Permanent magnetic motor gullet torque measuring method

A technology of cogging torque and permanent magnet motor, which is applied in the directions of torque measurement, measuring device, power measurement, etc., can solve the problems of lack, measurement error, angle sensor accuracy and high resolution requirements, so as to improve the accuracy and reduce the Response to performance requirements, the effect of reducing horizontality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

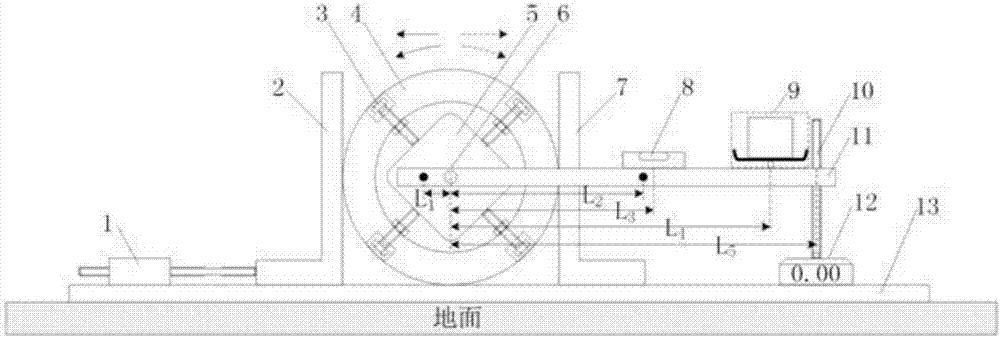

[0013] First embodiment: figure 1 Shown is the cogging torque measurement system for the case of a flat rail. The system components mainly include: precision mobile platform (1), baffles (2) and (7), circular housing (4) and positioning bolts (3), motor under test (5), level ruler (8), accessories Weight (9), screw rod (10), balance bar (11), electronic scale (12) and guide rail (13). The characteristics and measurement steps of the cogging torque measurement system are as follows.

[0014] 1. The motor under test (5) is adjusted to be located at the geometric center of the circular housing (4) through the positioning bolts (3), and the motor under test (5) is tightly connected to the circular housing (4); The motor (5) forms tangential contact with the guide rail (13) through the circular casing (4), and its position on the guide rail is positioned by means of the baffles (2) and (7).

[0015] 2. The motor shaft (6) is tightly connected to the balance bar (11), and the con...

no. 2 example

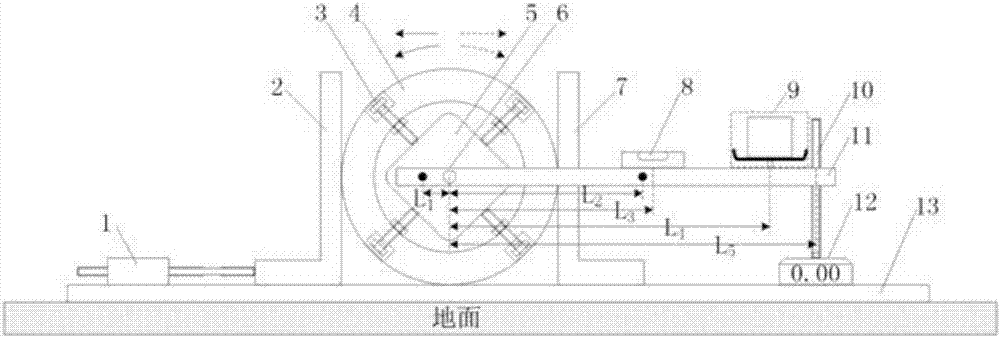

[0021] Second embodiment: figure 2 Shown is the cogging torque measurement system for the case of a sloped guide rail. Referring to the comparative first embodiment ( figure 1 ), the cogging torque measurement system for the slope guide rail case ( figure 2 ) of the characteristics and measurement steps are.

[0022] 1. From the system components, the cogging torque measurement system of the slope guide rail has added a slope pad (14). The slope pad (14) is used to pad one end of the guide rail (13) to form a slope guide rail; and the slope angle φ Meet: G m *sin( φ ) m , where G m is the gravity of the motor under test (5), F m is the maximum static friction force of the tested motor (5) on the guide rail (13).

[0023] 2. In terms of the movement process, when it needs to move on the guide rail (13), with the help of the slope and the limited slope angle, the motor under test (5) can roll on the guide rail (13) by itself relying on its own gravity.

[0024] 3. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com