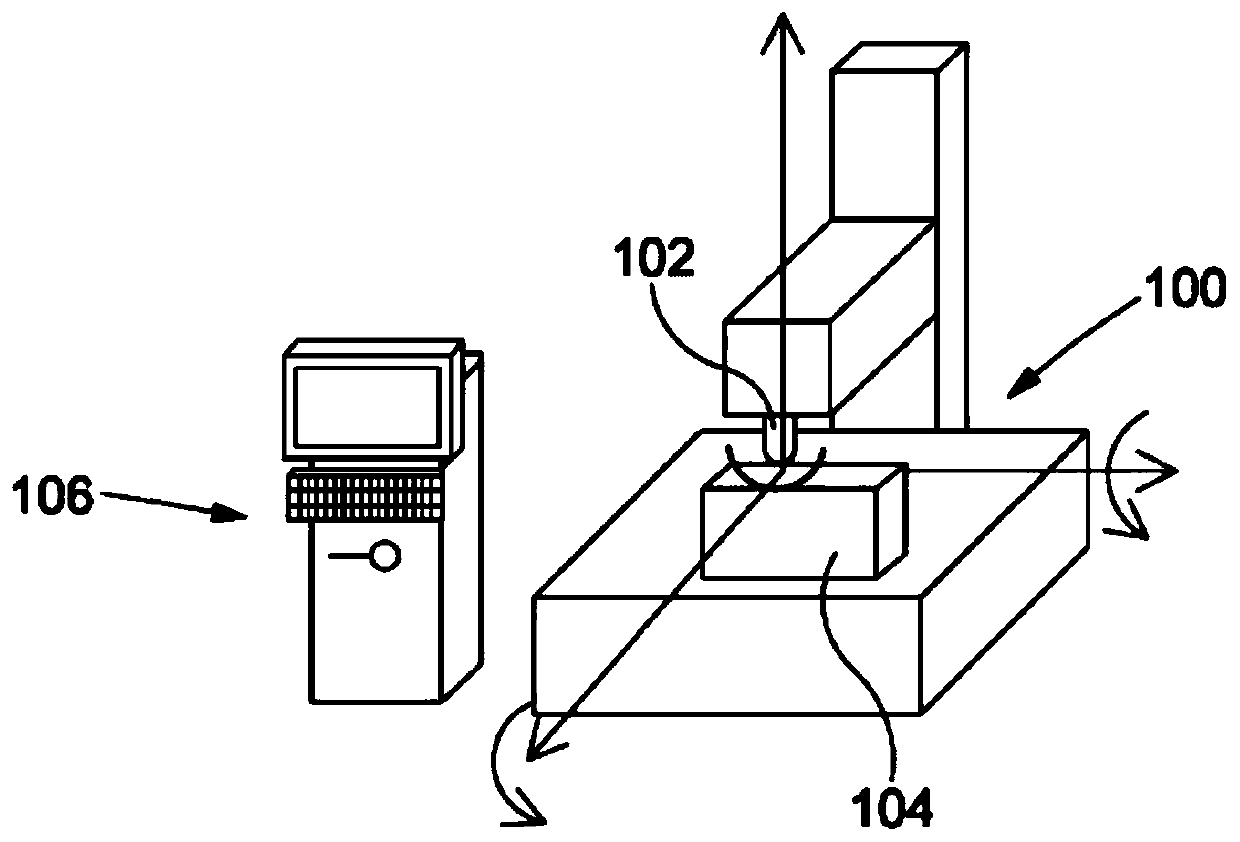

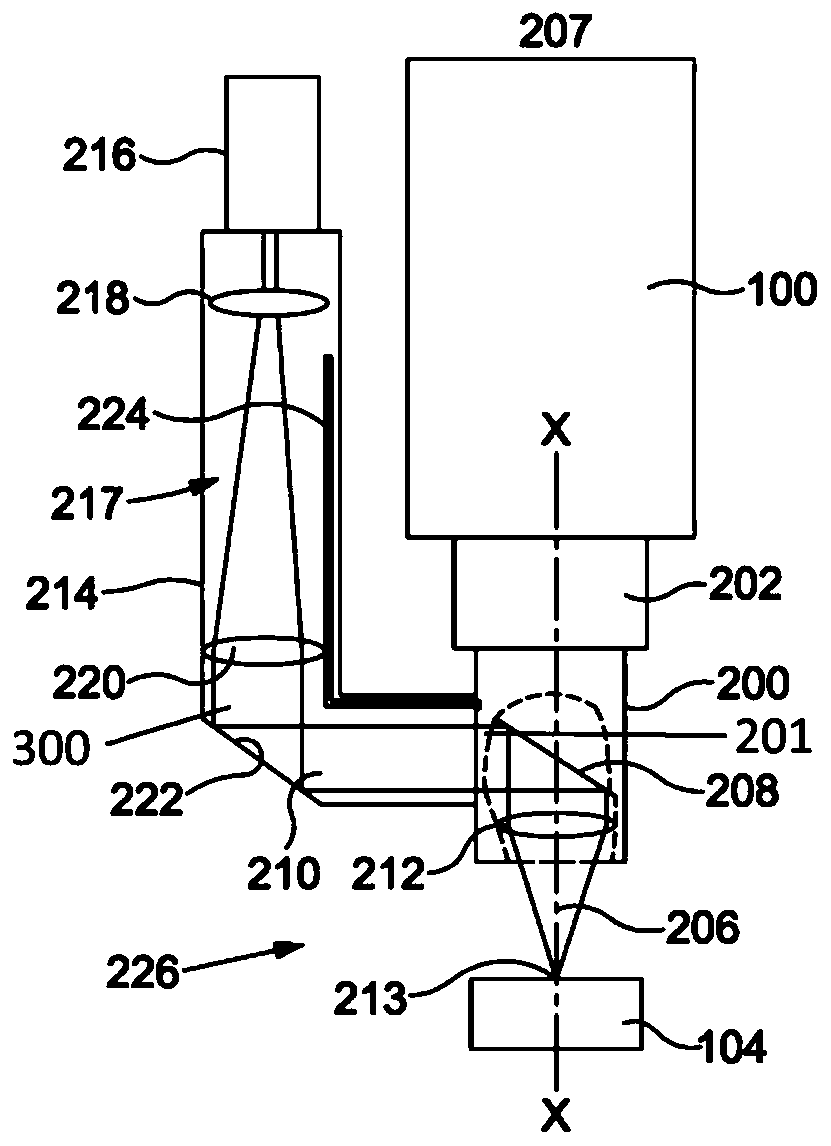

[0115] figure 1 is a schematic diagram of an exemplary automatic driving system according to some embodiments of the present application. In some embodiments, the machine tool 100 includes a clamping mechanism, a processing head 102 retained in the clamping mechanism, and the processing head 102 is configured to machine a workpiece 104 . In some embodiments, machine tool 100 is generally controlled by controller 106 , which controls the position of processing head 102 as processing head 102 processes workpiece 104 .

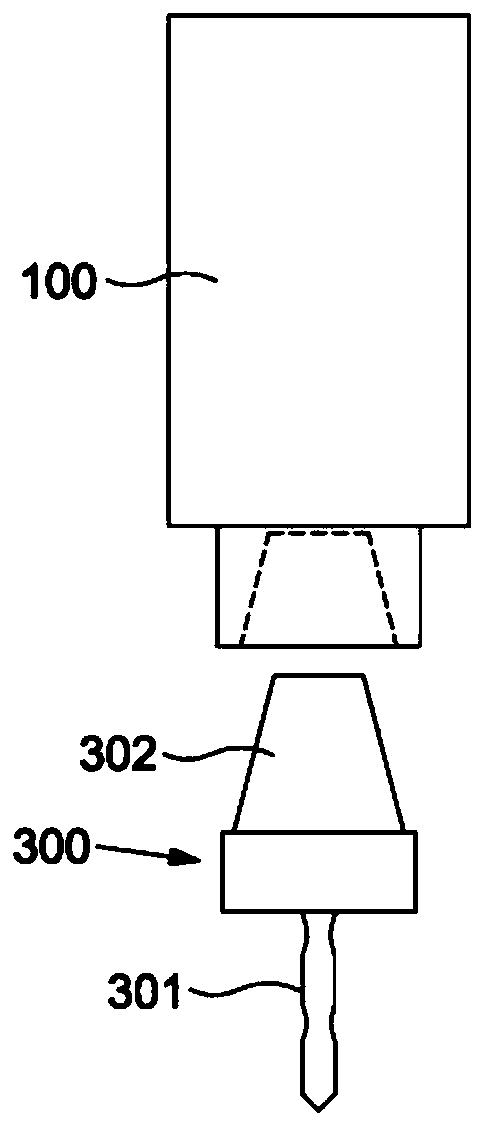

[0116] Most machine tools 100 are configured so that processing heads 102 are interchangeable with other processing heads 102 in order to provide the correct processing head 102 for the machining task at hand. Taking a milling machine as an example for illustration, the provided first processing head can be used for rough machining, and the provided second processing head can be used for finishing machining.

[0117] Correspondingly, in some embodiments, the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com