Square and rectangular tube pre-welding machine of JCO unit

A square and rectangular tube, pre-welding machine technology, applied in welding equipment, tubular objects, welding equipment and other directions, can solve the problems of inability to meet production needs and small application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

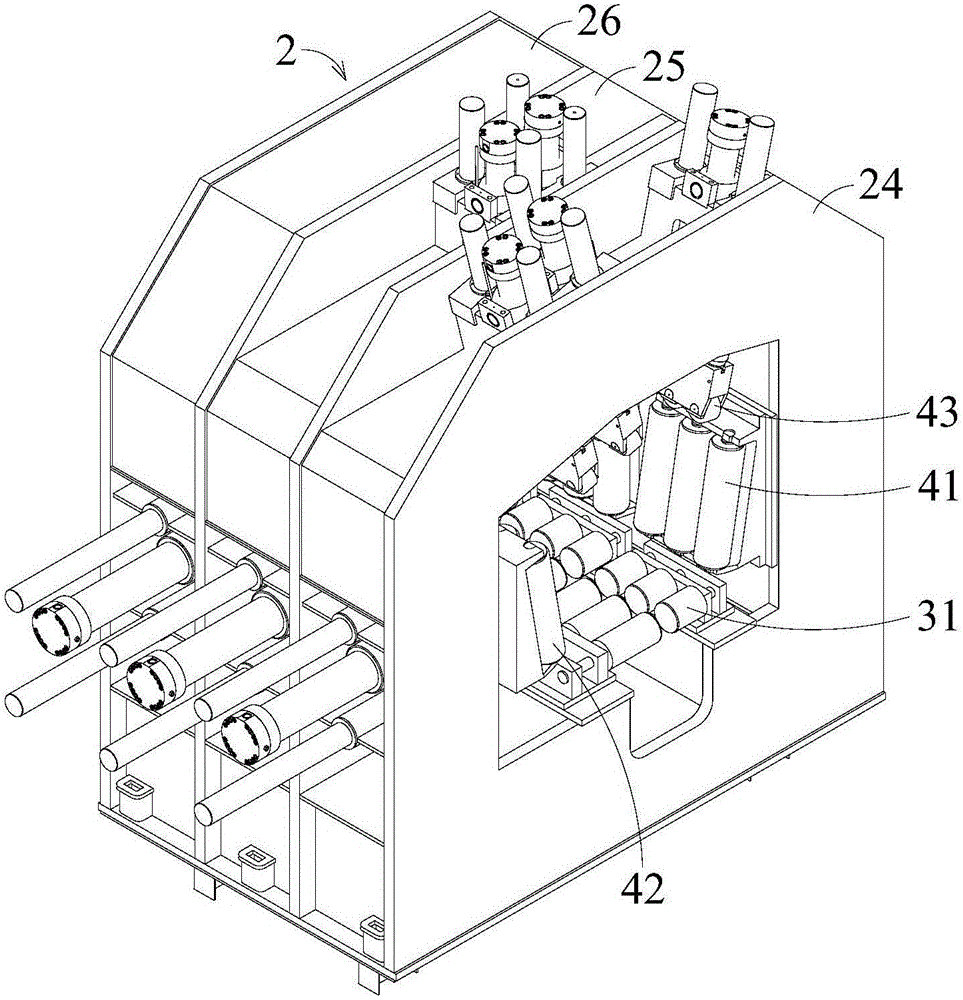

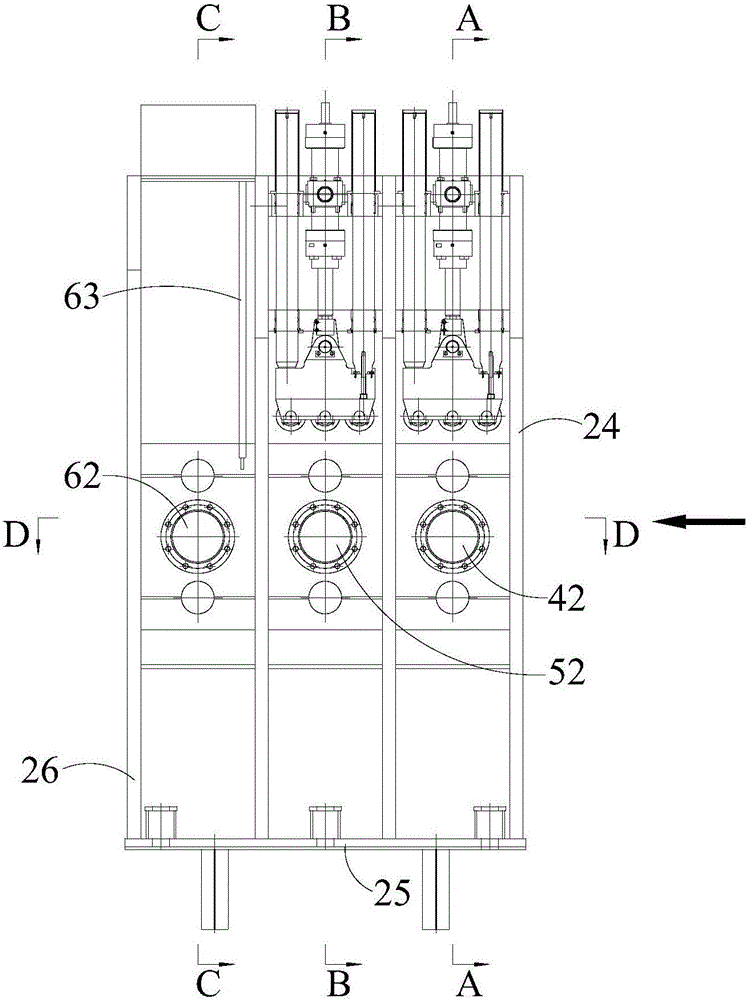

[0032] refer to figure 1 , in this embodiment, figure 1 A schematic diagram of the three-dimensional structure of the square and rectangular tube pre-welding machine (hereinafter referred to as the pre-welding machine) of the JCO unit embodying the principle of the present invention is representatively shown in . In this exemplary embodiment, the square and rectangular tube pre-welding machine of the JCO unit proposed by the present invention is taken as an example of the pre-welding equipment in the JCO unit. Further, the square rectangular tube pre-welding machine of the JCO unit proposed by the present invention is an example of a unit of a straight seam submerged arc welded pipe extruded from a tube blank in the order of J type→C type→O type. The structural composition and functions of each part of the rectangular tube pre-welding machine will be described. Those skilled in the art can easily understand that in order to realize the above functions, various modifications,...

Embodiment approach 2

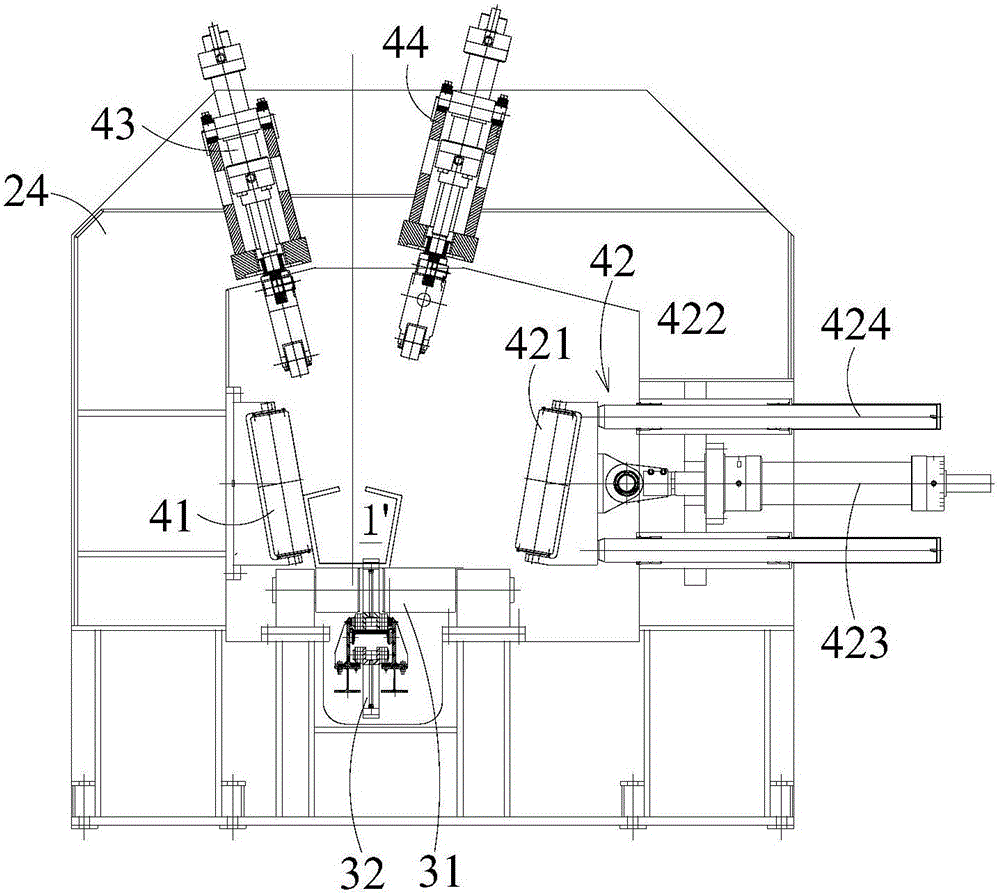

[0054] refer to Figure 7 , Figure 7 Figure 1 shows a representative cross-sectional view of another exemplary embodiment of the square and rectangular tube pre-welding machine of the JCO unit of the present invention, which specifically shows that in this exemplary embodiment, the joint frame 24 of the pre-welder and the seam joint mechanism Structure. Hereinafter, another exemplary embodiment of the square and rectangular tube pre-welding machine of the JCO unit of the present invention will be further described in conjunction with the above-mentioned drawings.

[0055] In this embodiment, the structure and working mode of the pre-welding machine are roughly the same as the above-mentioned embodiment, but the difference is:

[0056] Such as Figure 7 As shown, in this embodiment, the stitching mechanism of the pre-welding machine further includes a third top stitching roller 45 , which is arranged in parallel on the outside of the second top stitching roller 44 . One of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com