Micron-nano grade three-dimensional measurement '331' system and measurement method thereof

A three-dimensional measurement, micro-nano technology, applied in the direction of measuring devices, mechanical measuring devices, instruments, etc., can solve problems such as high cost and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

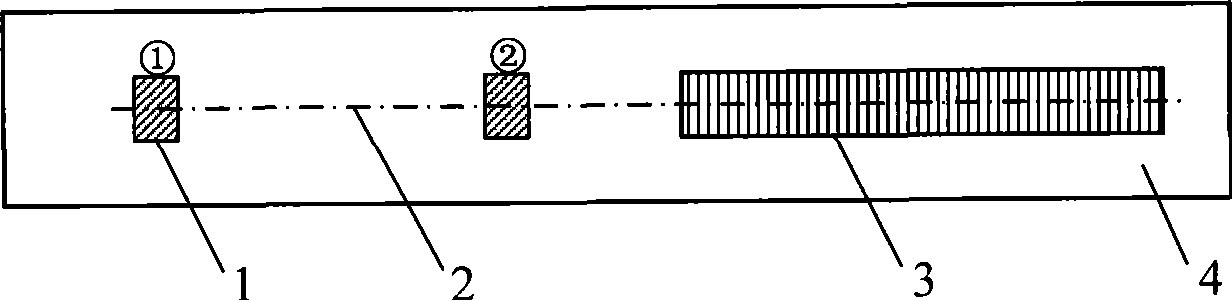

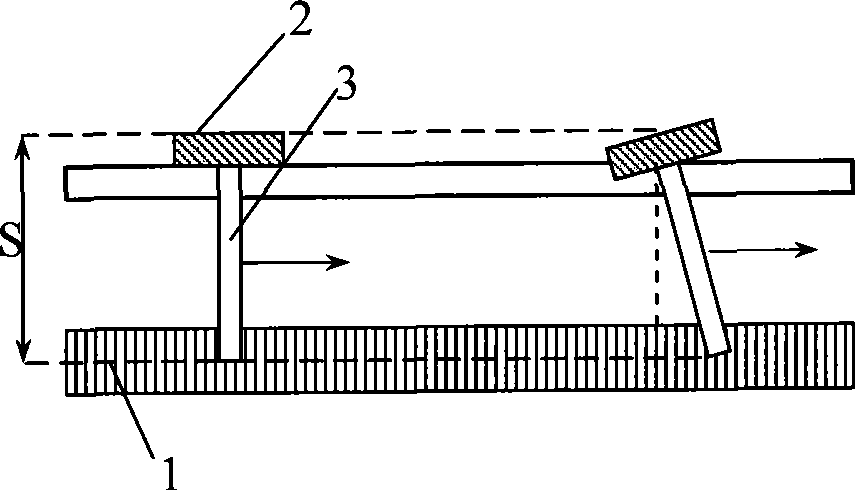

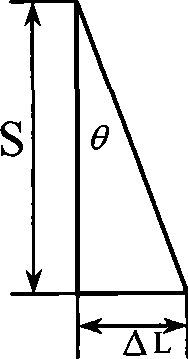

[0050] Figure 7 Shown is a schematic diagram of the three-dimensional motion structure system that satisfies the "331 principle" of three-line collinear, three-plane co-planar and point-plane coincidence.

[0051] In order to achieve a structural layout that conforms to the "331 Principle", precise adjustments are required during structural assembly. The actual adjustments are divided into the following four steps:

[0052] 1. Adjust the co-planar 3D motion system and the three-line co-point system

[0053] Such as Figure 5 As shown in d, first assemble the three-dimensional coplanar system; the whole three-dimensional motion table is mainly composed of the X-direction slide seat 1 ( Figure 5 shown in a), Y-direction slide seat 2 ( Figure 5 As shown in b), working slide 3 ( Figure 5 c) and Z-direction adjustable workbench 4 ( Figure 5 As shown in c), these four parts are composed of a structural layout that is nested one by one from the outside to the inside, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com