Construction method of cast-in-place decorative finish bare concrete wall

A technology of fair-faced concrete and construction methods, applied to walls, building components, buildings, etc., can solve the problems of affecting the service life of the wall, the existence of air bubbles in the wall, and the inclination of the wall surface, so as to reduce the maintenance cost of the wall and strengthen Structural strength, effect of reducing dust emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

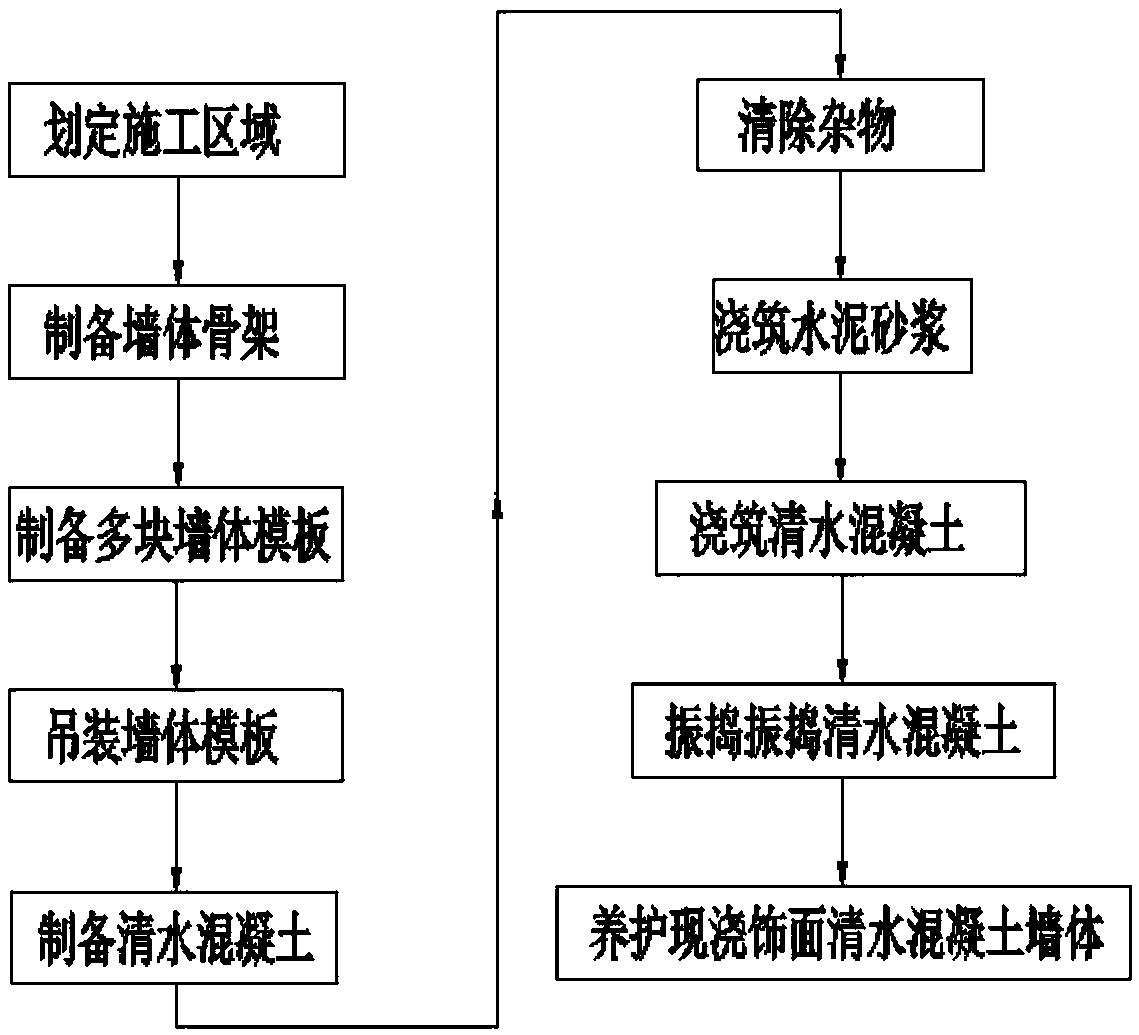

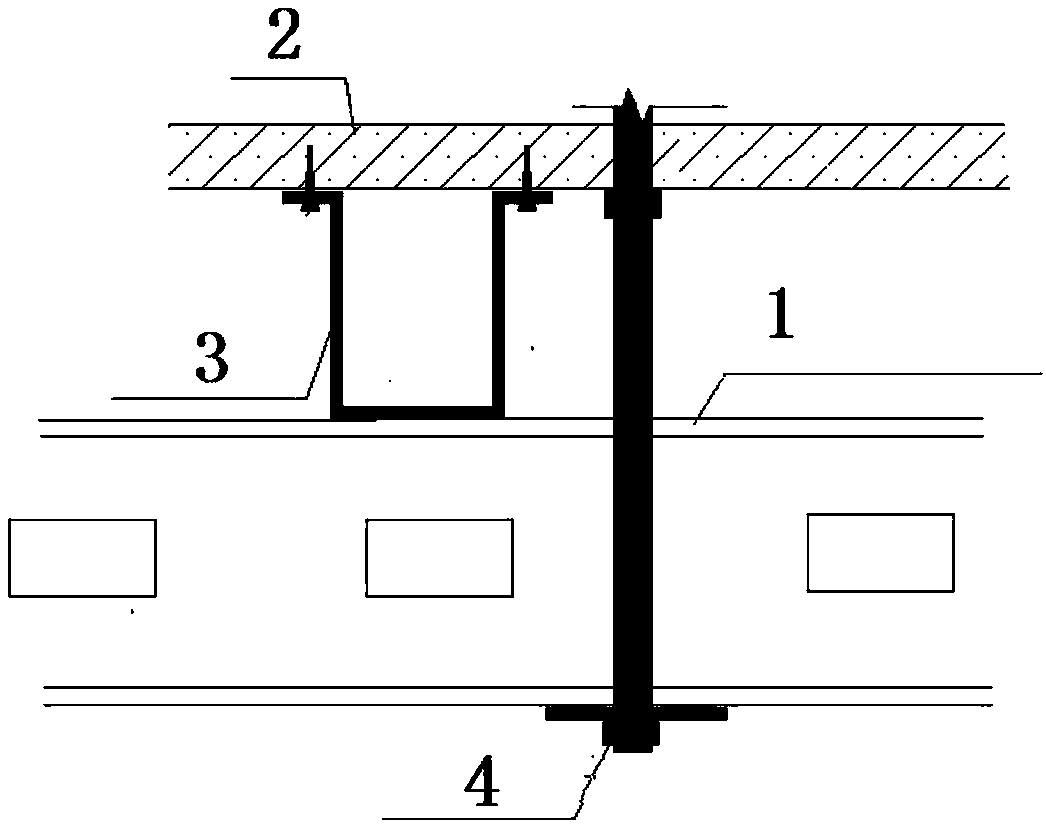

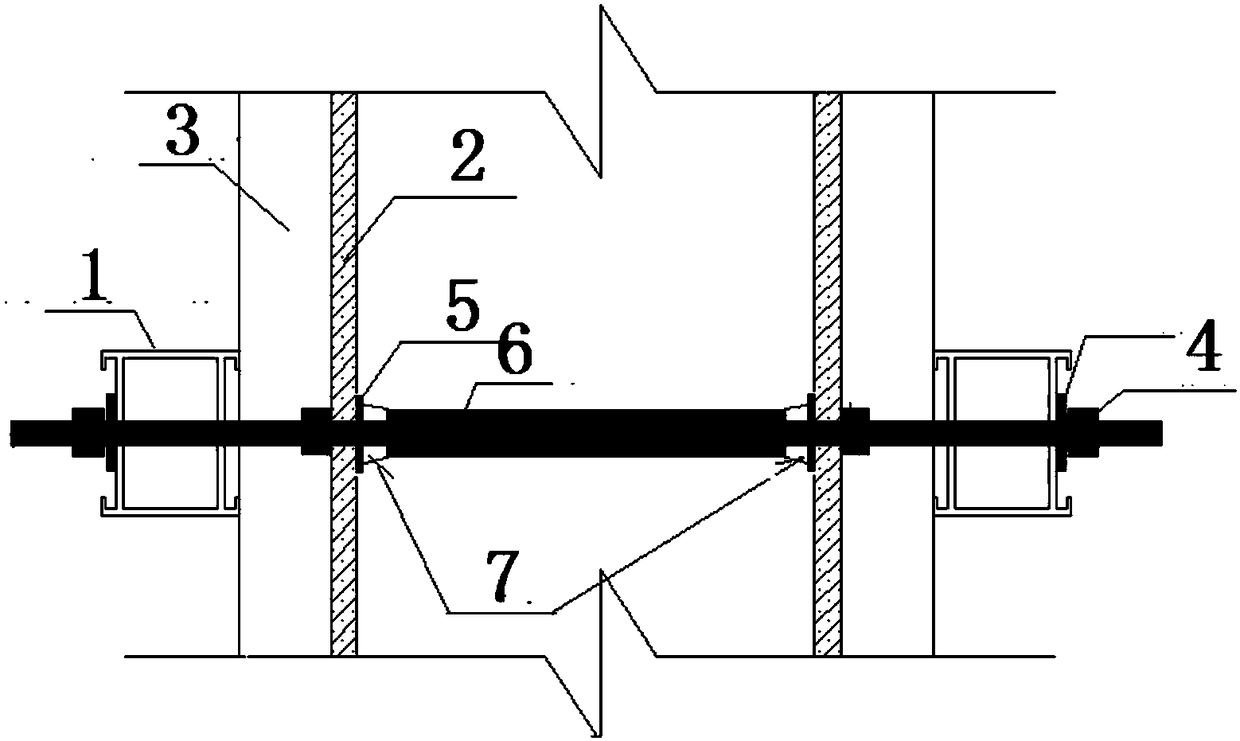

[0039] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown, the present invention provides a kind of cast-in-place facing fair-faced concrete wall construction method, comprises the following steps:

[0040] Step 1: Delineate the construction area: According to the construction drawings, draw a closed circular outline on the ground as the construction area;

[0041] Step 2: Prepare the wall skeleton: lay out several vertical steel bars standing on the ground in the construction area mentioned in step 1, and then arrange several horizontal steel bars along the horizontal direction, and use binding wires to cross-bond the vertical steel bars and the horizontal steel bars Bundled together at all places, so that the vertical steel bars, horizontal steel bars and binding wires are connected to form the wall skelet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com