Quick assembling-disassembling plastic building angle adjustable formwork

A formwork and angle adjustment technology, which is used in construction, building construction, formwork/formwork/work frame, etc., can solve the problems of inability to adapt to ever-changing building structures, poor connection between wooden boards and plastic formwork, waste of wood resources, etc. The effect of fast splicing, shortening construction period and saving wood resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

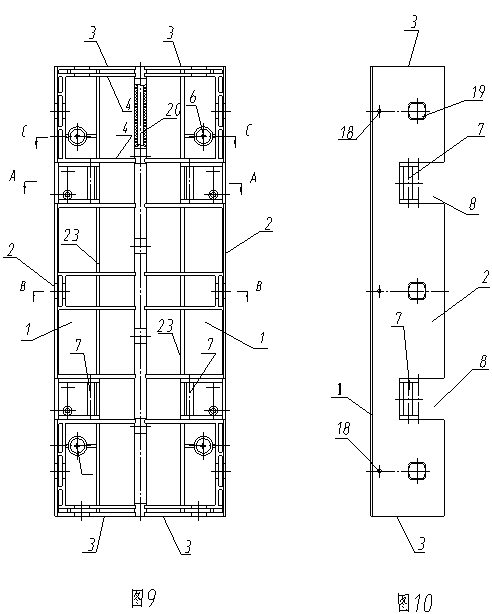

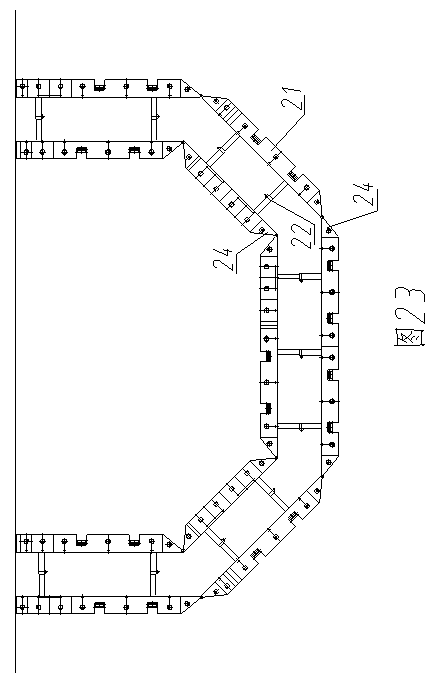

[0040] In this embodiment, the quick disassembly and assembly adjustable angle formwork for plastic buildings is composed of a standard board with a length of 1000mm and a set of boards with a length of 500mm, 200mm, 100mm, 50mm, 20mm, and 10mm, and can also have lengths More than 1000mm extension plate to improve the efficiency of on-site installation. In this way, the corners of any size and length in actual construction can be completely filled with several adjustable angle formworks in this group of lengths, without additional use of wood. For example: a corner with a length of 3670mm can be spliced with three 1000mm, one 500mm, one 100, one 50mm, and one 20mm adjustable angle templates.

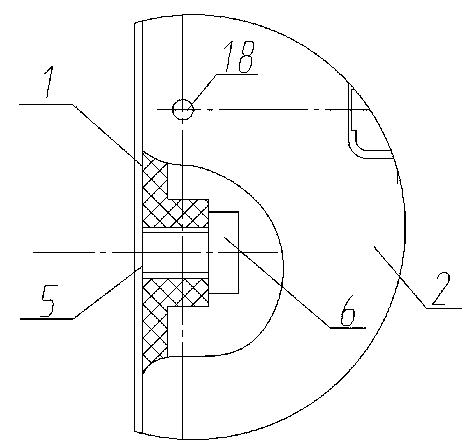

[0041] In this embodiment, the length of the quick disassembly and assembly plastic building adjustable angle template is equal to or greater than 50mm, and a plurality of transverse triangular ribs 4 are arranged in the lateral triangular ribs 3 on the outer sides of the two ends to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com