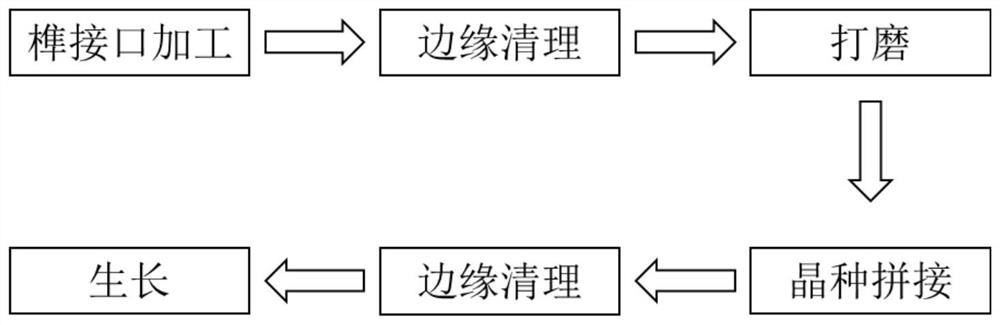

Splicing growth process for large-size monocrystalline diamond

A single crystal diamond and diamond technology, which is applied in the field of large-size single crystal diamond splicing growth process, can solve the problems of high stress at the interface, high growth temperature, not a single crystal growth process, etc., and achieve the effect of good quality and good growth effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

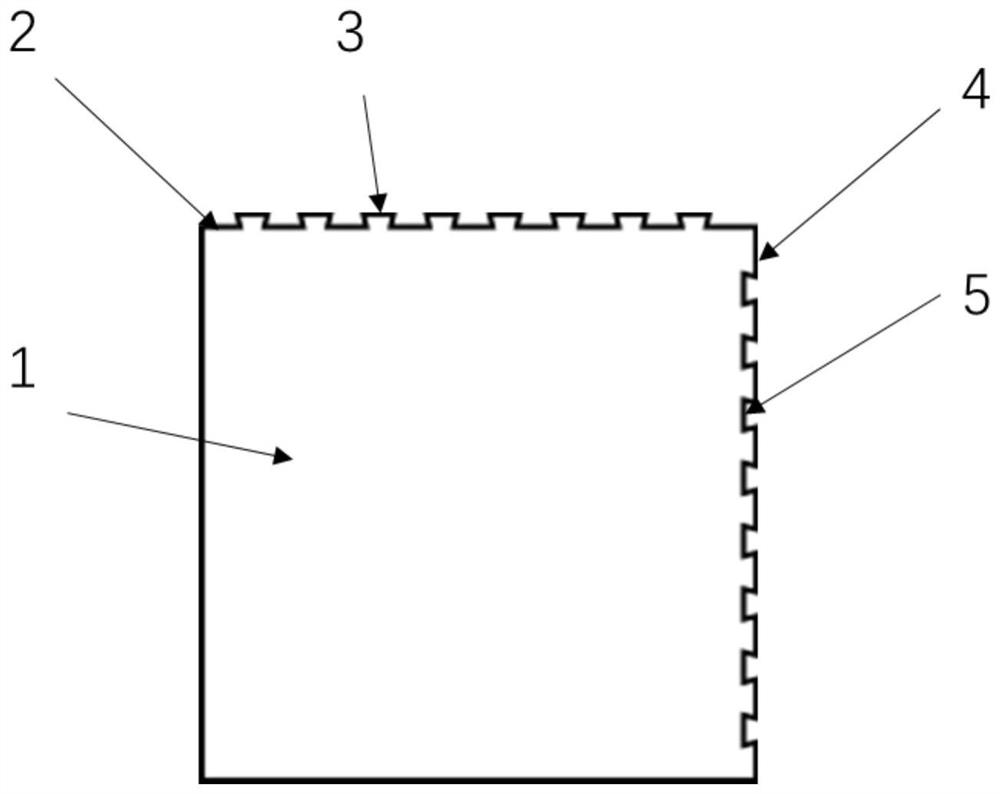

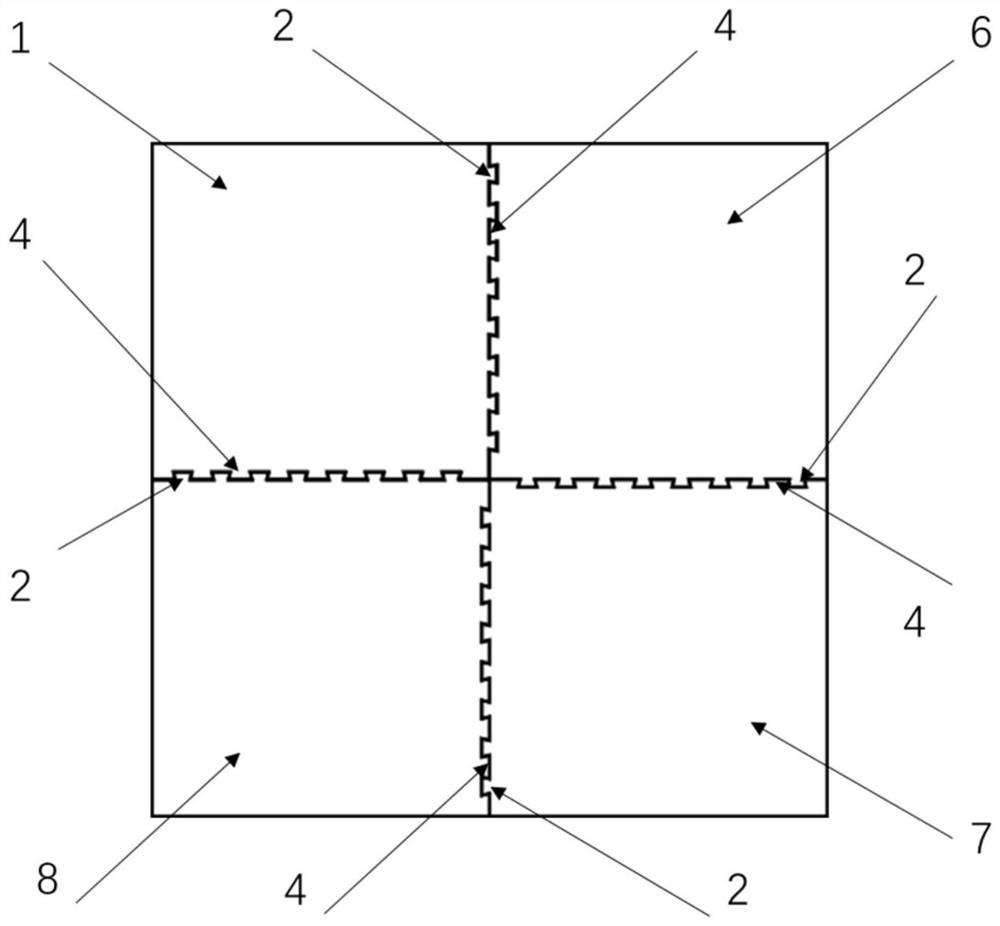

[0033] The diamond crystal seed is a square sheet with a side length of 5 mm and a thickness of 0.3 mm. The two adjacent edges are processed with trapezoidal tenon joints, one side of which is a protruding trapezoidal male head, and the adjacent side is a trapezoidal female with the same shape. mouth. The height of the trapezoidal male head is 200 microns, the length of the upper base is 200 microns, the length of the lower base is 240 microns, and the angle between the lower base and the waist is about 85°. The cleaning of the edge of the mortise joint adopts plasma cleaning, the specific process is a pressure of 80 torr, a power of 2500 watts, a hydrogen flow of 500 SCCM, an oxygen of 2 SCCM, and a cleaning time of 30 minutes. After splicing the diamond sheets, plasma is used for pretreatment. The treatment process is 80 Torr, power 3000 watts, hydrogen flow rate 500 SCCM, treatment temperature 805 degrees Celsius, and treatment for 30 minutes. The diamond sheets after the ...

Embodiment 2

[0036] The diamond crystal seed is a square sheet with a side length of 8 mm and a thickness of 0.3 mm, and trapezoidal tenon joints are processed on two adjacent edges. The height of the trapezoidal male head is 1 mm, the length of the upper base is 1.5 mm, the length of the lower base is 2.5 mm, and the angle between the lower base and the waist is about 65°. The cleaning of the edge of the mortise joint adopts plasma cleaning, the specific process is a pressure of 80 torr, a power of 2500 watts, a hydrogen flow of 500 SCCM, an oxygen of 2 SCCM, and a cleaning time of 30 minutes. After splicing the diamond seeds, plasma is used for pretreatment. The treatment process is 80 Torr pressure, 3000 watts power, 500 SCCM hydrogen flow rate, and 850 degrees Celsius treatment temperature for 30 minutes. The diamond sheets after the pretreatment are spliced and grown by plasma. The growth process is 100 torr pressure, 5000 watts of power, 500 SCCM of hydrogen flow, 30 SCCM of methan...

Embodiment 3

[0039]The diamond crystal seed is a square sheet with a side length of 10 mm and a thickness of 0.3 mm, and trapezoidal tenon joints are processed on two adjacent edges. The height of the trapezoidal male head is 0.5 mm, the length of the upper base is 0.5 mm, the length of the lower base is 1.5 mm, and the angle between the lower base and the waist is 45°. The cleaning of the edge of the mortise joint adopts plasma cleaning, the specific process is a pressure of 80 torr, a power of 2500 watts, a hydrogen flow of 500 SCCM, an oxygen of 2 SCCM, and a cleaning time of 30 minutes. After splicing the diamond sheets, plasma is used for pretreatment. The treatment process is 80 Torr pressure, 3000 watts power, 500 SCCM hydrogen flow, and 850 degrees Celsius treatment temperature for 30 minutes. The diamond sheets after the pretreatment are spliced and then grown by plasma. The growth process is a pressure of 8 torr, a power of 6000 watts, a hydrogen flow rate of 500 SCCM, a methan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com