Construction method for longitudinally and flexibly splicing newly-built bridge and current bridge

A construction method and bridge technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems affecting the durability of structures, cracks at the upper connection position, sudden changes in height at splicing joints, etc., to improve structural durability , The construction work area is small, and the effect of preventing rainwater seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

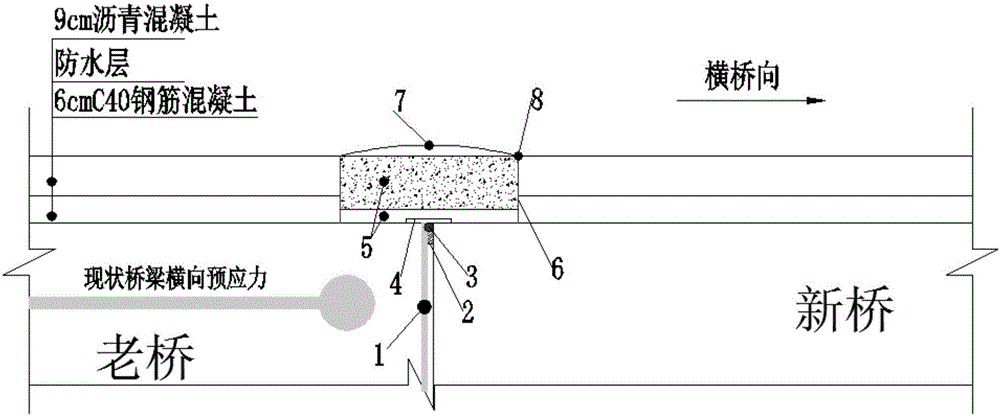

[0092] The method, such as figure 1 shown, including,

[0093] (1) Re-measure the elevation of the concrete top surface of the longitudinal joint part 1 of the existing bridge and check the elevation of the new bridge;

[0094] (2) Use diamond chains to cut the existing bridge anti-collision wall horizontally and vertically, so that the joint structure size of the existing bridge after cutting is complete;

[0095] (3) Overall construction bridge deck asphalt pavement:

[0096] (3.1) The seam part 1 is clothed and paved by a small loader;

[0097] (3.2) The seam part 1 is rolled by a steel wheel roller;

[0098] (3.3) Pave asphalt on the wide bridge deck;

[0099] (3.4) Leveling control is carried out on both sides of the seam part 1;

[0100] (4) Flexible splicing construction of seams:

[0101] (4.1) Stake out, mark the center line according to the center position of the seam part 1, and then release the construction side lines of 20cm to both sides according to the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com