Patents

Literature

78results about How to "No measurement error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Angle measurement precision detection apparatus of encoder and detection method thereof

InactiveCN102494710AMany measuring pointsShort measuring cycleUsing optical meansContinuous measurementObservational error

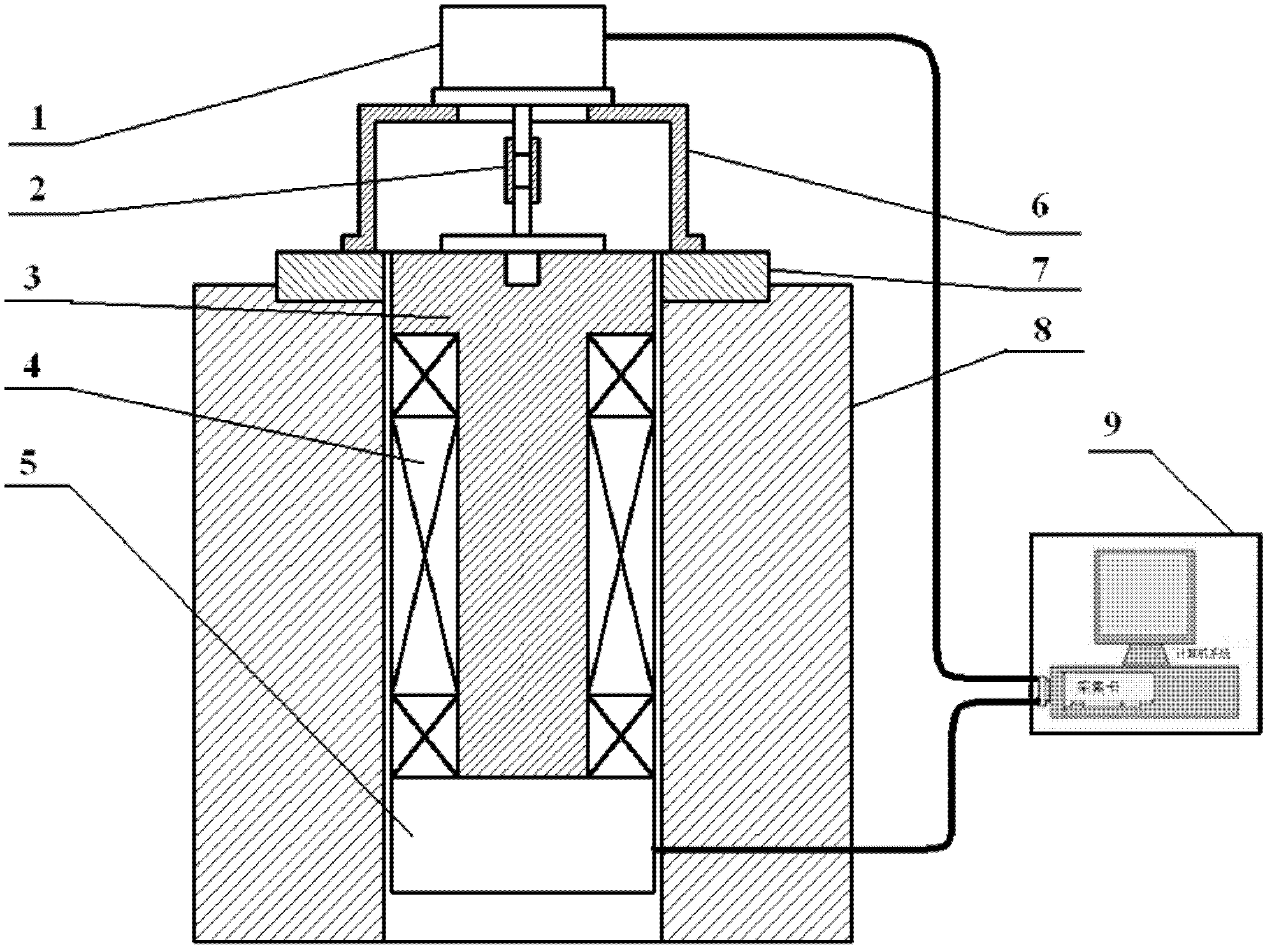

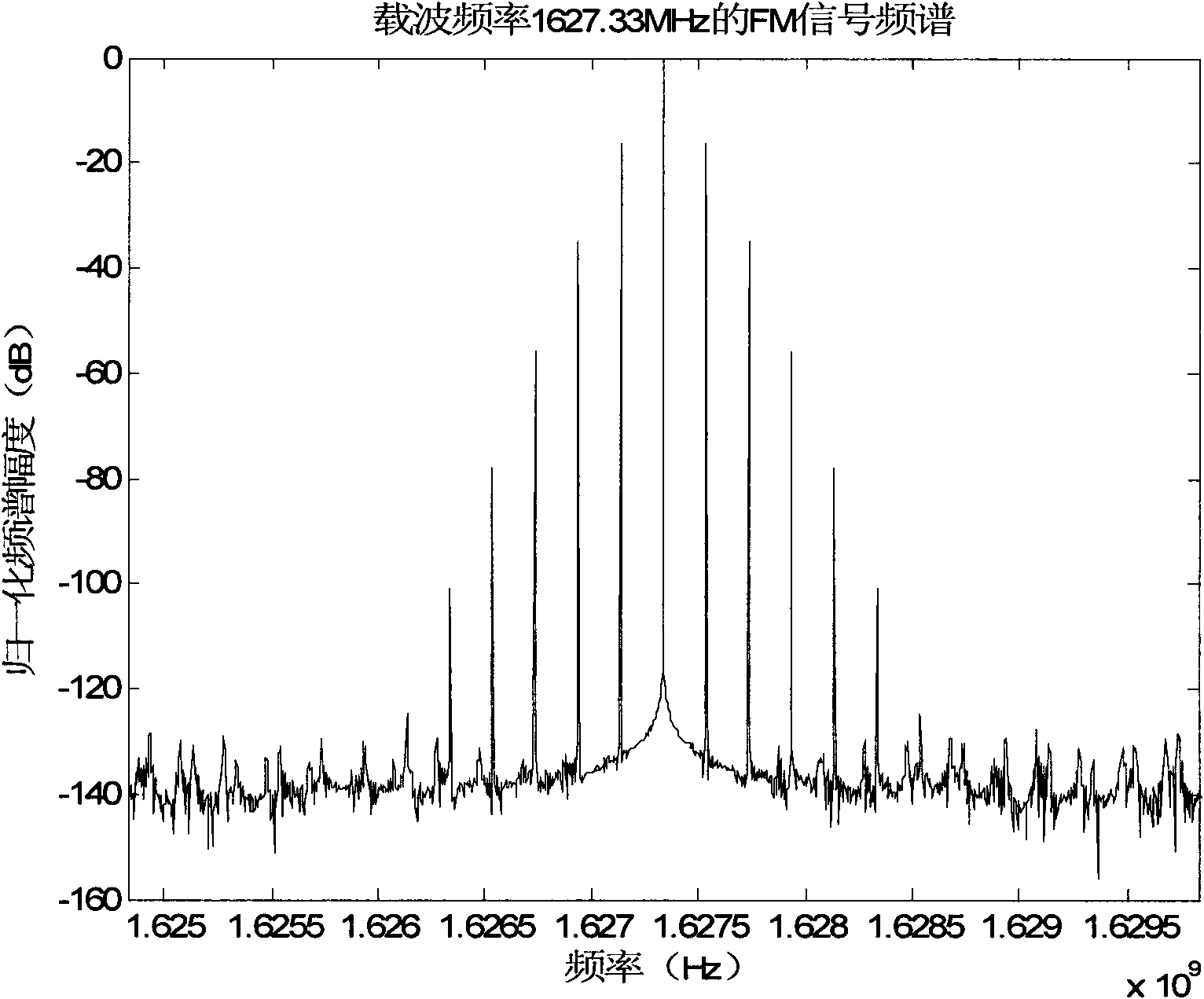

The invention relates to the precision shaft angle measuring instrument precision detection filed, more particularly to an angle measurement precision detection apparatus of an encoder and a detection method thereof. The apparatus comprises a coupling assembly, a precision main shaft, a motor, a precision encoder, a connection base, a rotary table, a workbench, and a computer system. The precision encoder is employed as a reference and is connected with the precision main shaft coaxially. The precision main shaft is driven by the motor; and an output shaft of the precision main shaft is connected with a detected encoder. The computer controls the rotating speed and the position of the motor as well as simultaneously collects angle measurement data of the precision encoder and the detected encoder; and an error value representing deviation of the position output of the detected encoder from the position output of a reference precision encoder is obtained in rotation angles from 0 degree to 360 degrees of the precision main shaft. And processing is carried out by the computer to provide various measurement errors of the detected encoder and error frequency spectrums. According to the invention, beneficial effects are as follows: there are lots of measurement points and measurement can be carried out continuously, so that various errors of a detected encoder can be reflected; a frequency spectrum analysis on an error source can be carried out; automatic measurement is carried out, the measuring period is short and efficiency is high; and electronization of data processing is realized as well as detection data are filed.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

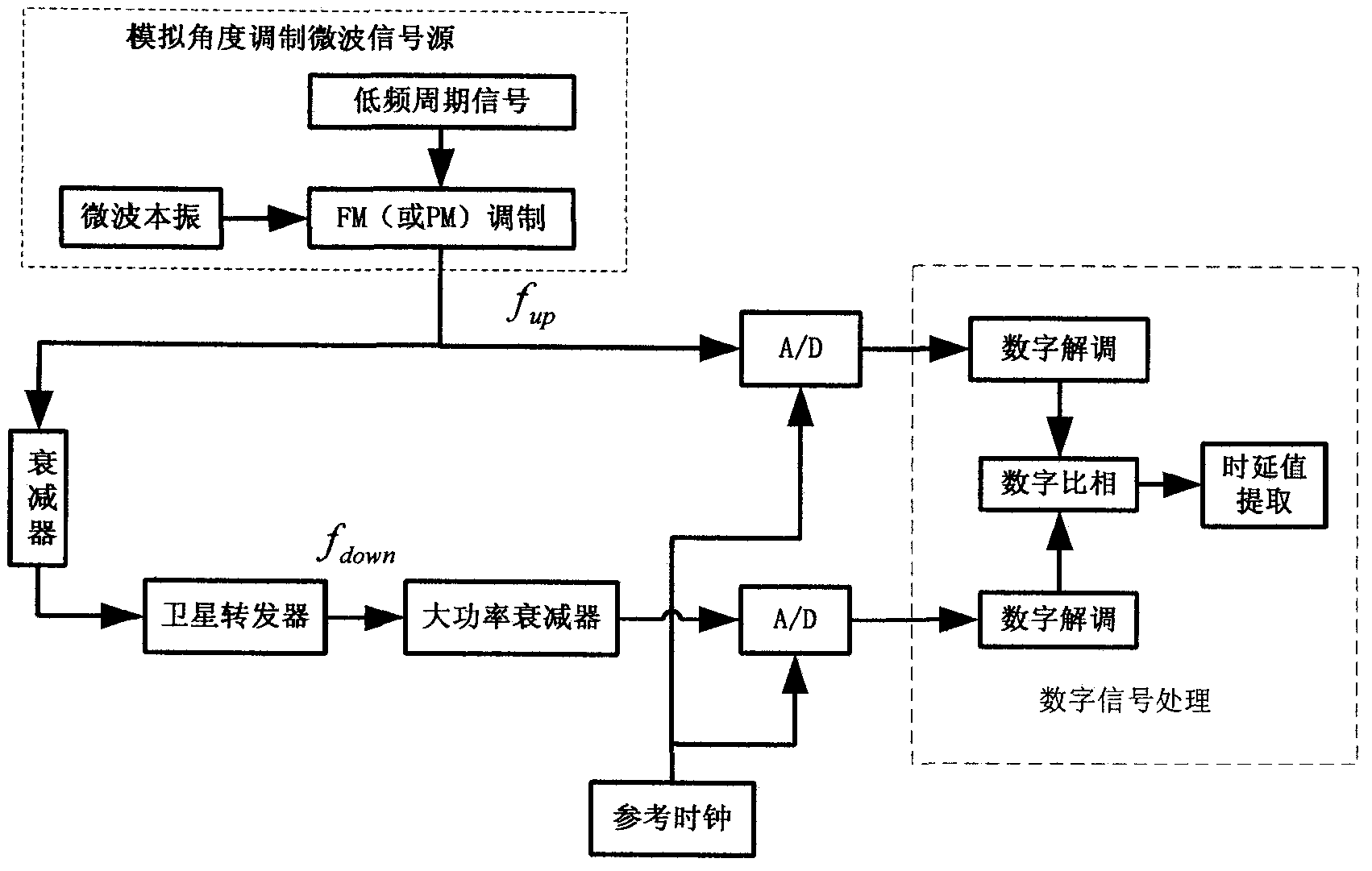

Frequency change system group delay test method

ActiveCN102325058AFlexible testingEasy to testData switching networksDigital down conversionCarrier signal

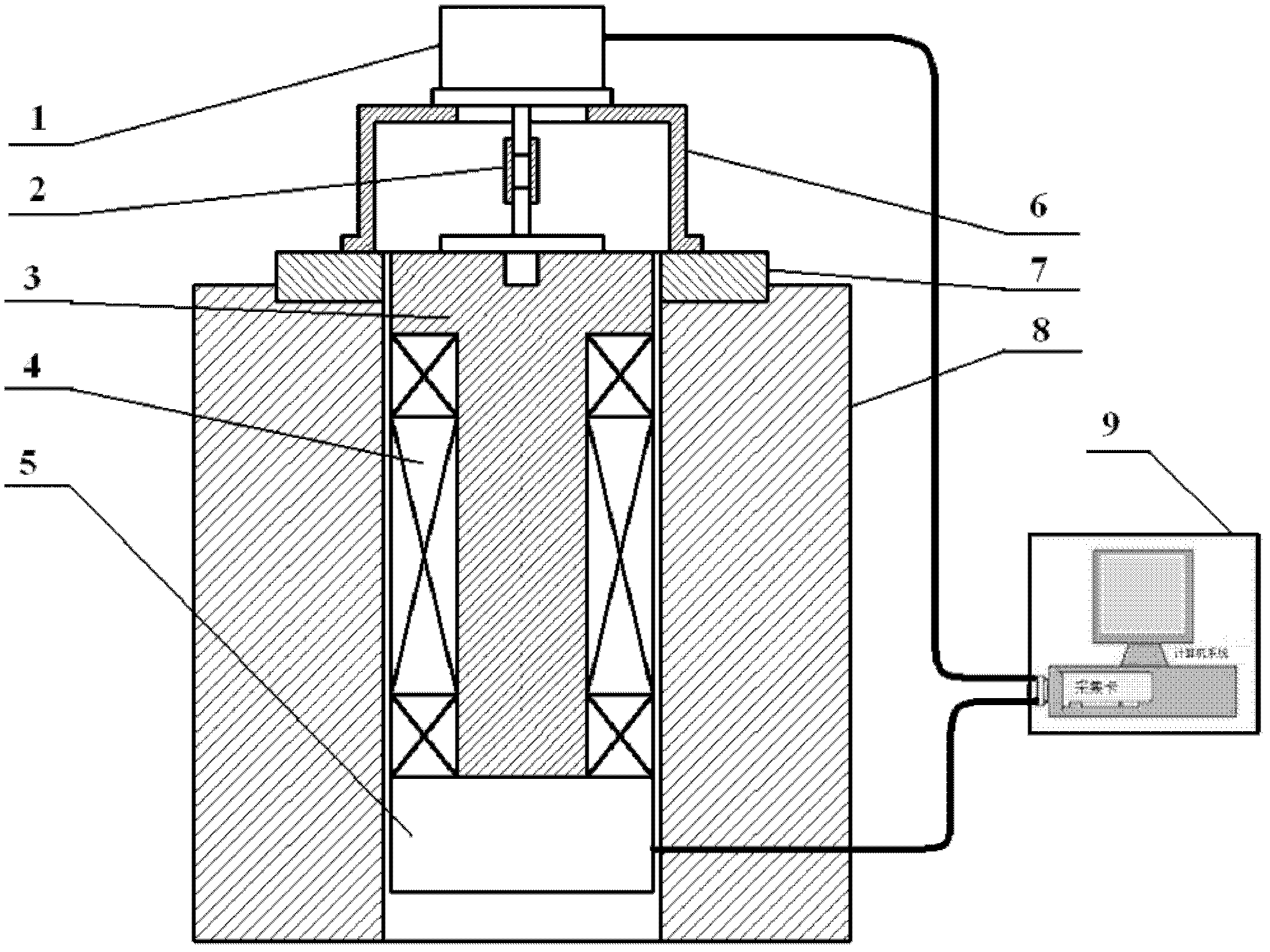

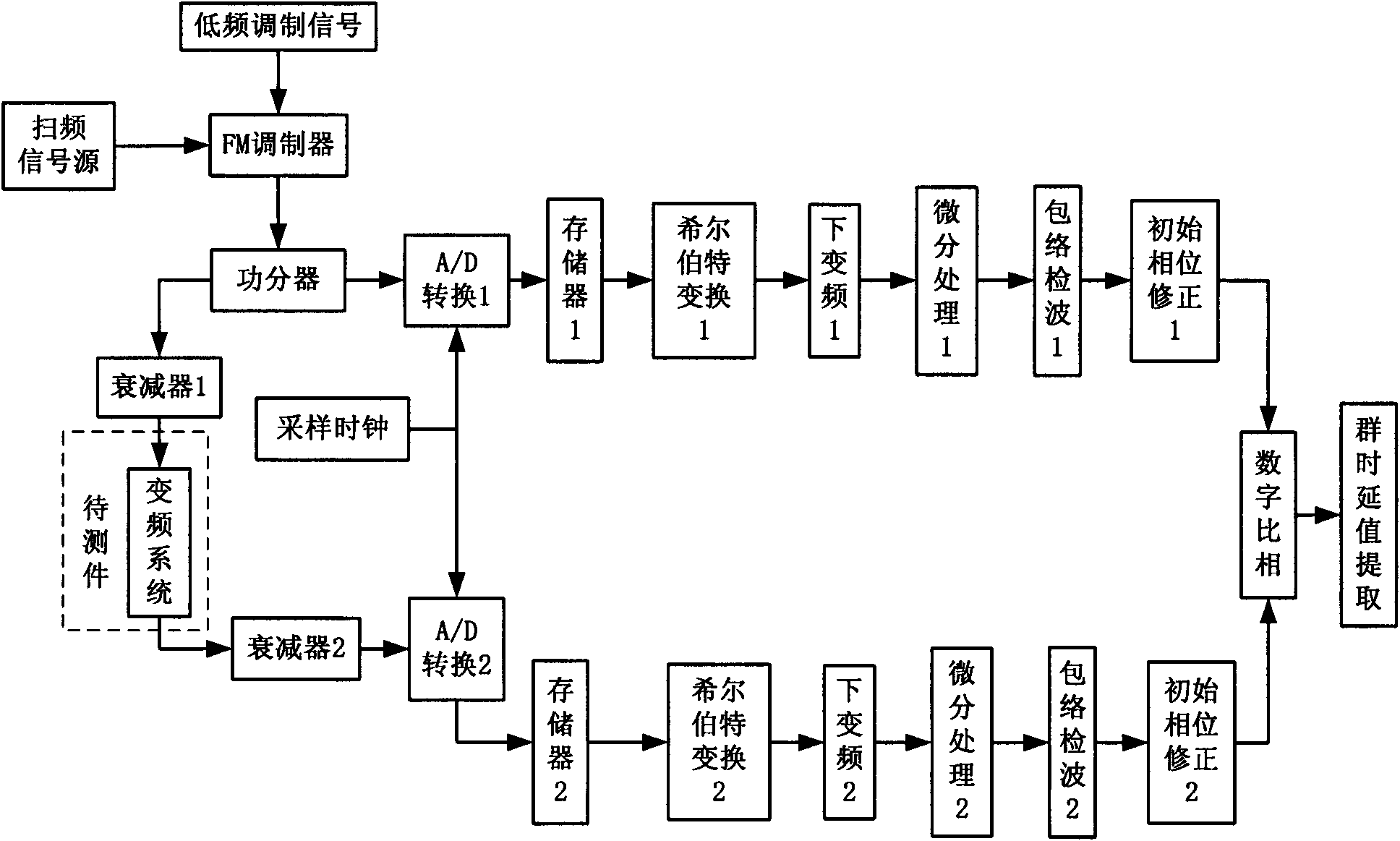

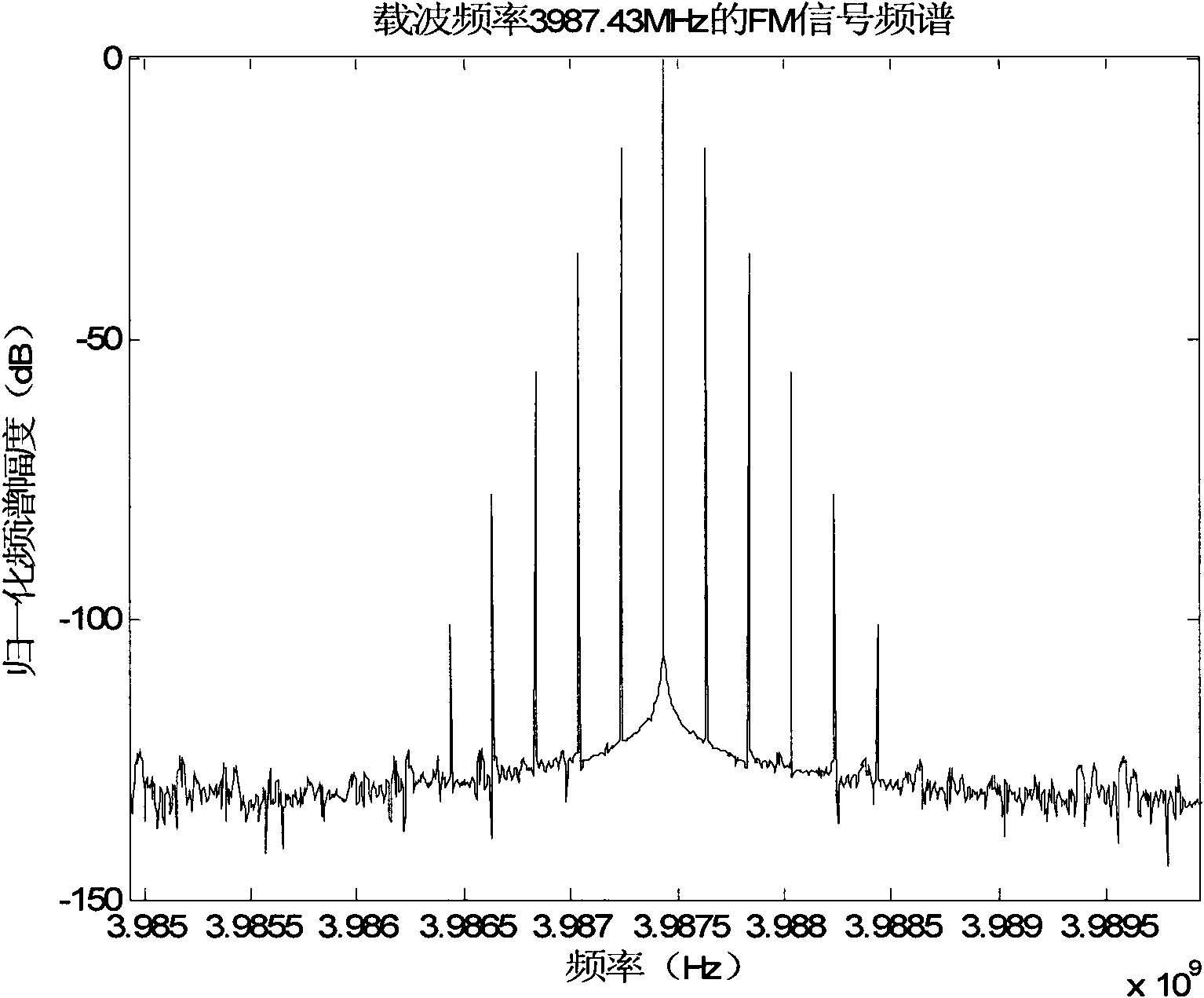

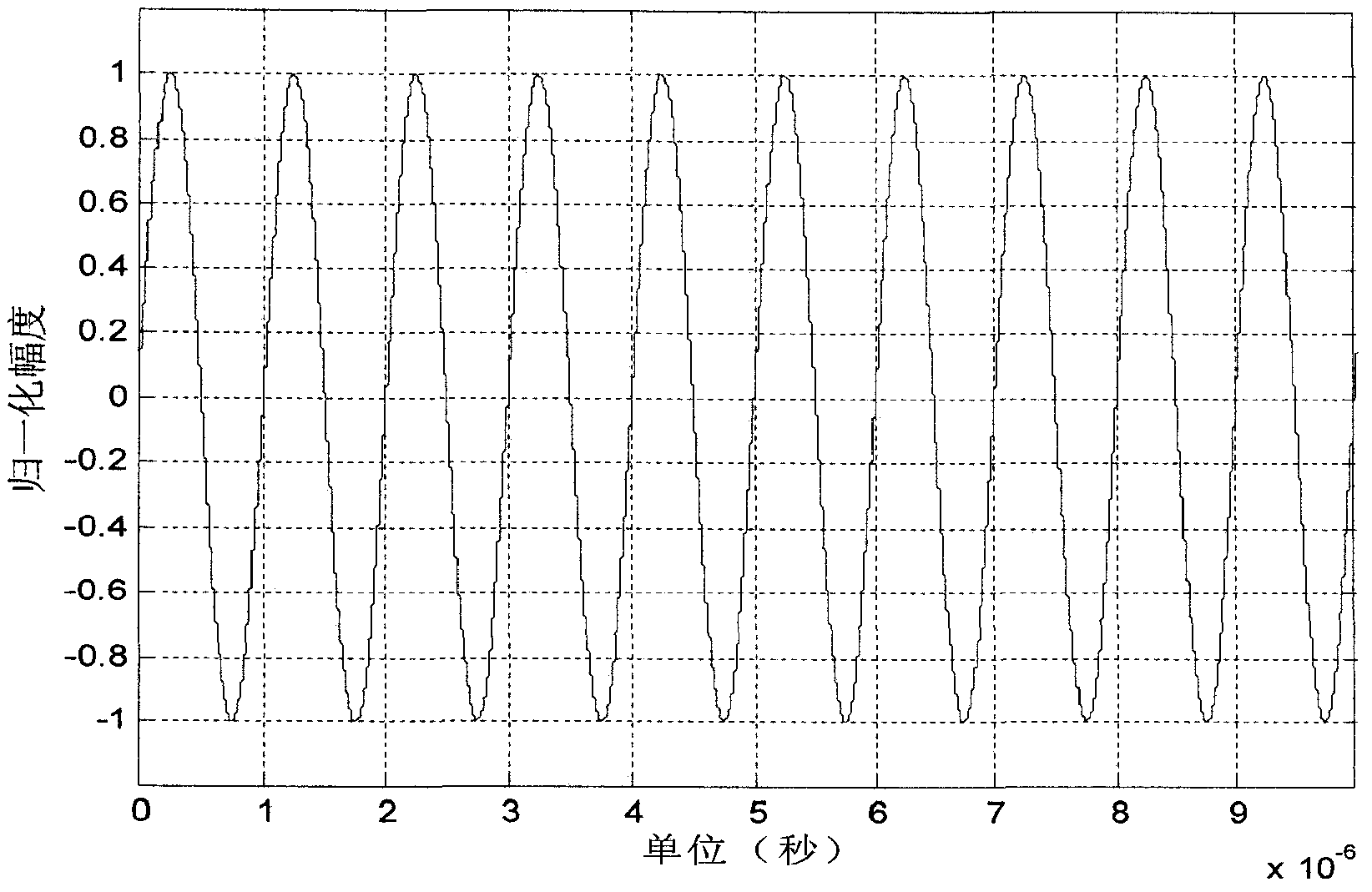

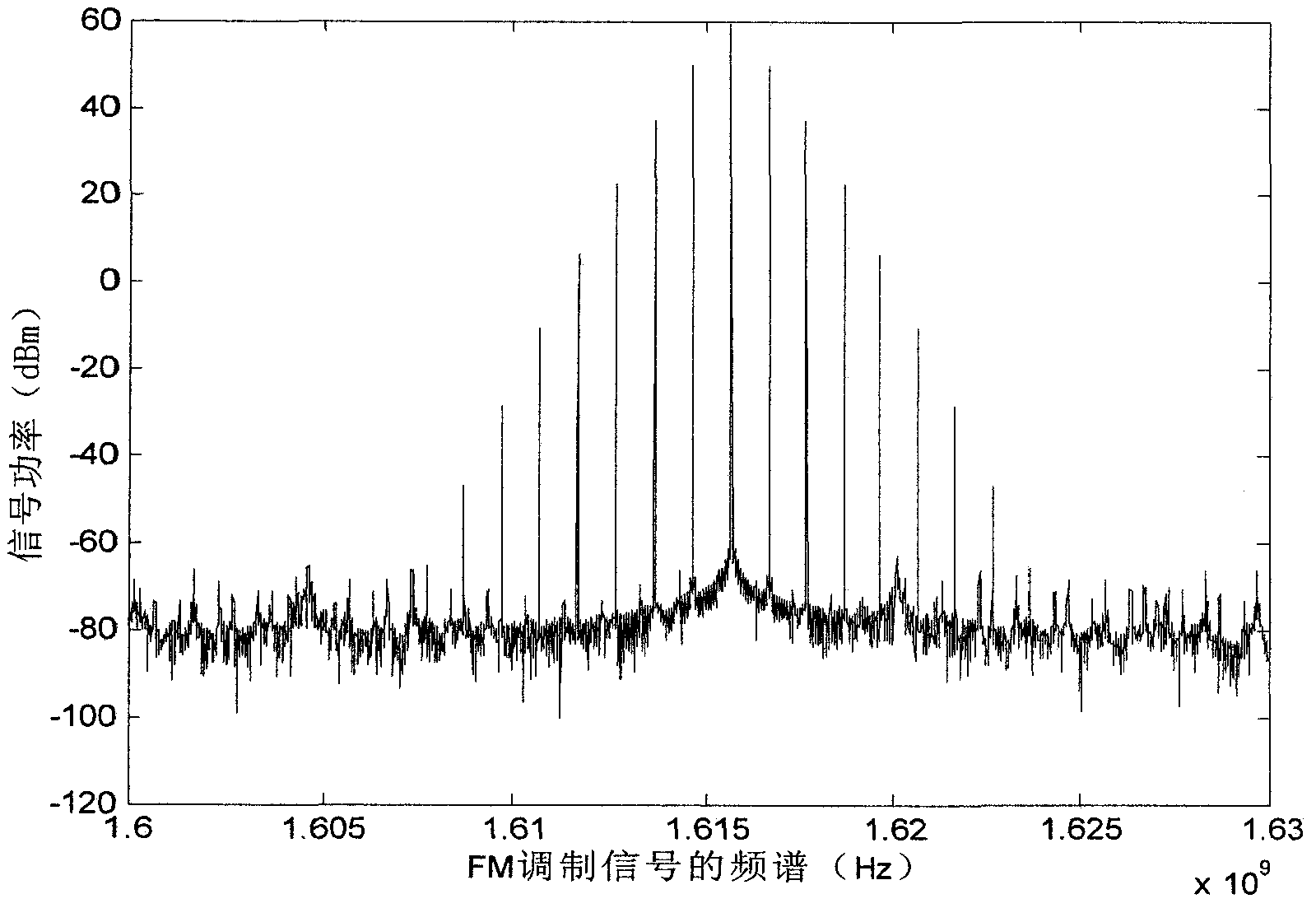

The invention relates to a frequency change system group delay test method which comprises the following steps of: generating an FM (Frequency Modulation) carrier signal of which the carrier frequency is the center frequency of a working frequency band of a frequency change system by a signal source; then dividing the signal into two paths, wherein one path of signal is input to the frequency change system by an attenuator and used as the input of a first A / D (Analog-to-Digital) converter by the attenuator after being output by the frequency change system, the other path of signal is used as the input of a second A / D converter, and the two A / D converters synchronously sample data by using the same reference clock; then respectively carrying out Hilbert transformation, digital down conversion and non-coherent demodulation on two paths of A / D sampled data; and carrying out digital phase comparison on the two paths of demodulated base band signals to obtain a group delay value of the frequency change system. A group delay test result of all frequency points of the frequency change system in the frequency band can be obtained by changing the carrier frequency of the FM carrier signal in the working bandwidth of the frequency change system and repeating the processing; and the measuring precision depends on system heat noise, the correcting precision of a test cable and A / D sampling resolution.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

Method for calibrating verticality of magnetic shaft of three-shaft magnetic sensor

ActiveCN102853760ANo measurement errorNo errorUsing electrical meansMagnitude/direction of magnetic fieldsCalibration resultMagnetic axis

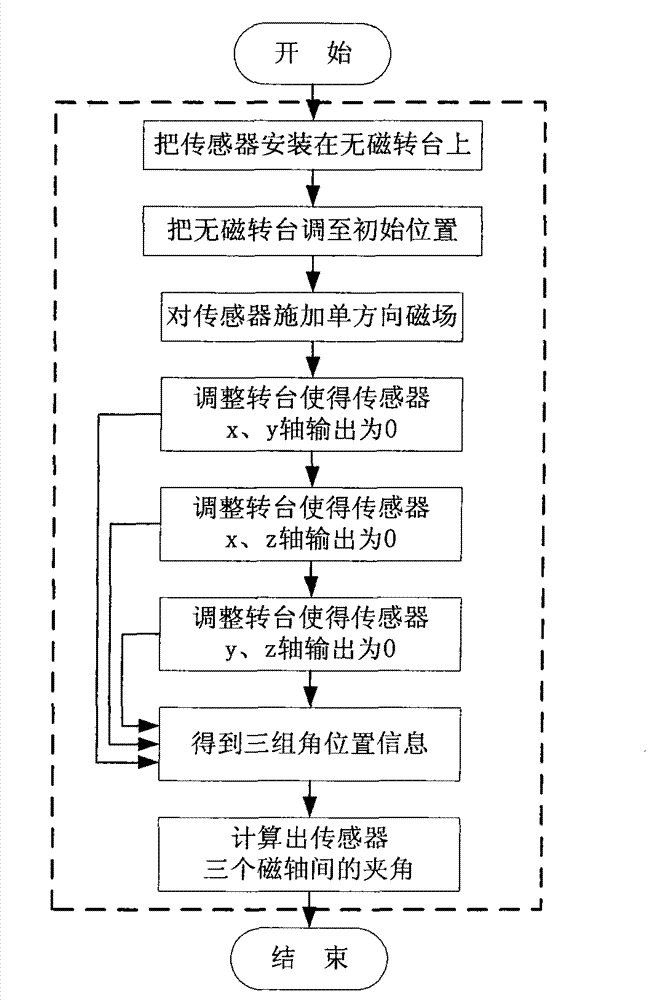

The invention discloses a method for calibrating verticality of a magnetic shaft of a three-shaft magnetic sensor. A three-dimensional magnetic field generator and a nonmagnetic rotary table are adopted, the three-dimensional magnetic field generator and the nonmagnetic rotary table are arranged at first; the magnetic sensor which needs to be calibrated is fixed on the rotary table; a large magnetic field ranging from top to bottom is generated by the magnetic field generator, so that a numeric value measured by the sensor is not zero; the zero position of the rotary table is marked, the angle values of three shafts of the rotary table are recorded, and three shafts of the rotary table are rotated, so that the outputs of a shaft m and a shaft n of the sensor are zero and the angle values of the three shafts of the rotary table are recorded; the three shafts of the rotary table are rotated again, so that the outputs of a shaft m and a shaft n of the sensor are zero and the angle values of the three shafts of the rotary table are recorded; transformation relation between each shaft m, n and p of a coordinate O and each shaft x3y3z3 of the coordinate O3 can be obtained by calculating multiple recorded angle values so as to obtain a calibration result. The method is simple and feasible, high in accuracy and small in errors.

Owner:HARBIN INST OF TECH

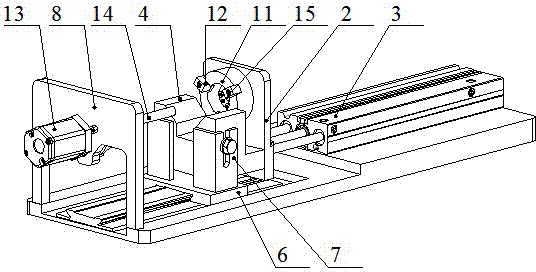

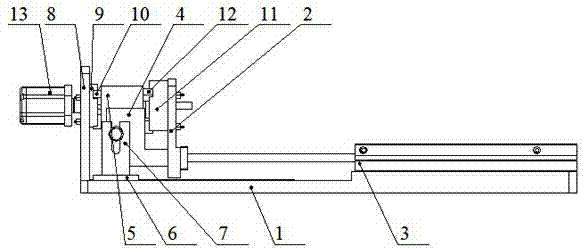

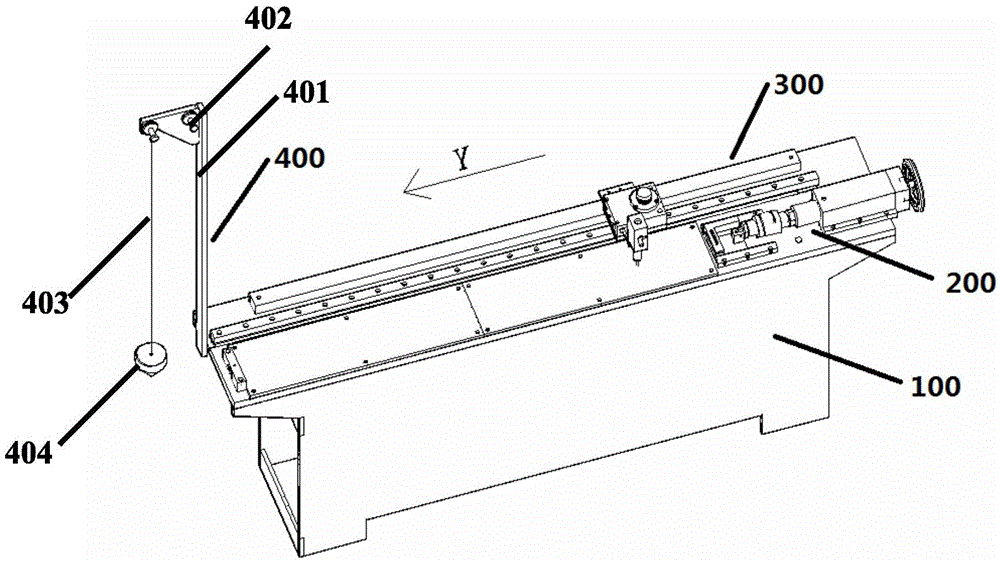

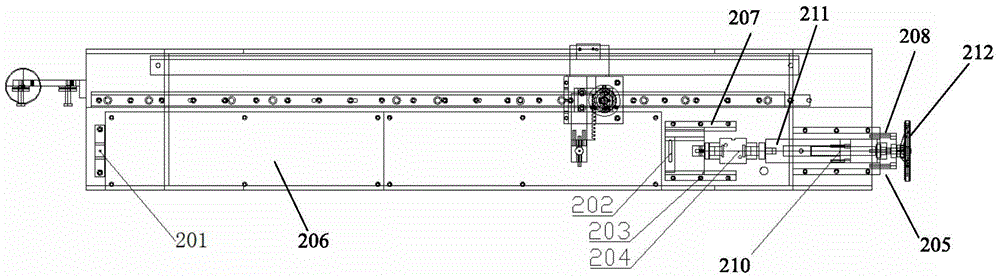

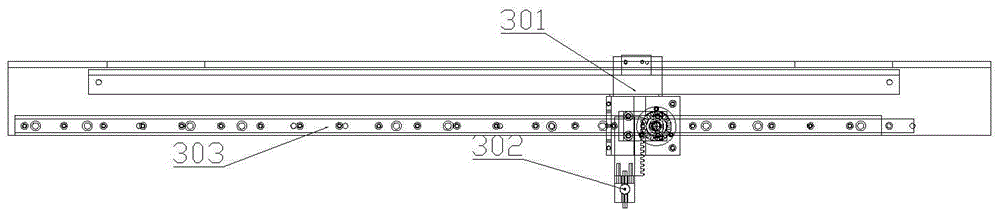

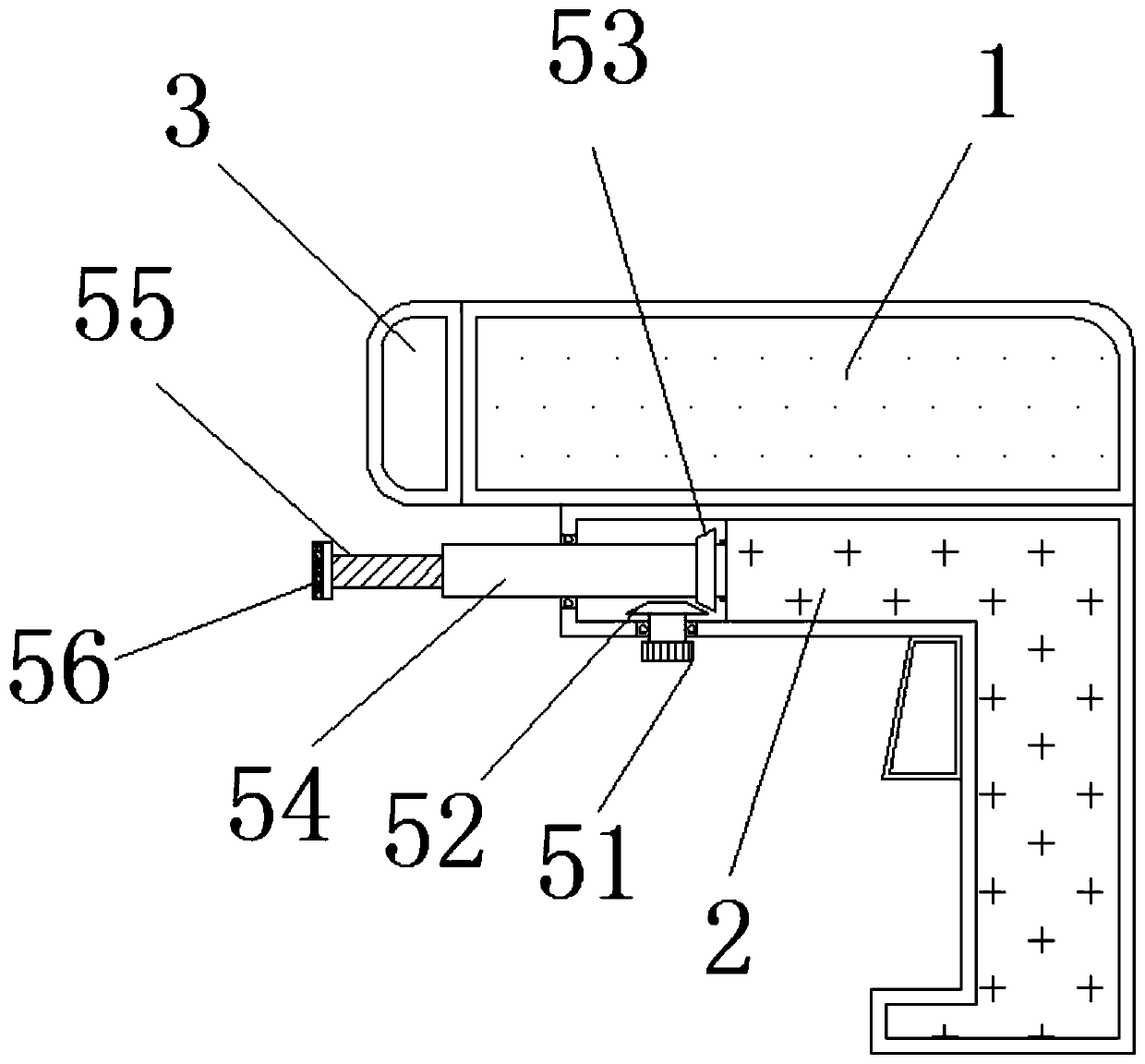

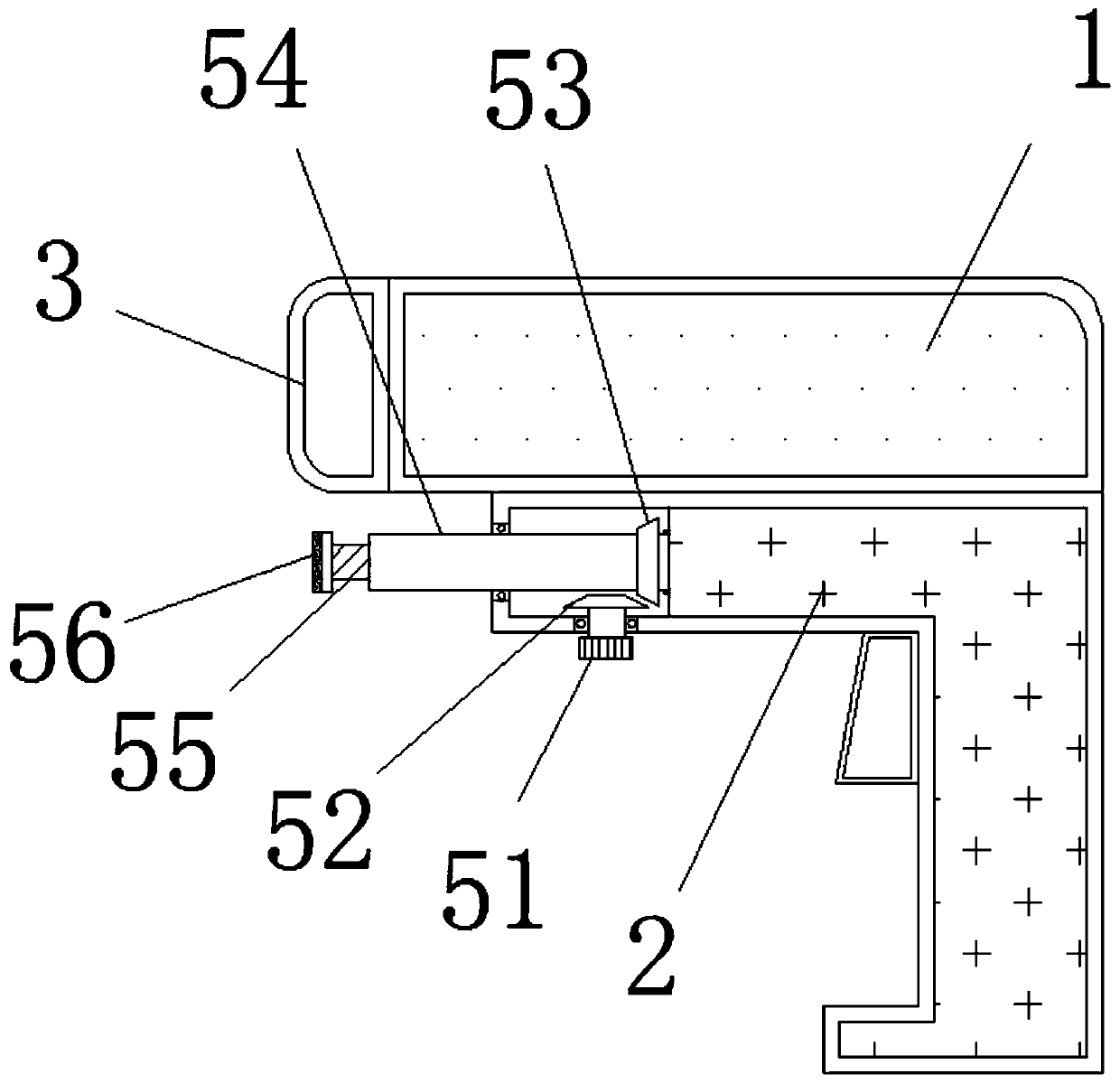

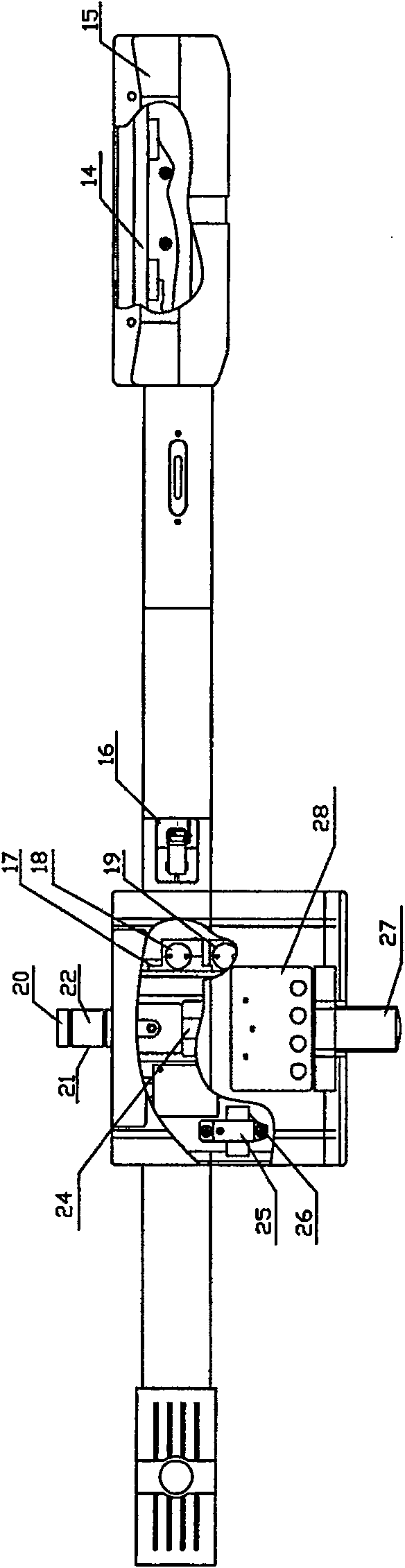

Automatic length measuring device for sleeve parts

ActiveCN104515489ARealize automatic online detectionIncrease the degree of automation of length measurementMeasurement devicesObservational errorProduction line

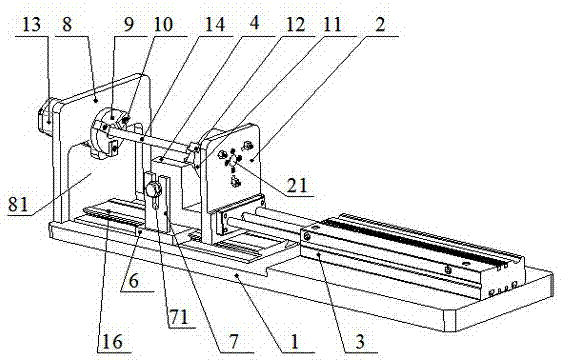

The invention discloses an automatic length measuring device for sleeve parts, comprising a clamping mechanism, a positioning mechanism and a measuring mechanism. The automatically sleeve-type part length measuring device is applicable to an automatic flow production line of sleeve-type parts, effective in automatic on-line detection and easy to produce and functions in improving automation of the sleeve-type part length measurement, leading to no manual measuring errors and reliable and stable measuring result, and accordingly measuring efficiency is greatly improved; a non-contact sensor serves as a length measuring apparatus to rapidly and stably measure, without abrasion; a cylinder is matched with a dovetail slot guide rail, leading to high linear movement precision, thus coaxiality of an induction magnetic ring and an induction rod is maintained within a reasonable range, and measurement is smoothly performed with high precision.

Owner:SUZHOU ZIJINGANG INTELLIGENT MFG EQUIP

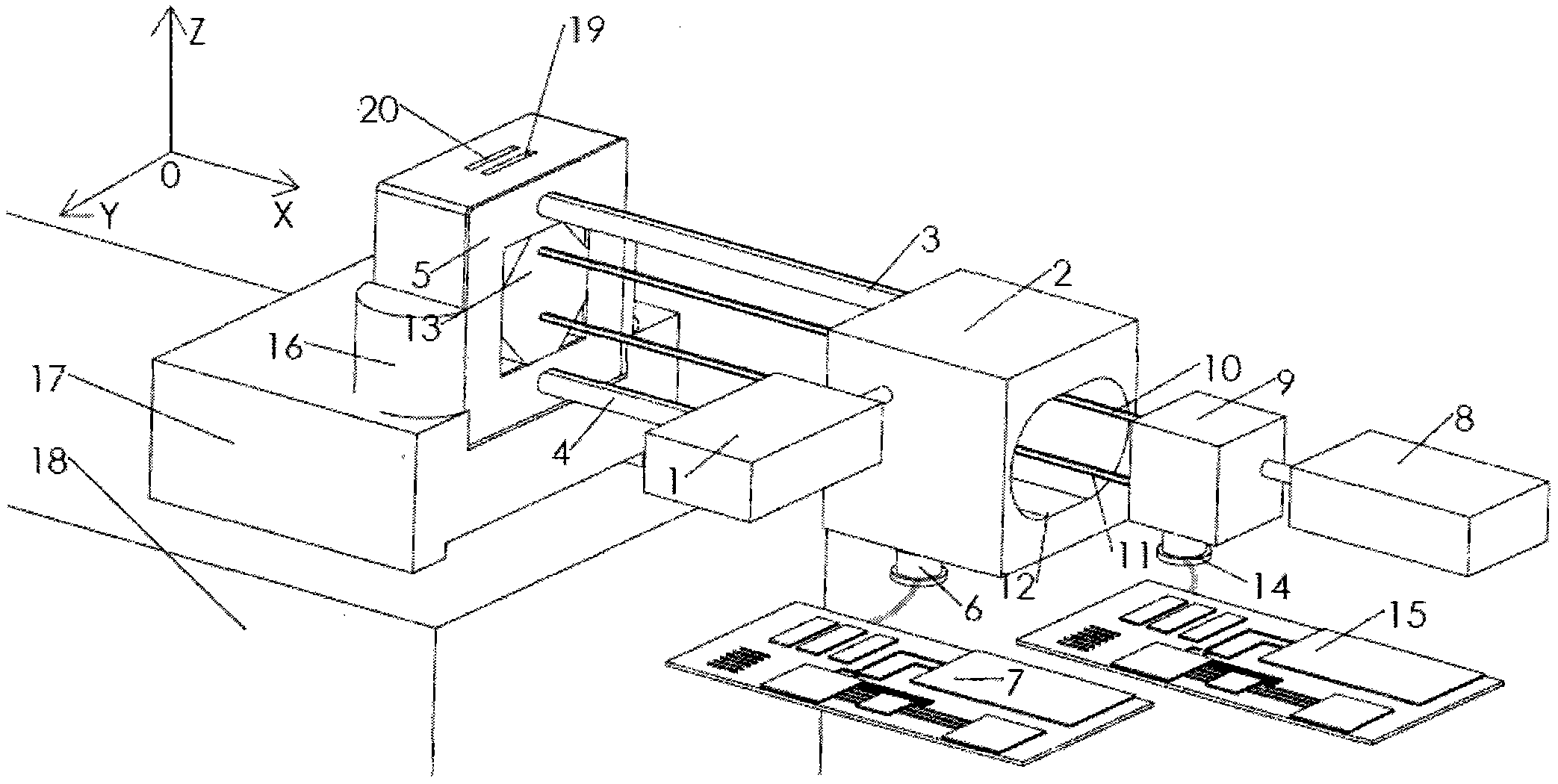

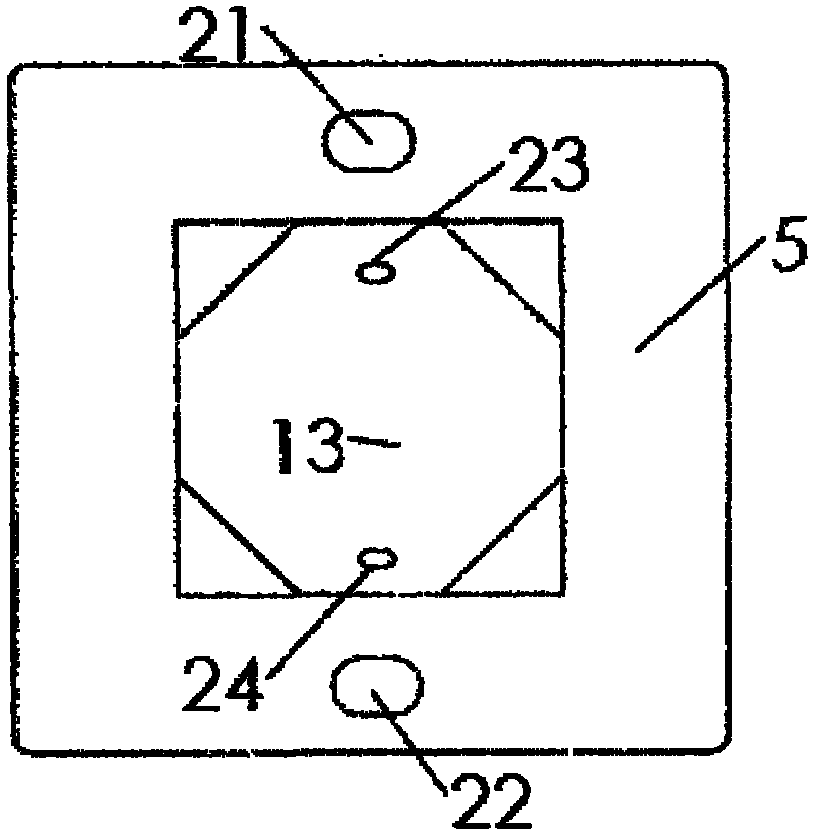

Micron-nano grade three-dimensional measurement '331' system and measurement method thereof

InactiveCN101419044AAvoid Abbe errorNo measurement errorMechanical measuring arrangementsMicro nanoThree dimensional measurement

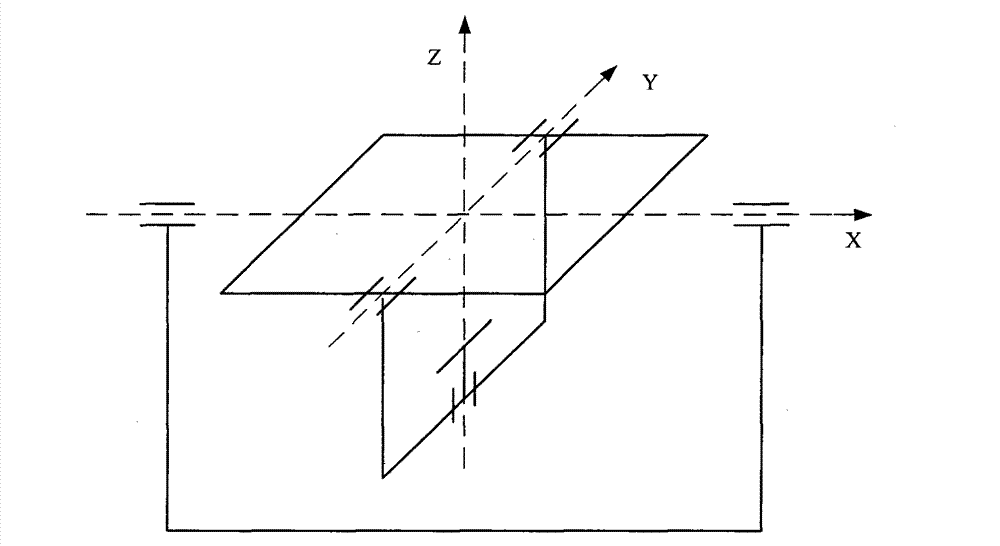

The invention provides a micro-nano level 3-D measurement '331' system and a measurement method thereof. The system is characterized in that X, Y and Z-axis standard-measure dimension lines or extended lines thereof of the 3-D measurement system are arranged to be perpendicular to one another and intersect at one intersection point, so as to establish a 3-D coordinate system taking the intersection point as a coordinate origin; an X-axis guide-rail guide plane and a Y-axis guide-rail guide plane of a measurement platform in the measurement platform are arranged to be coplanar with a measurement plane where a measuring-head central point is, so as to form a coincidence plane; the intersection point of the X, Y and Z-axis standard-measure dimension lines or the extended lines thereof is on the coincidence plane of the measurement platform; meanwhile, the X and Y-axis standard-measure dimension lines or the extended lines thereof are also arranged to coincide with three planes, so as to ensure that X and Y coordinate planes of the established coordinate system coincide with the measurement plane; and the measuring-head central point is arranged to coincide with the intersection point of the three standard-measure dimension lines or the extended lines thereof. The invention satisfies the Abbe principle in 3-D direction, thereby effectively avoiding Abbe errors and guaranteeing high measurement precision.

Owner:HEFEI UNIV OF TECH

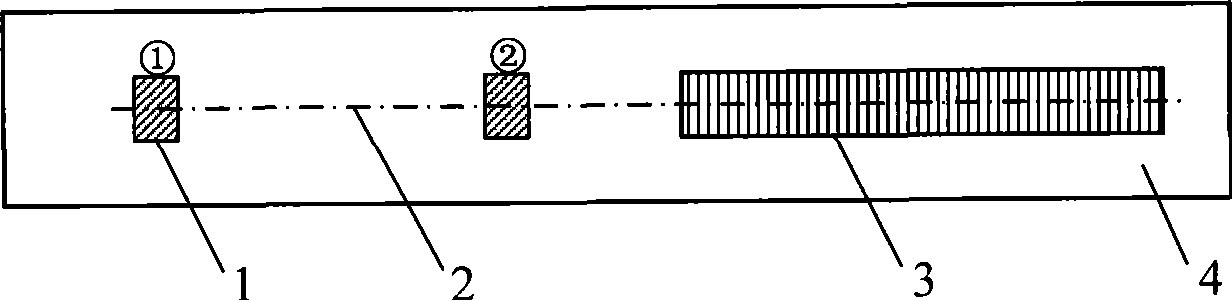

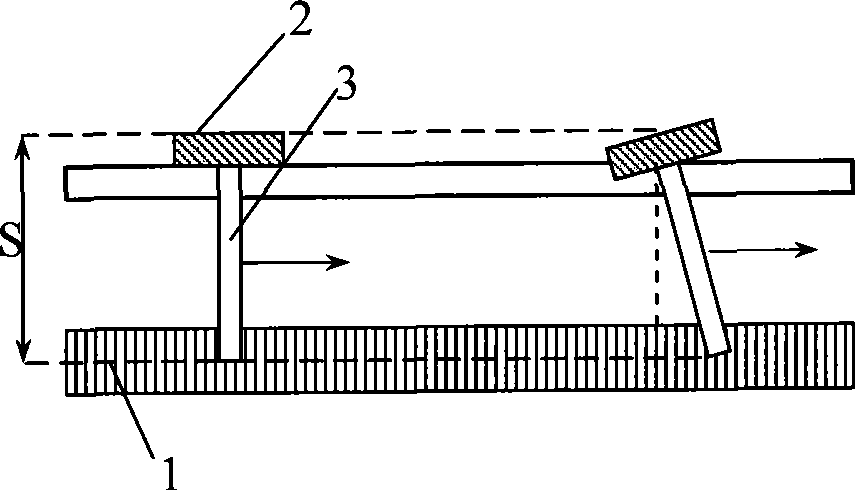

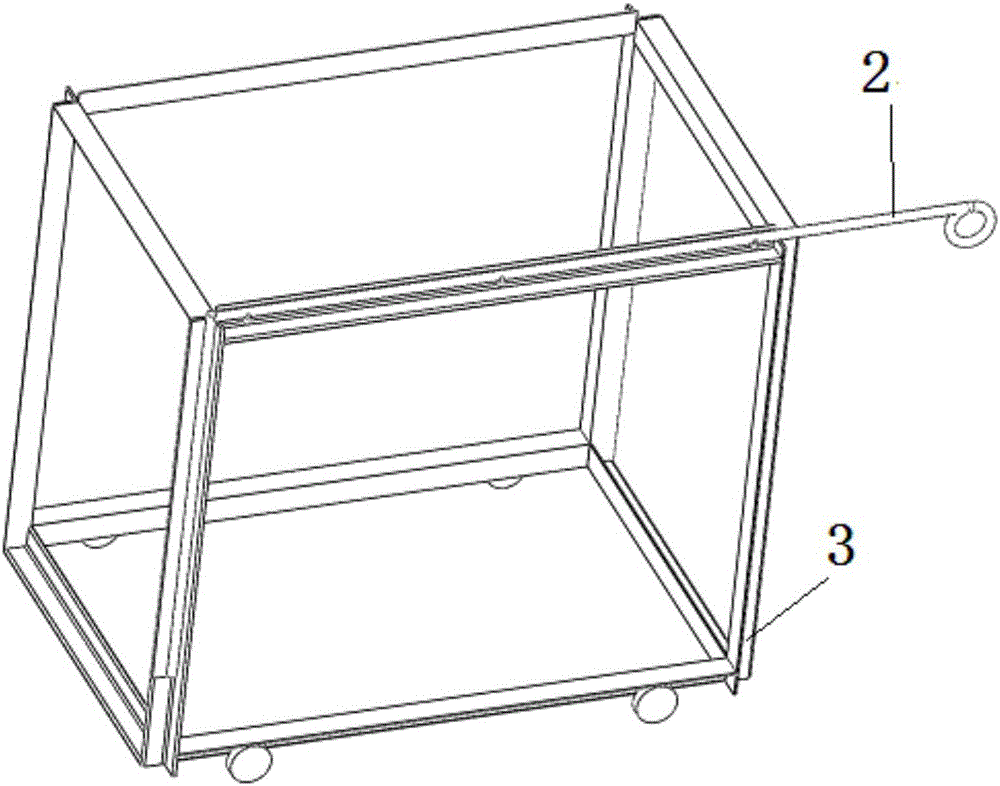

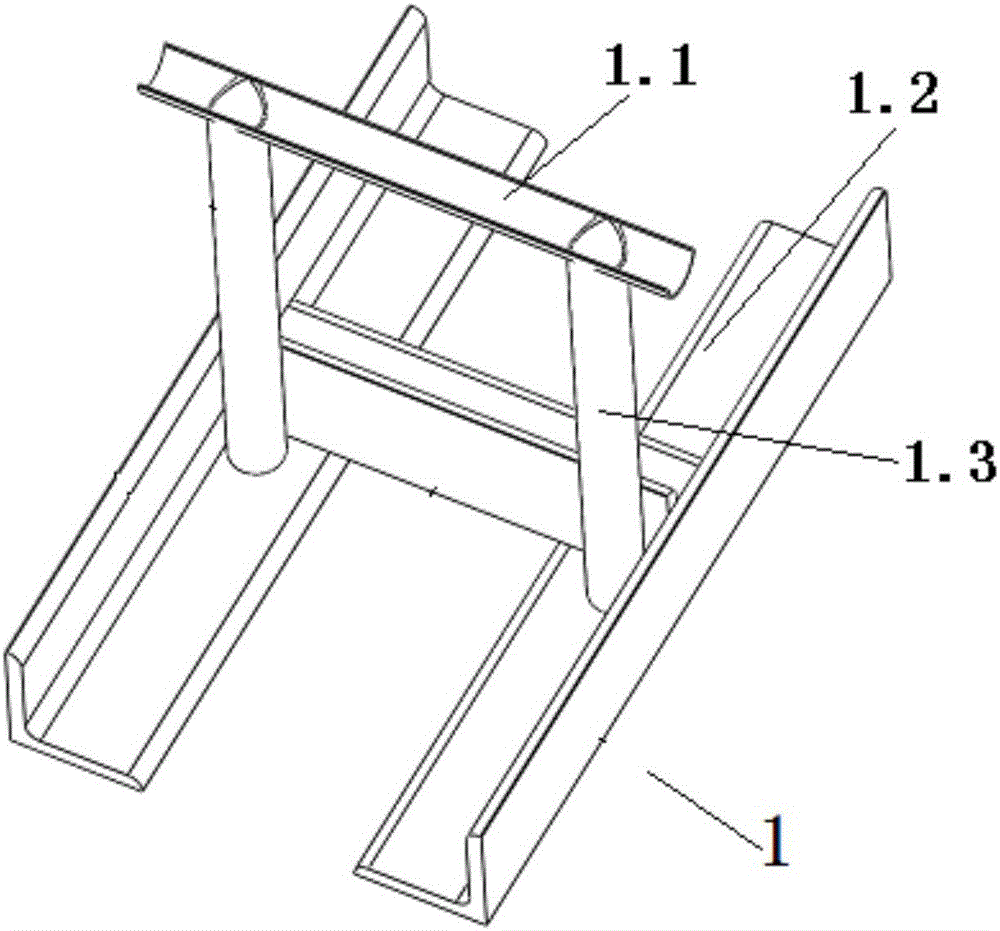

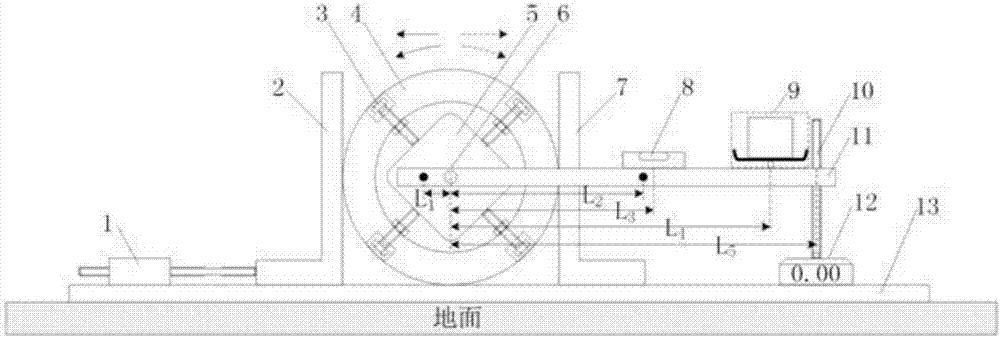

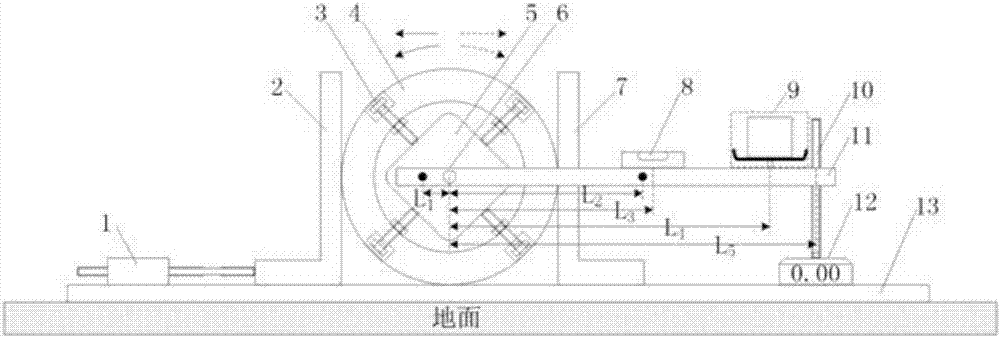

General chain length extension detection device

InactiveCN105547164AGuaranteed parallelEasy to operateMachine part testingUsing optical meansGratingChain length

The present invention discloses a general chain length extension detection device. The device comprises a workbench, a pulley block arranged on the workbench, a pulling assembly and a measurement assembly. The pulley block is arranged at one side face of the workbench, the measurement assembly is arranged on the surface of the workbench and in the same horizontal line as the pulley block, and the pulling assembly is arranged on the surface of the workbench and is in parallel with the measurement assembly. The general chain length extension detection device replaces a traditional manual detection mode, is able to detect multiple chains and has universality; and moreover, a grating ruler is taken as a measurement instrument, so that the measurement error is greatly reduced, the operation is simple and only one person is able to operate.

Owner:SUZHOU CHUNMENG INTELLIGENT TECHNOLOGY CO LTD

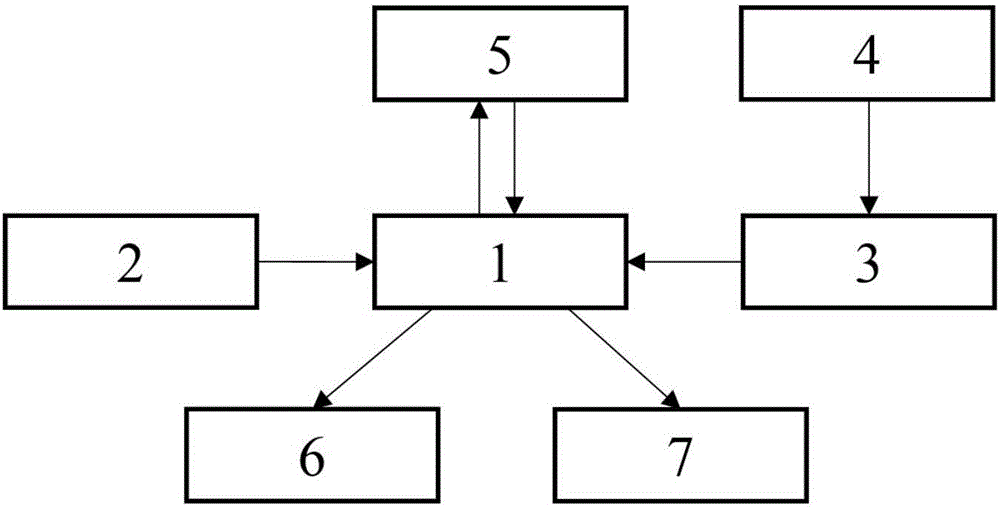

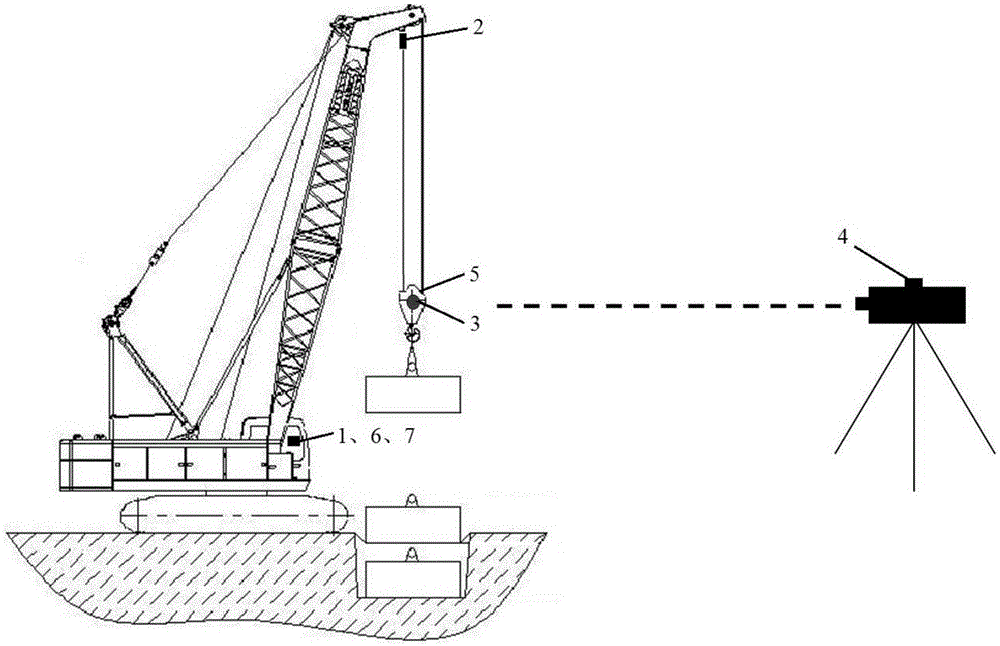

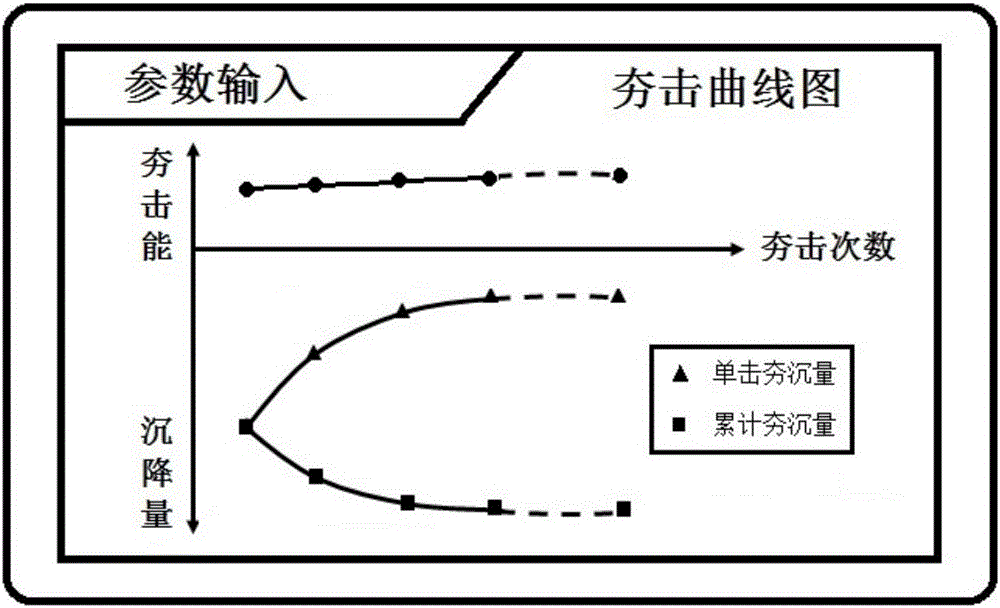

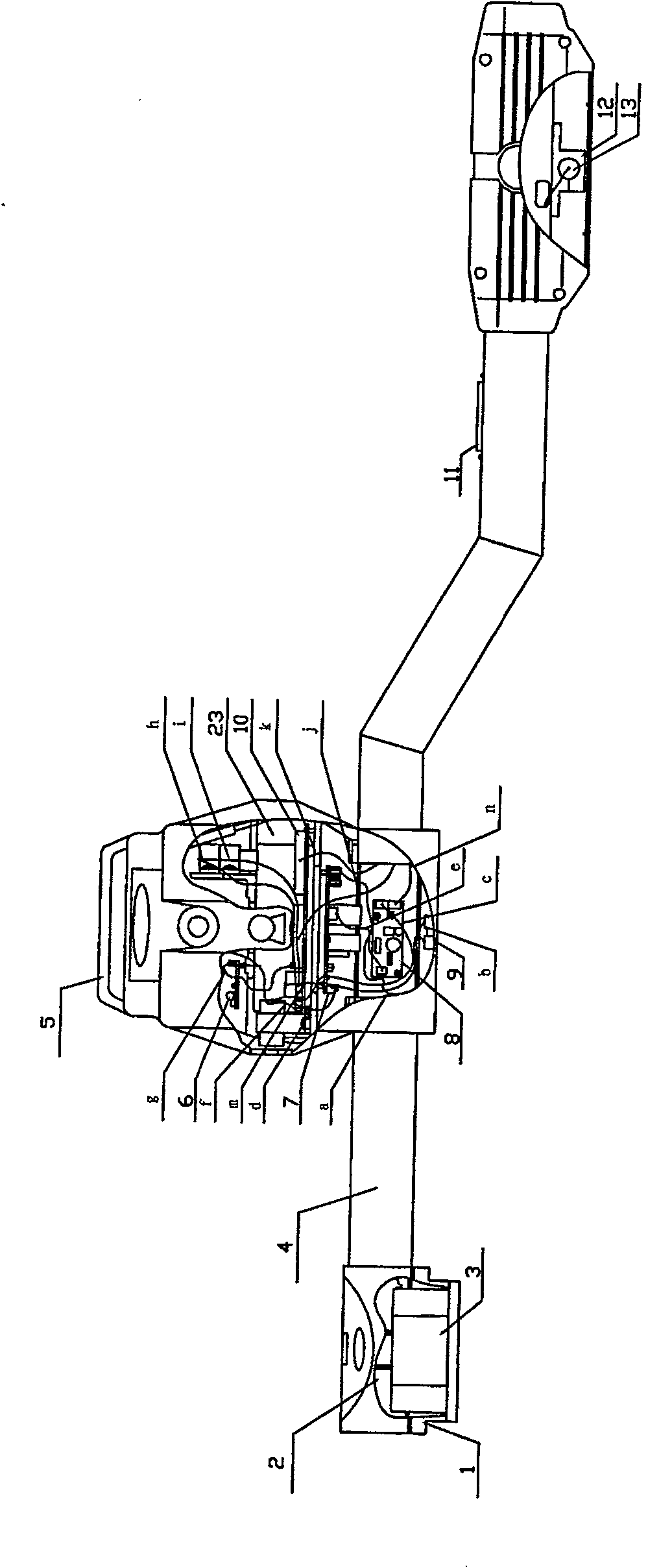

Dynamic compaction machine construction and operation parameter acquiring system and operating method thereof

ActiveCN106500770ASave human effortLow costMeasurement devicesSoil preservationProgrammable logic controllerReal time display

The invention comprises a dynamic compaction machine construction and operation parameter acquiring system and an operating method thereof. The dynamic compaction machine construction and operation parameter acquiring system is characterized in that: a programmable logic controller PLC is connected with a signal receiving device, an optical encoder, a tension sensor, a buzzer and a display, and the signal receiving device communicates with a signal transmitting device; the optical encoder is connected with a pulley above a pounder hammer hook, and the tension sensor is connected with a steel wire rope; and the signal transmitting device is arranged outside a dynamic compaction influence range and is leveled, and is aligned with a dynamic compaction machine. The dynamic compaction machine construction and operation parameter acquiring system and the operating method thereof have the beneficial effects that precise acquisition and dynamic real-time display of tamping settlement, accumulated tamping settlement, pounder hammer weight, falling distance and tamping energy data can be realized, the detection result cannot generate measurement errors due to the influence of factors such as sagging of the dynamic compaction machine.

Owner:SHANDONG UNIV

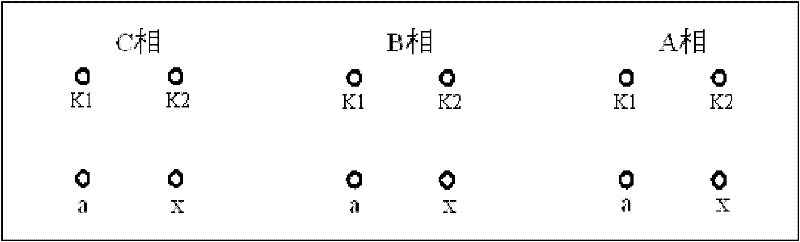

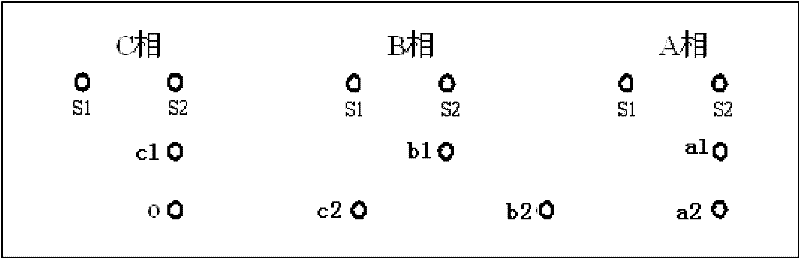

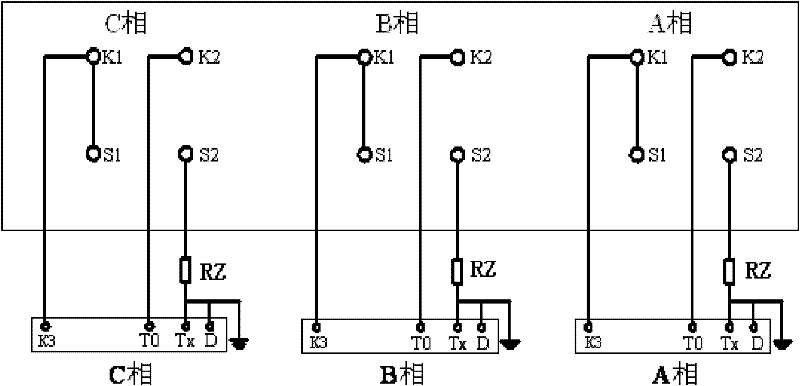

Integration wiring apparatus used for high voltage three-phase combination mutual inductor on-site detection

InactiveCN102393477ARealize secondary wiring connectionAvoid safety accidentsMeasurement instrument housingAviationEngineering

The invention provides an integration wiring apparatus used for high voltage three-phase combination mutual inductor on-site detection. When carrying out overall detection work of a high voltage three-phase combination mutual inductor, a secondary output terminal of a detected current transformer or a detected voltage transformer is directly inserted into a corresponding socket on an integration wiring apparatus panel, and a secondary output terminal of a standard current transformer or a standard voltage transformer is directly inserted into a corresponding socket on an integration wiring apparatus panel simultaneously. In a wiring apparatus, connection between a detected piece and a standard piece, and connection between a detected piece and a secondary detection circuit between mutual inductor check meters are realized, and through an aviation socket and an aviation plug, a corresponding detection terminal is directly connected to a high voltage three-phase combination mutual inductor, a three-phase mutual inductor check meter and a three-phase burden box. Thus on-site wiring is clear, work efficiency is raised, labor intensity is reduced, and security of detection work is ensured.

Owner:STATE GRID SICHUAN ELECTRIC POWER CORP ELECTRIC POWER RES INST +1

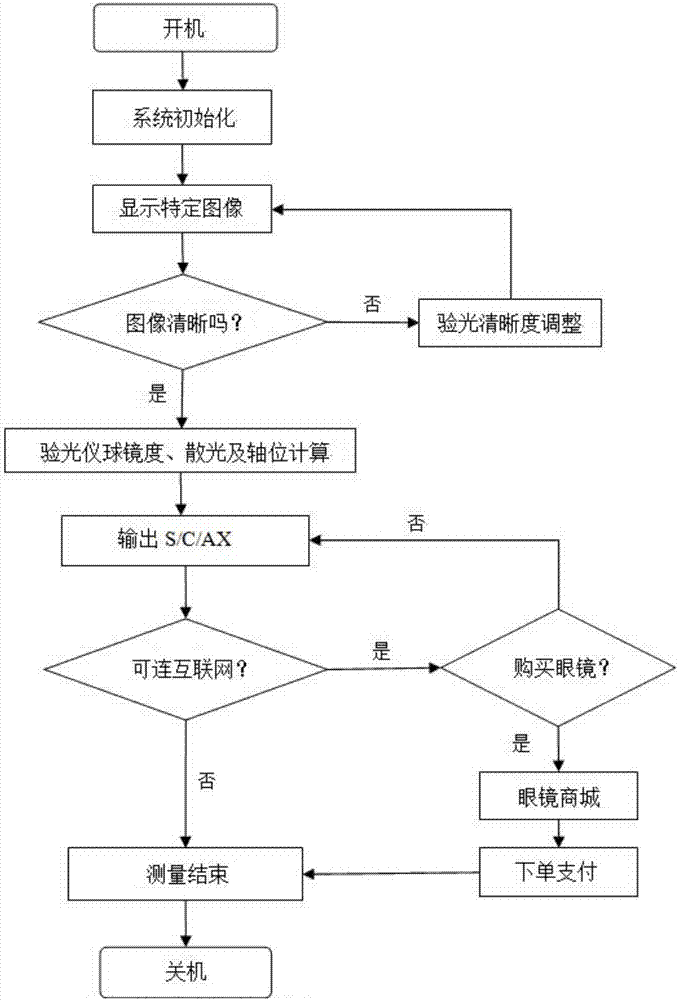

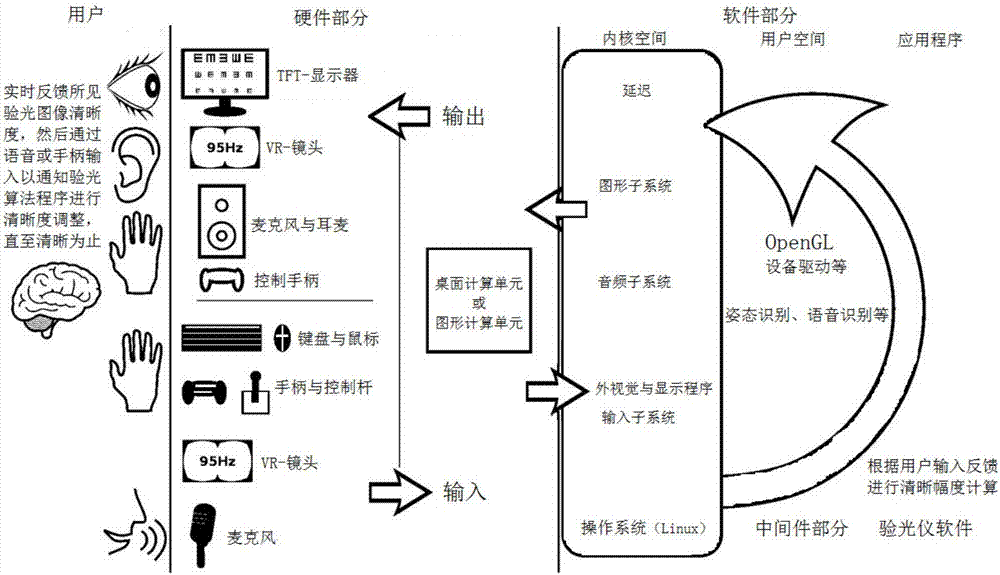

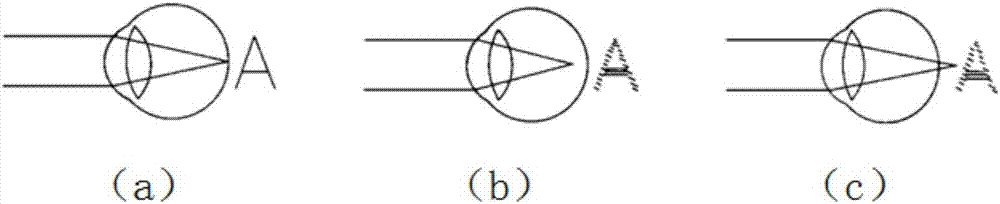

Optometry method based on VR technology and VR spectacle optometer

ActiveCN106963334AFast and convenient self-service optometryEasy to operateInput/output for user-computer interactionPhoroptersThe InternetSelf-service

The invention discloses an optometry method based on the VR technology and a VR spectacle optometer, and belongs to the technical field of optometry. The optometry method based on the VR technology comprises the following steps that (a) dedicated optometry images are established in a VR system, and a relation y=f(x) which is between a sharp image location x observed by human eyes and human eye power y is fit after sampling; (b) the image sharpness is adjusted through the adjustment of the image location by a user till a sharp image is observed; (c) cumulative image location information is recorded by an optometry algorithm, and the human eye power is calculated through the relation fit in step (a). The invention further discloses the VR spectacle optometer. The optometry method is simple, easy, reliable and stable, while the VR spectacle optometer has the advantages of light weight, convenience, easy mobility and low cost, and spectacles can be prescribed and bought in a self-service mode through the Internet, which is used with convenience.

Owner:SHANGHAI ZHANZHI OPTICAL INSTR

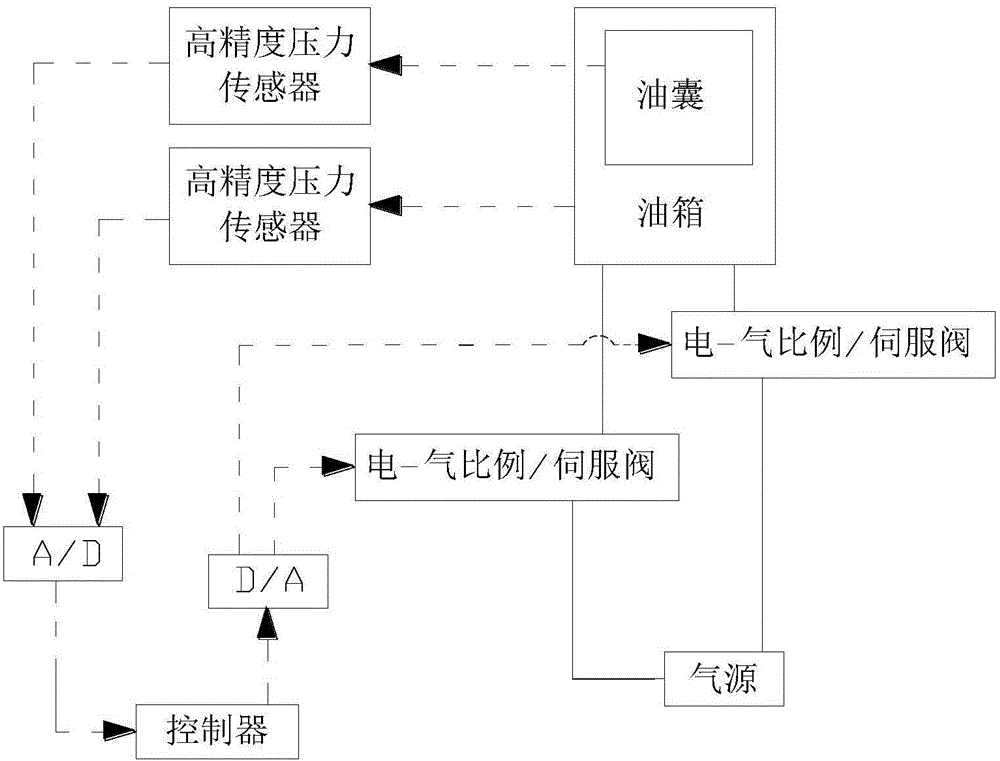

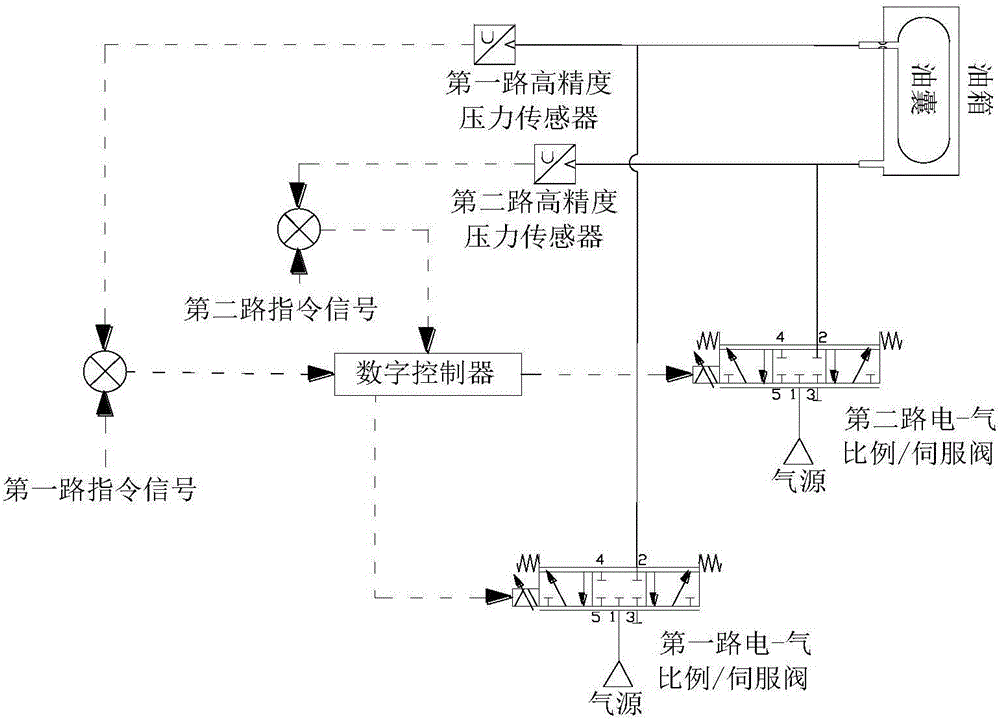

Air tightness detecting device and servo control method thereof

ActiveCN106197902ACheck air tightnessPrecise pressure controlMeasurement of fluid loss/gain rateElectricityDifferential pressure

The invention discloses an air tightness detecting device and a servo control method thereof. The air tightness detecting device comprises a first gas source, a first pressure sensor and a first proportional servo valve. The first gas source and the containing cavity of a first object to be detected are connected by a first proportional servo valve. The first pressure sensor is connected to the containing cavity of the first object to be detected and is used for detecting the pressure in the containing cavity of the first object to be detected so as to judge the air tightness of the containing cavity of the first object to be detected. The first pressure sensor is also connected to the first proportional servo valve and is used for adjusting the state of the first proportional servo valve. Through improving control loop design and a server control process, the problems of the low accuracy of a direct pressure testing method and the inconvenient operation of a differential pressure test method are solved effectively, according to the device and the corresponding servo control method, the opening of an electro-pneumatic proportional servo valve is controlled through a closed-loop system to control the flow of gas in the loop, and the air tightness of the system can be detected.

Owner:HUAZHONG UNIV OF SCI & TECH

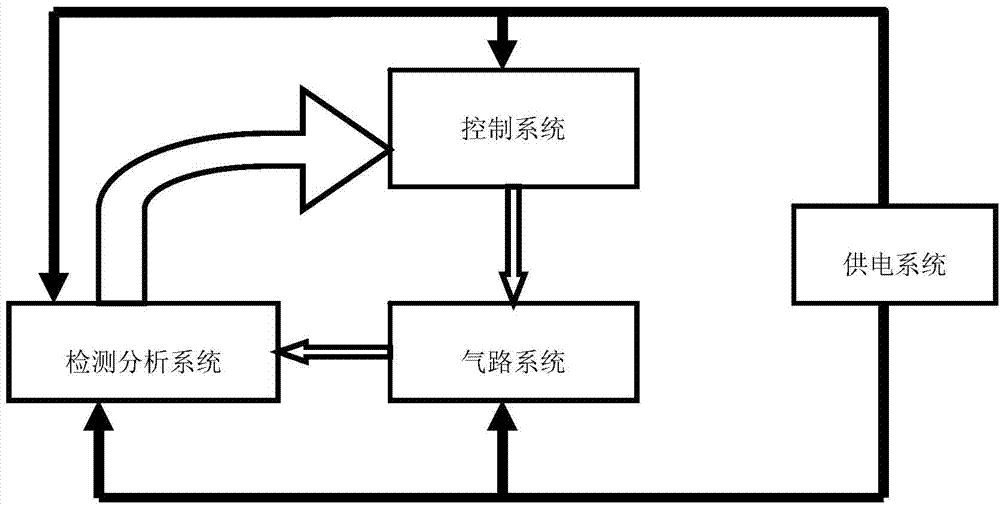

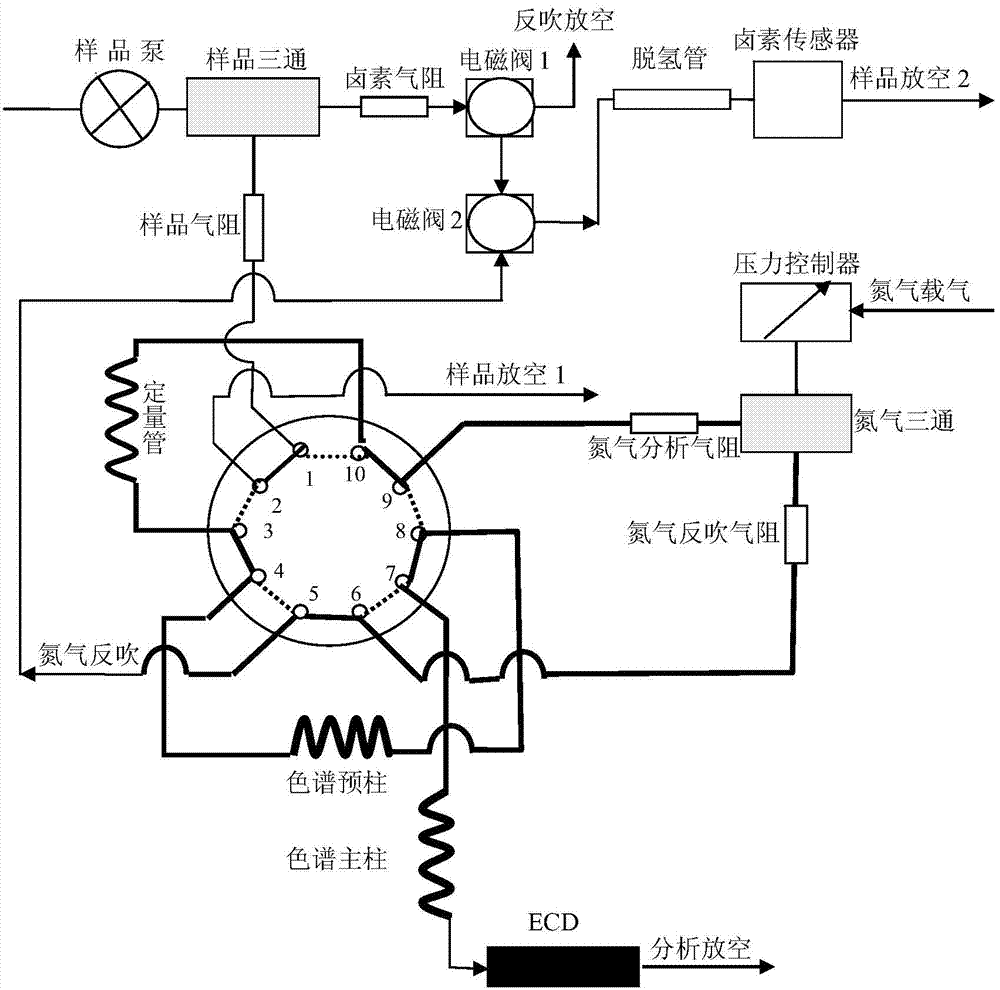

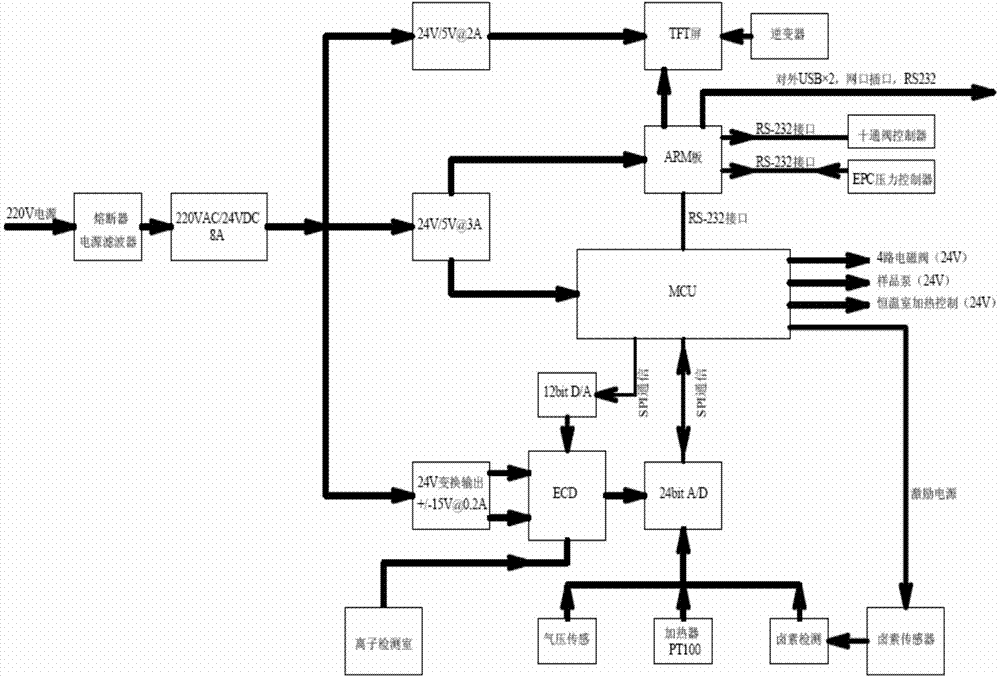

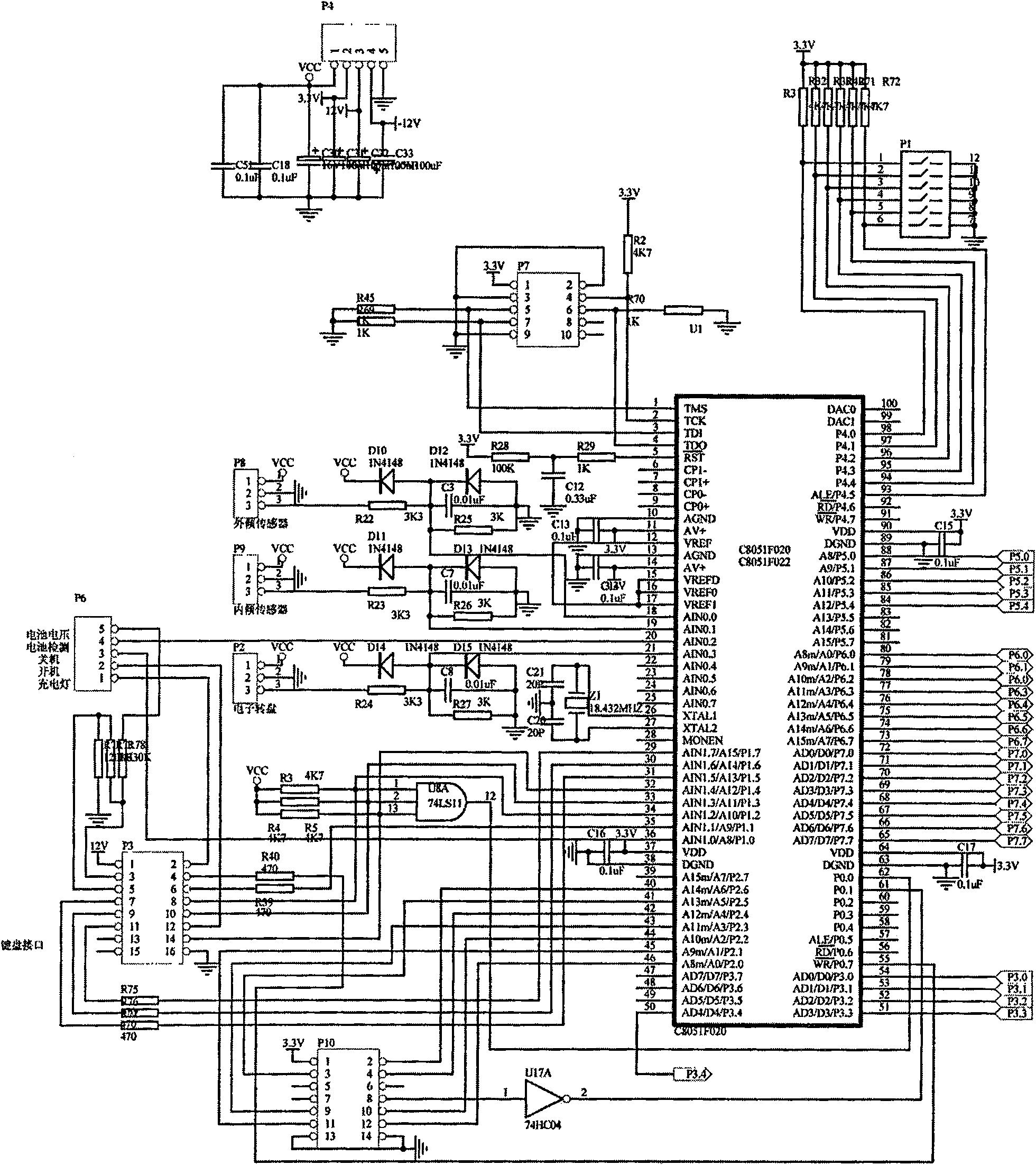

Freon gas detection warning device and detection method thereof

InactiveCN103808820AGood separation effectAccurate measurementComponent separationProduct gasEngineering

The invention belongs to the technical field of analysis and detection, and particularly relates to a Freon gas detection warning device. The invention discloses the Freon gas detection warning device which comprises a detection and analysis system, a gas path system, a control system and a power supply system, wherein the detection and analysis system, the gas path system and the control system are connected with one another, and the power supply system is used for supplying power to the detection and analysis system, the gas path system and the control system. The Freon gas detection warning device disclosed by the invention has the characteristics of good separation effect, accuracy in measurement, high interference resistance, good repeatability and the like, and can be used for qualitative analysis as well as quantitative analysis of F1301, F-11, F-12 and F22; the adopted technical principle is advanced; the Freon gas detection warning device is reasonable in design, convenient to use and maintain, and high in standardization level and universalization level.

Owner:NAVY MEDICINE RES INST OF PLA

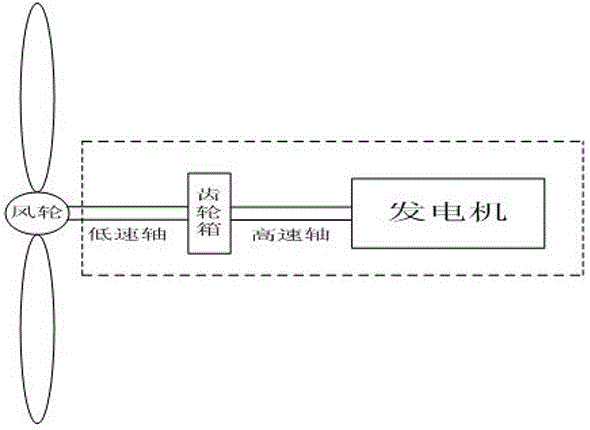

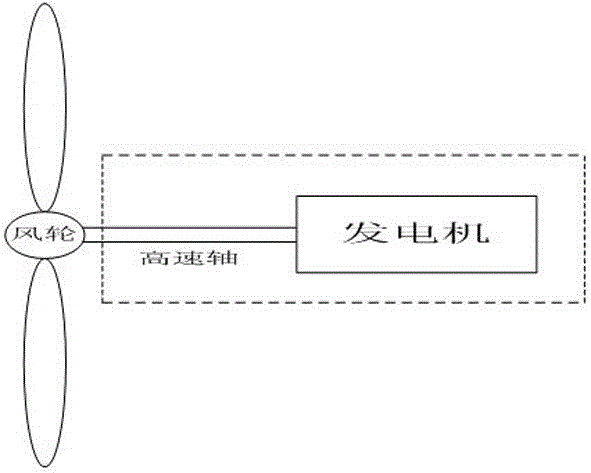

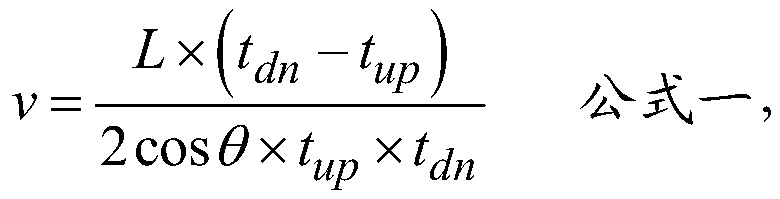

Method for acquiring wind speed value of wind driven generator

ActiveCN105138845ADoes not affect normal operationNot easy to influenceSpecial data processing applicationsObservational errorWind driven

The invention discloses a method for acquiring a wind speed value of a wind driven generator. A mathematical model used for solving the wind speed is built by means of parameters, corresponding to the wind speed, of the wind driven generator, and then the wind speed value is calculated through the model. The method has the advantages that wind speed sampling points are accurate, the acquired wind speed value is real and reliable, high in precision and free of measuring errors, and a wind speed measurement device does not need to be used.

Owner:东方电气风电股份有限公司

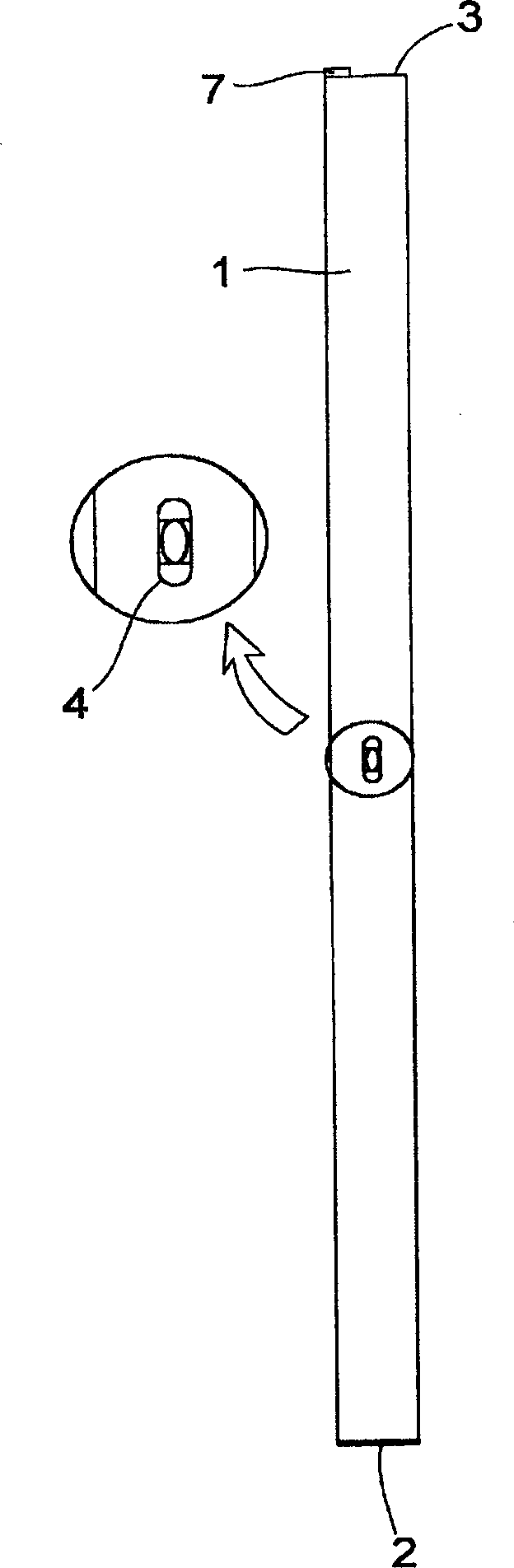

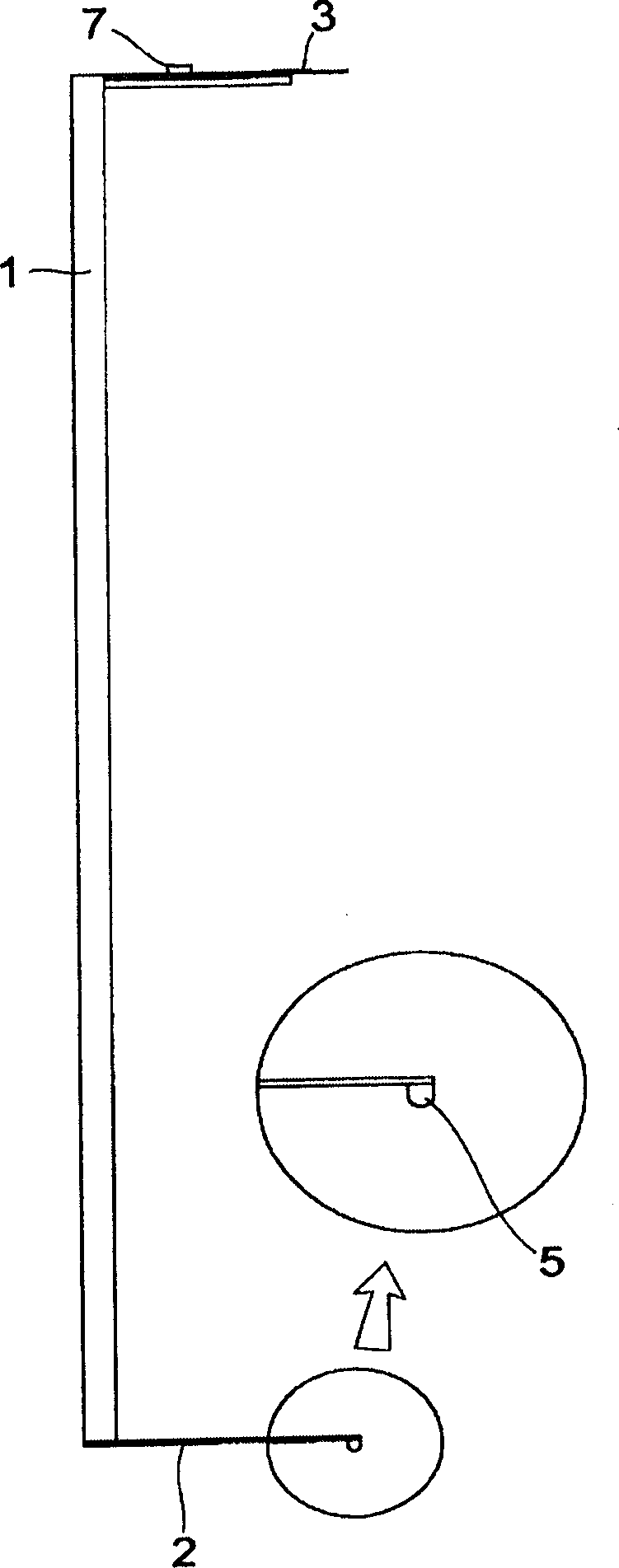

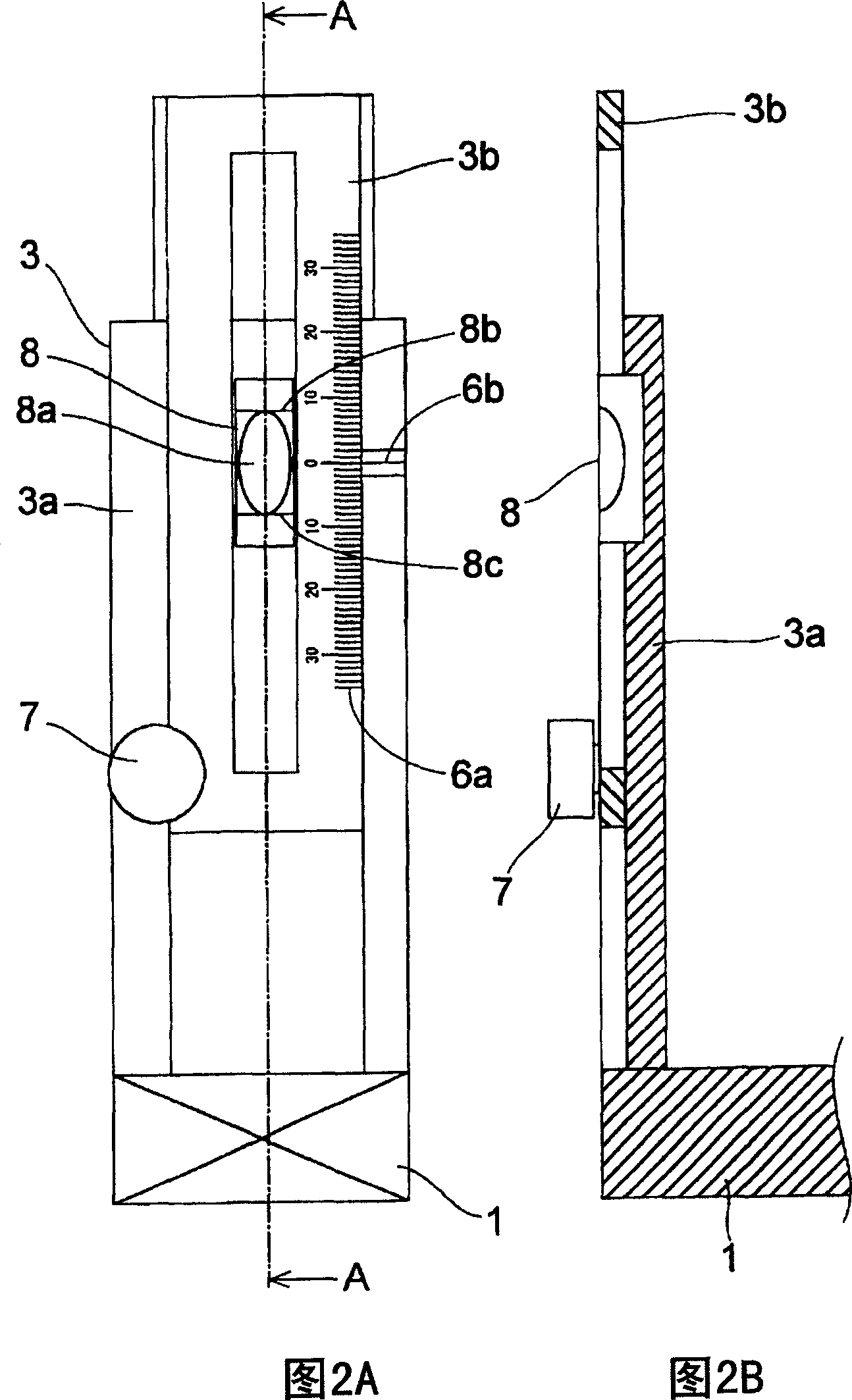

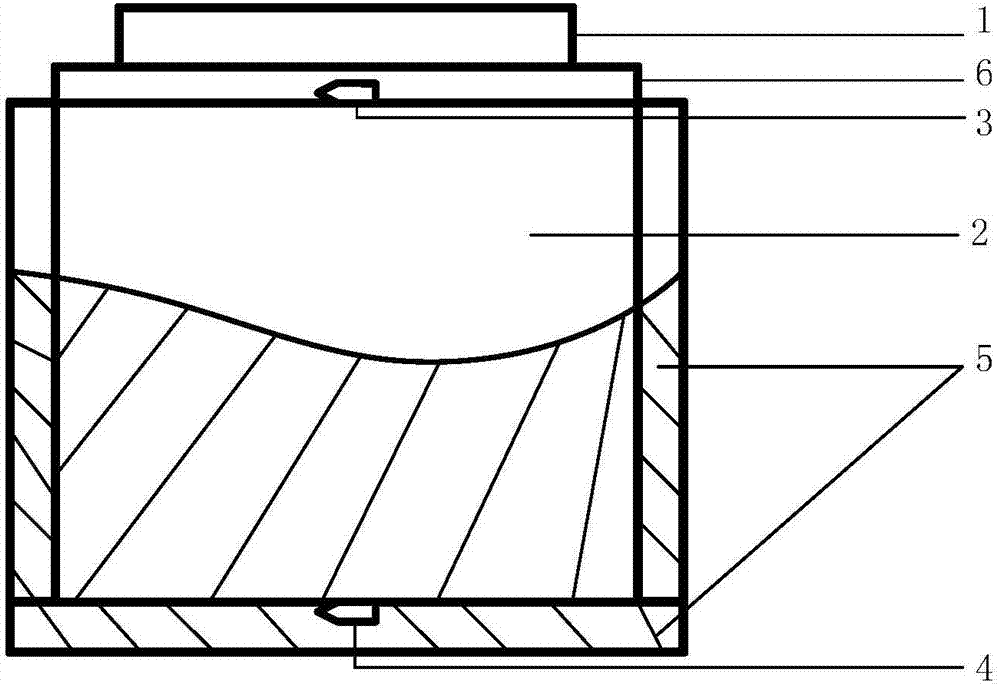

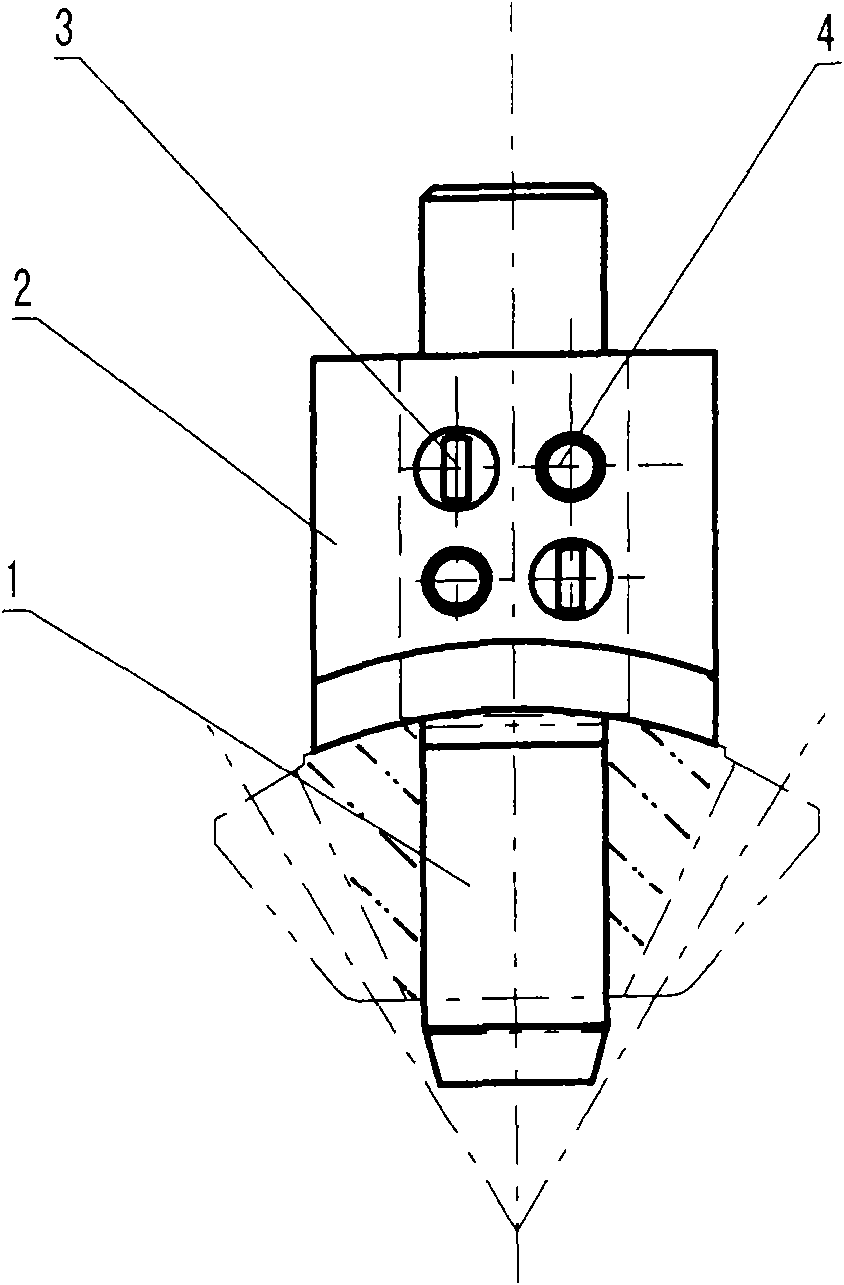

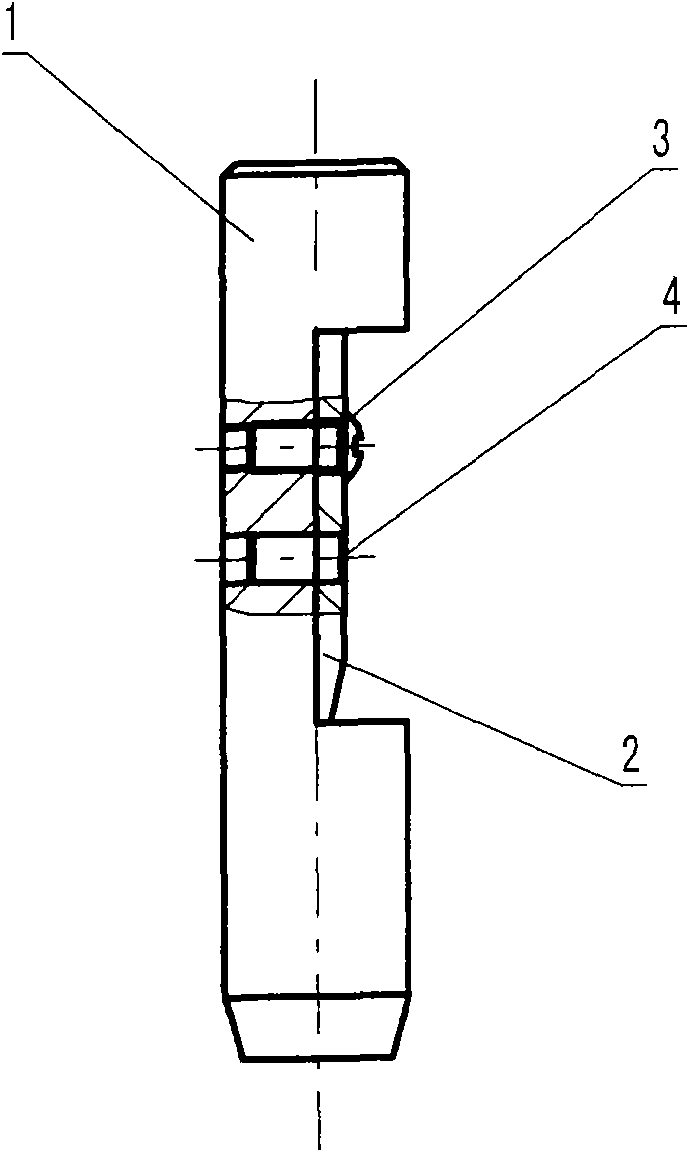

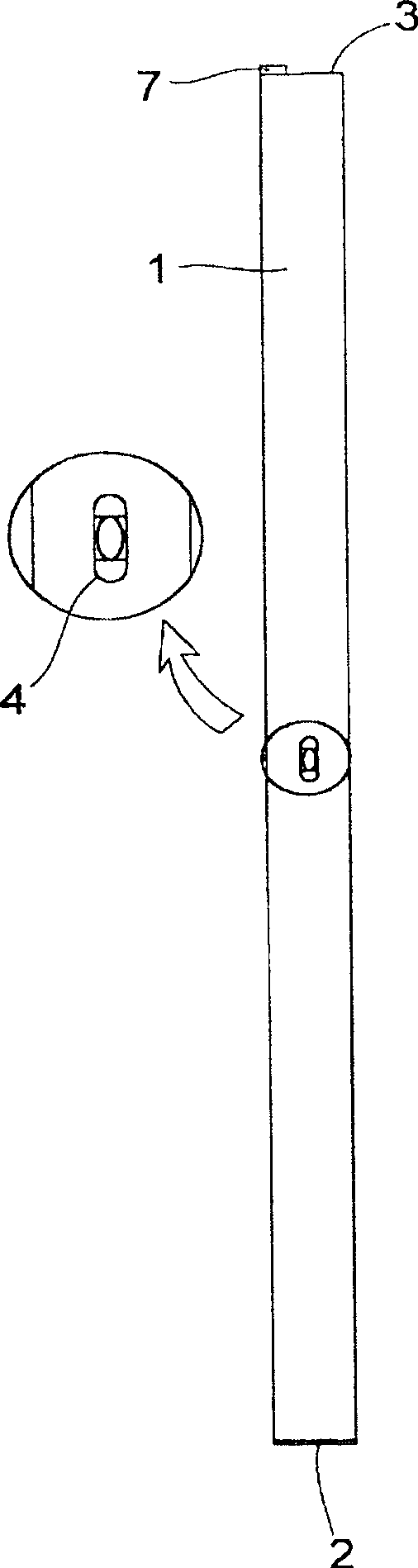

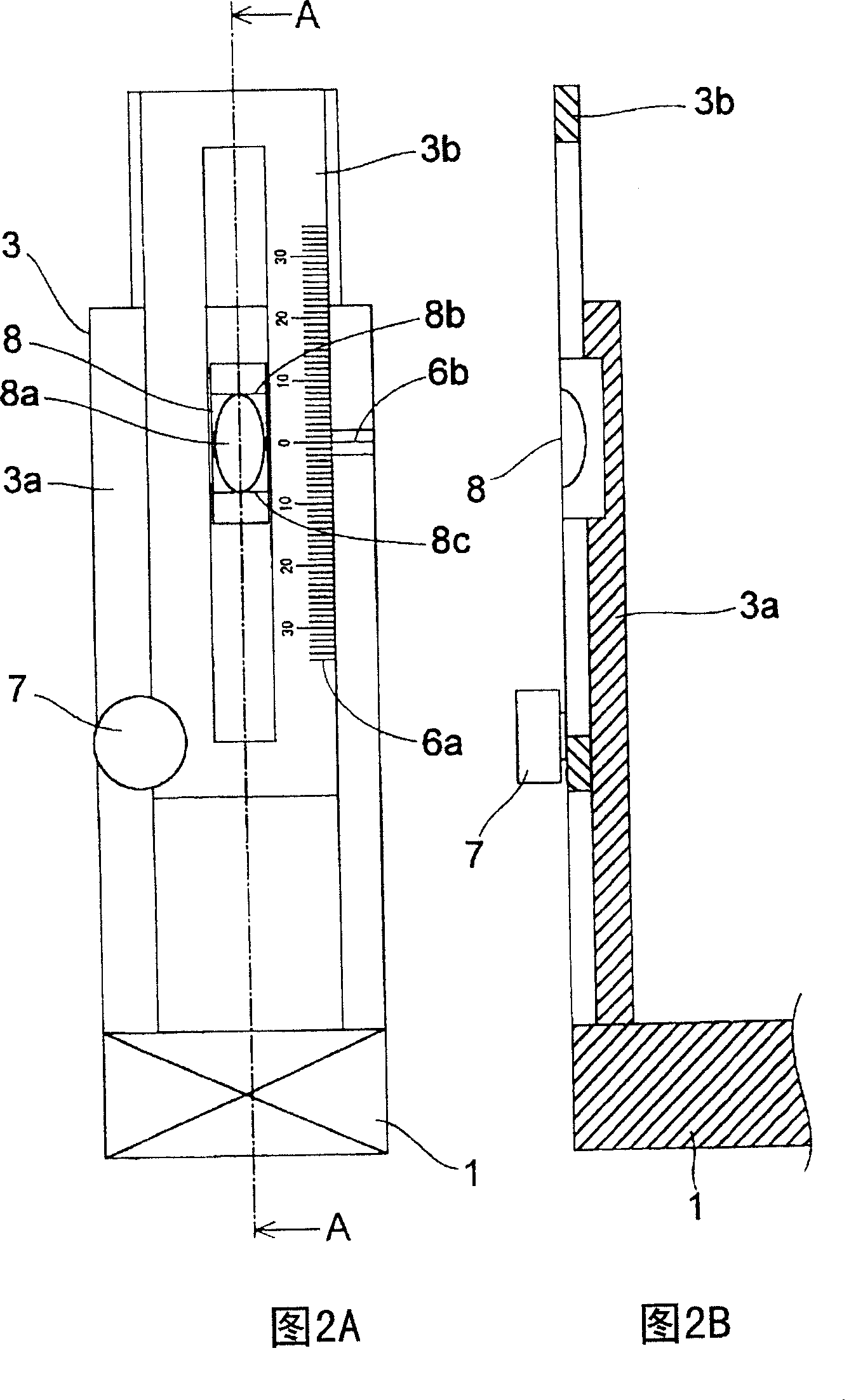

Inclination measurement instrument

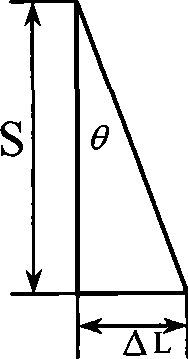

InactiveCN1711459ANo measurement errorConfirm levelIncline measurementObservational errorEngineering

The invention relates to an inclinometer measuring instrument which is not equipped with a pendulum and a circular dial on the main body of the inclinometer, is not easy to produce measurement errors, and can measure the inclination of a measured object in a short time. It has a main body frame (1) configured along the measured surface H and a reference arm (2) and a telescopic arm (3) that are in contact with the above-mentioned measured surface H. The reference arm (2) and the telescopic arm (3) are vertically aligned It is arranged at both ends of the main body frame (1) in the same direction, and the telescopic arm (3) is equipped with a slide rule that moves with the expansion and contraction of the telescopic arm (3) and a bubble gauge for observing the levelness of the telescopic arm. If the front ends of the reference arm (2) and the telescopic arm (3) are docked to the surface H to be measured and the telescopic arm (3) is stretched, and the level of the telescopic arm (3) is adjusted according to the bubble gauge of the telescopic arm, then the Measure the inclination of the measured surface H.

Owner:吉乡悟

A Test Method for Absolute Time Delay of Satellite Transponder

A method for testing the absolute time delay of a satellite transponder. First, an angle-modulated microwave signal source is used to output an angle-modulated microwave signal, and then the angle-modulated microwave signal is divided into two paths. One path is input to the entrance of the satellite transponder through an attenuator, and the other path The signal is used as the input of an A / D converter, and the output signal of the satellite transponder is input to another A / D converter after passing through a high-power attenuator. The two A / D converters use the same reference clock to sample data synchronously, and then demodulate the angle modulation signal on the two-way A / D sampled data to obtain the baseband signal of the two-way A / D sampling signal. The two baseband low-frequency periodic signals are compared to obtain the absolute time delay between the two baseband signals represented by the difference in the serial numbers of the sampling points. The number of sampling points multiplied by the sampling period is the absolute Delay, after deducting the delay calibration value of the attenuator and the connecting cable, it is the absolute delay of the satellite transponder.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

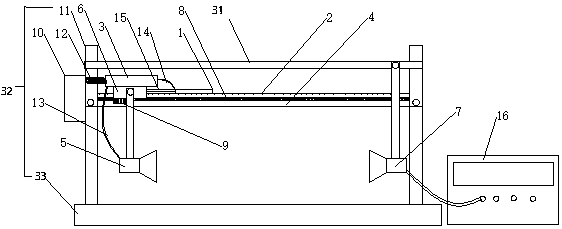

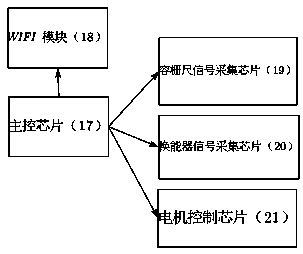

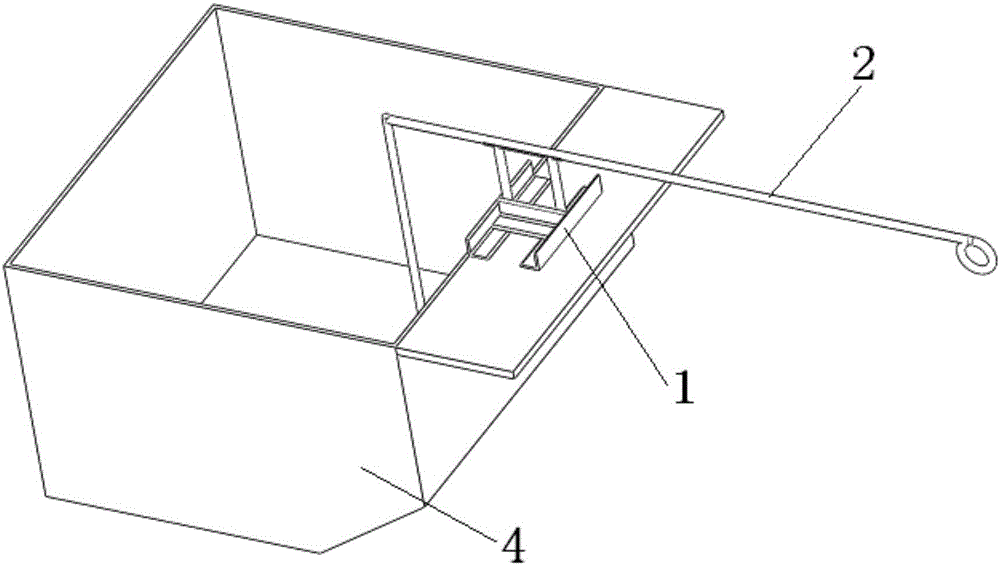

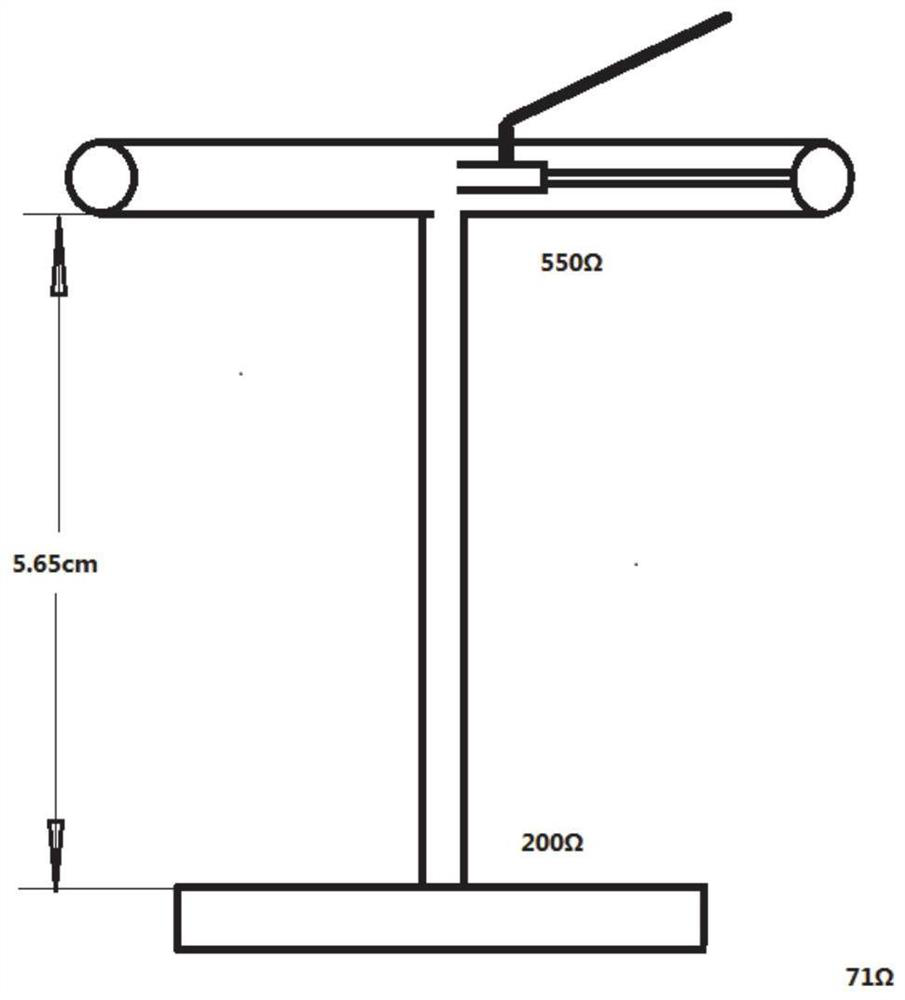

Full-automatic standing wave resonance method sound velocimeter based on WIFI

ActiveCN109741666AEasy to placeSolve the complex connectionVelocity propogationEducational modelsCapacitanceWireless control

The invention discloses a full-automatic standing wave resonance method sound velocimeter based on WIFI. The full-automatic standing wave resonance method sound velocimeter based on WIFI comprises a slidable grid-capacitance type ruler head, a grid-capacitance type ruler body, master control equipment, a carrying rack in the middle of the sound velocimeter, a receiving end transducer, a carrying seat for fixing the receiving end transducer, an emitting end transducer, a straight rack fixed to the carrying rack, a gear at the bottom of the transducer carrying seat, a power supply, an instrumentside rack, a spring electric wire, a receiving end transducer signal line, a grid-capacitance type ruler signal line, a connecting rod of the carrying seat and the grid-capacitance type ruler head and an ultrasonic signal emitter. By means of wireless control, complex connection of the electric wire is avoided, the instrument is placed conveniently, and the sound velocimeter can be used for teaching demonstration. Meanwhile, by adopting a wireless scheme of WIFI, measured data can be shared in LAN, so that the teaching means is enriched.

Owner:NANJING FORESTRY UNIV

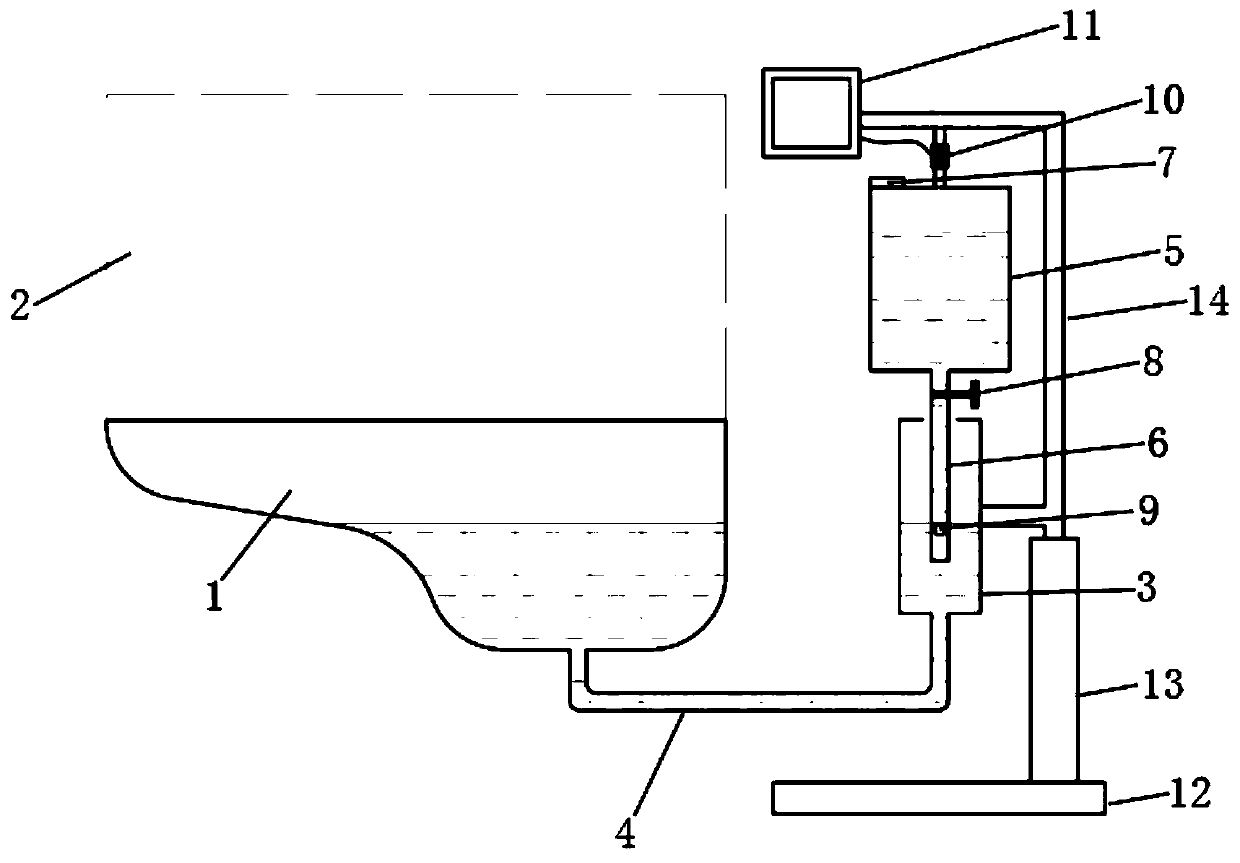

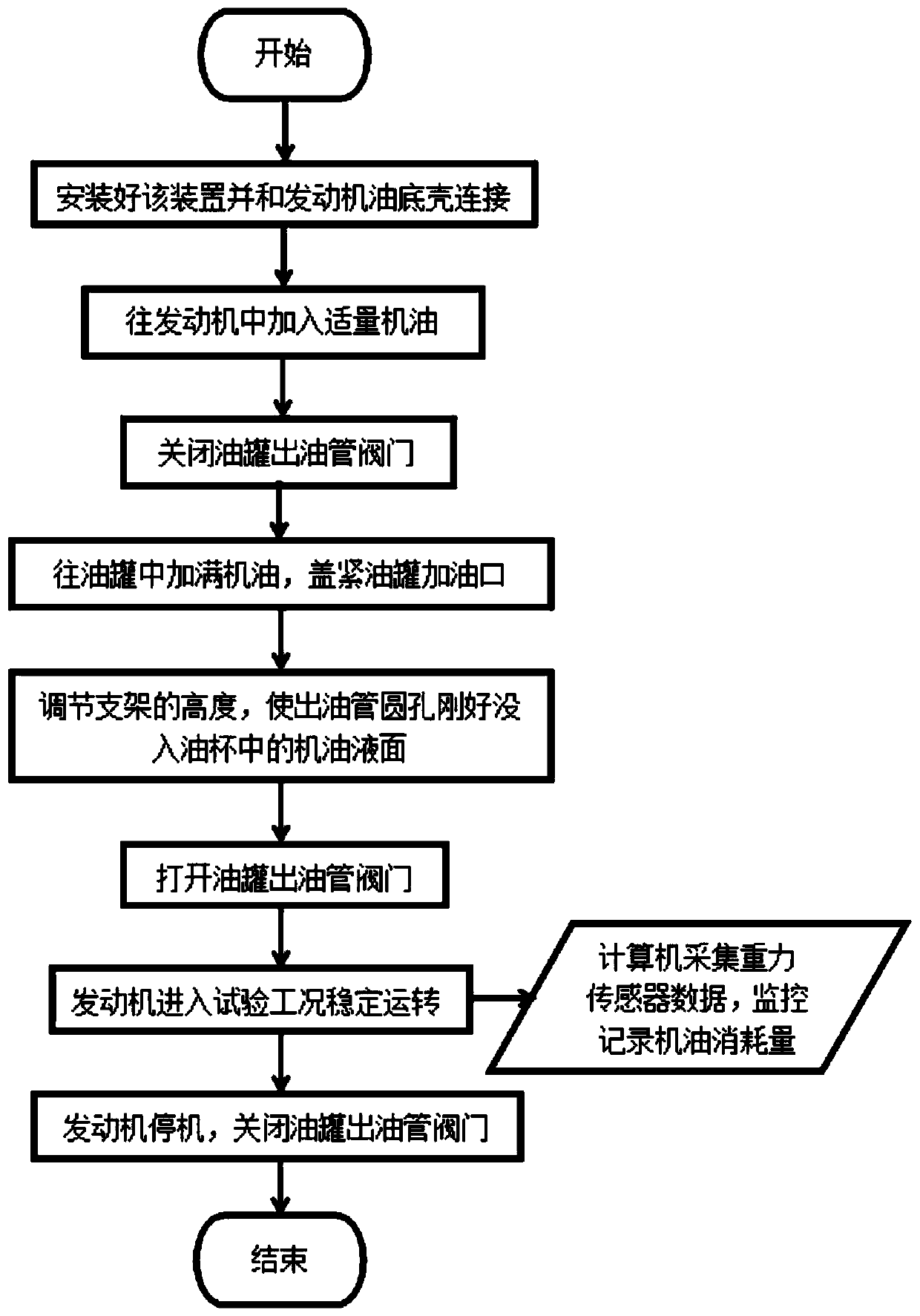

Engine oil consumption real-time testing method and device

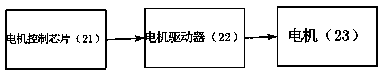

PendingCN111102035ARealize monitoringImplement testLubrication indication devicesFrequency changerControl engineering

The invention discloses an engine oil consumption real-time testing method, and relates to the technical field of engine detection. The technical problems of low degree of accuracy and large error ofexisting technology testing are solved. The engine oil consumption real-time testing method comprises the steps that engine oil is added into an engine, a liquid level in the engine is fed back in real time, and the engine is started for testing; the following process is repeated until the testing is finished, specifically, the engine oil consumed in the testing process is supplemented for the engine in real time according to the initial liquid level in the engine, so that the engine oil in the engine keeps the initial liquid level, and the supplemented engine oil quantity is monitored in realtime; and the testing is finished, and monitoring data for the engine oil quantity is output. The invention further discloses an engine oil consumption real-time testing device. The structure is simple, equipment such as an oil pump and a frequency converter are not needed, complex staking-work is further not needed in use, using is simple, the testing degree of accuracy is high, and the testingerror is small.

Owner:GUANGXI YUCHAI MASCH CO LTD

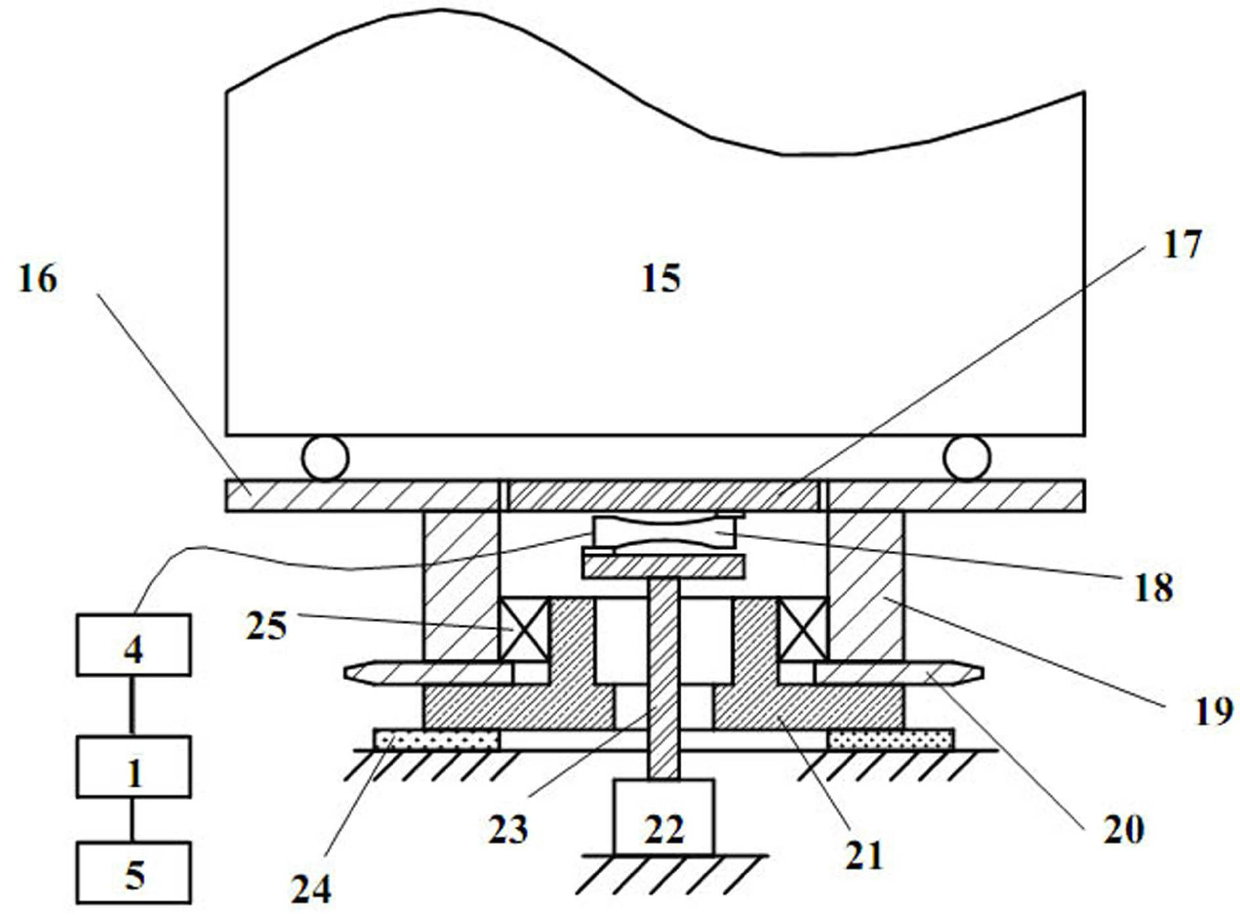

Measurement method and measurement device for waste percentage of combing machine

ActiveCN102392330AIncrease productivityNo measurement errorCombing machinesWeighing apparatus with automatic feed/dischargeMeasurement deviceEngineering

The invention relates to a measurement method and a measurement device for the waste percentage of a combing machine. The measurement method comprises the following steps of: measuring a weight G of laps fed into the combing machine and a weight g of combed laps output by the combining machine in unit time; and calculating the waste percentage eta (percent) of the combing machine according to the following formula. The invention also provides the measurement device for the waste percentage of the combing machine, which comprises a control device, a signal processing device, a lap weighing mechanism and a sliver can weighing mechanism. The lap weighing mechanism comprises a lap tray, a lap weighing sensor and a lap tray lifting mechanism. The sliver can weighing mechanism comprises a sliver can rotating mechanism, a lifting disk, a sliver can weighing sensor and a disk lifting mechanism. In the invention, a method of weighing the laps and a silver can on line is adopted; the waste percentage is calculated to be obtained by the control device; and the measured combing waste percentage is accurate; the harmful effect on the operation and the spinning quality of the combing machine cannot be generated in the whole measuring process; and in the measuring process, return slivers and return laps cannot be generated, so the measurement method and the measurement device are beneficial for improving the production efficiency.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Power device loss test method

ActiveCN107167666AAccurate lossMeeting and adapting to testing needsDielectric property measurementsObservational errorTest power

The invention discloses a power device loss test method. The method includes the following steps: (1) a loss correction test which is intended for drawing a loss curve describing how the loss of a to-be-tested power device changes over temperature differences; (2) an actual circuit test which is intended for enabling the to-be-tested power device to work normally and obtaining the power value of the to-be-tested power device on the basis of the curve which is obtained in the loss correction test in correspondence to the temperature difference from actual measurement. The method can obtain loss values under actual working conditions, can meet test requirements under any working condition, overcomes measurement errors caused by inaccuracy and delay of electric measuring devices (such as an oscilloscope), can produce a test result which is free from instability of environment temperature and starting temperature, and can obtain accurate power device loss data.

Owner:HEFEI UNIV OF TECH

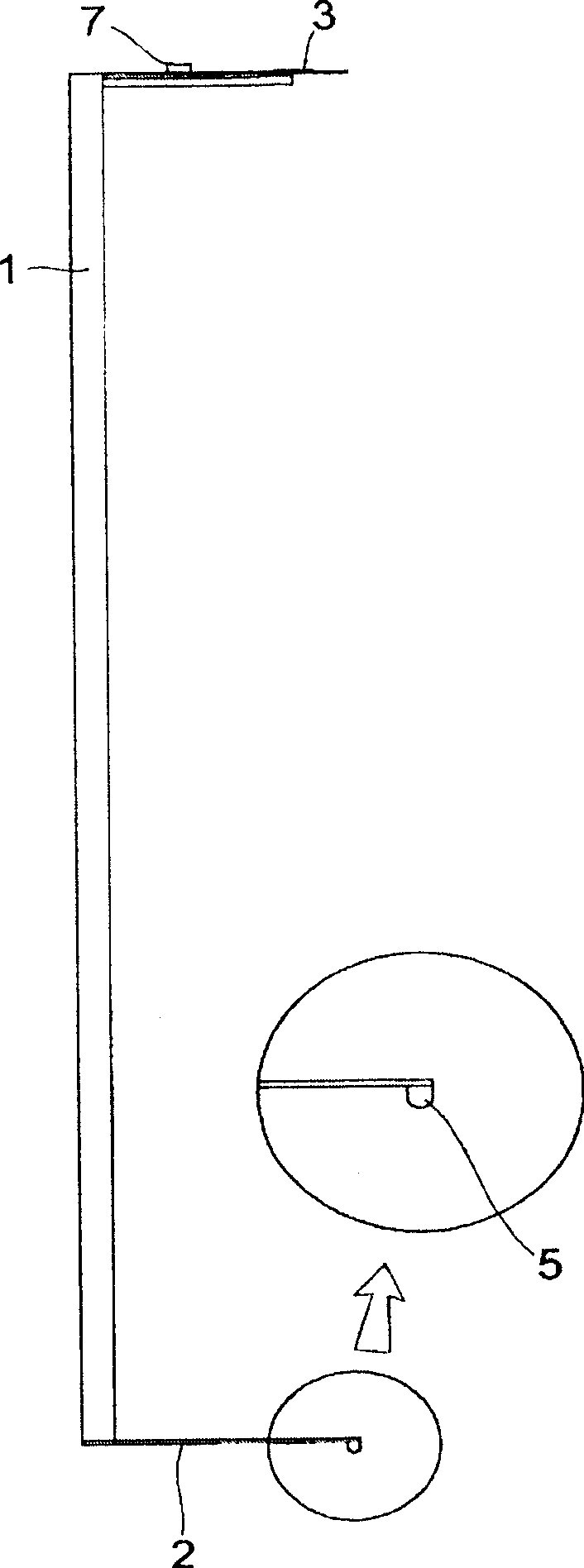

Measuring method and tool for electrolyte level or aluminum level in aluminum electrolysis cell

PendingCN106123995ASafe and stable process controlGuaranteed uniform measurement heightMachines/enginesLevel indicatorsOptoelectronicsElectrolytes levels

The invention discloses a measuring method and tool for the electrolyte level or aluminum level in an aluminum electrolysis cell. When the electrolyte level or aluminum level in the aluminum electrolysis cell is measured, a measuring nager is manufactured into an L-type measuring nager formed by a vertical iron rod and a horizontal iron rod, the horizontal iron rod of the L-type measuring nager is placed on a horizontal supporting base, the vertical iron rod of the L-type measuring nager is vertically inserted into electrolyte or molten aluminum in the aluminum electrolysis cell, at the moment, a mark of the electrolyte or molten aluminum will be formed on the vertical iron rod of the L-type measuring nager, then the L-type measuring nager is taken down from the horizontal supporting base and placed on a measuring trolley, the vertical iron rod of the L-type measuring nager is attached to a vertical supporting rod, which is perpendicular to a horizontal support and provided with a graduated scale, of the measuring trolley, in this way, the value corresponding to the mark on the vertical iron rod can be directly read from the graduated scale of the vertical supporting rod, and the value is a measurement value. The measuring method and tool have the advantages of being high in measurement precision and efficiency, small in measuring workload, simple in structure, convenient to operate and use and the like.

Owner:GUIYANG AL-MG DESIGN & RES INST

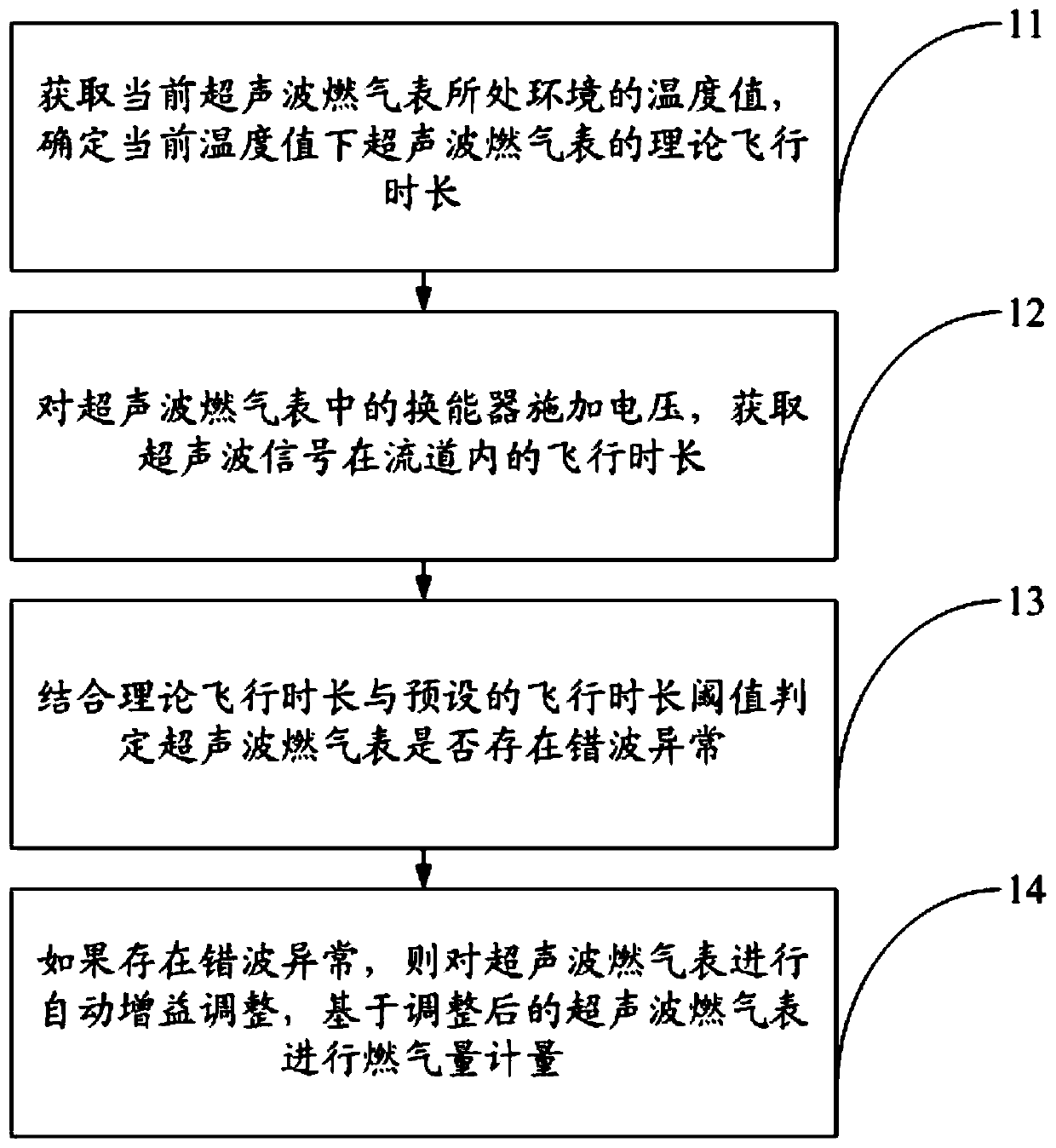

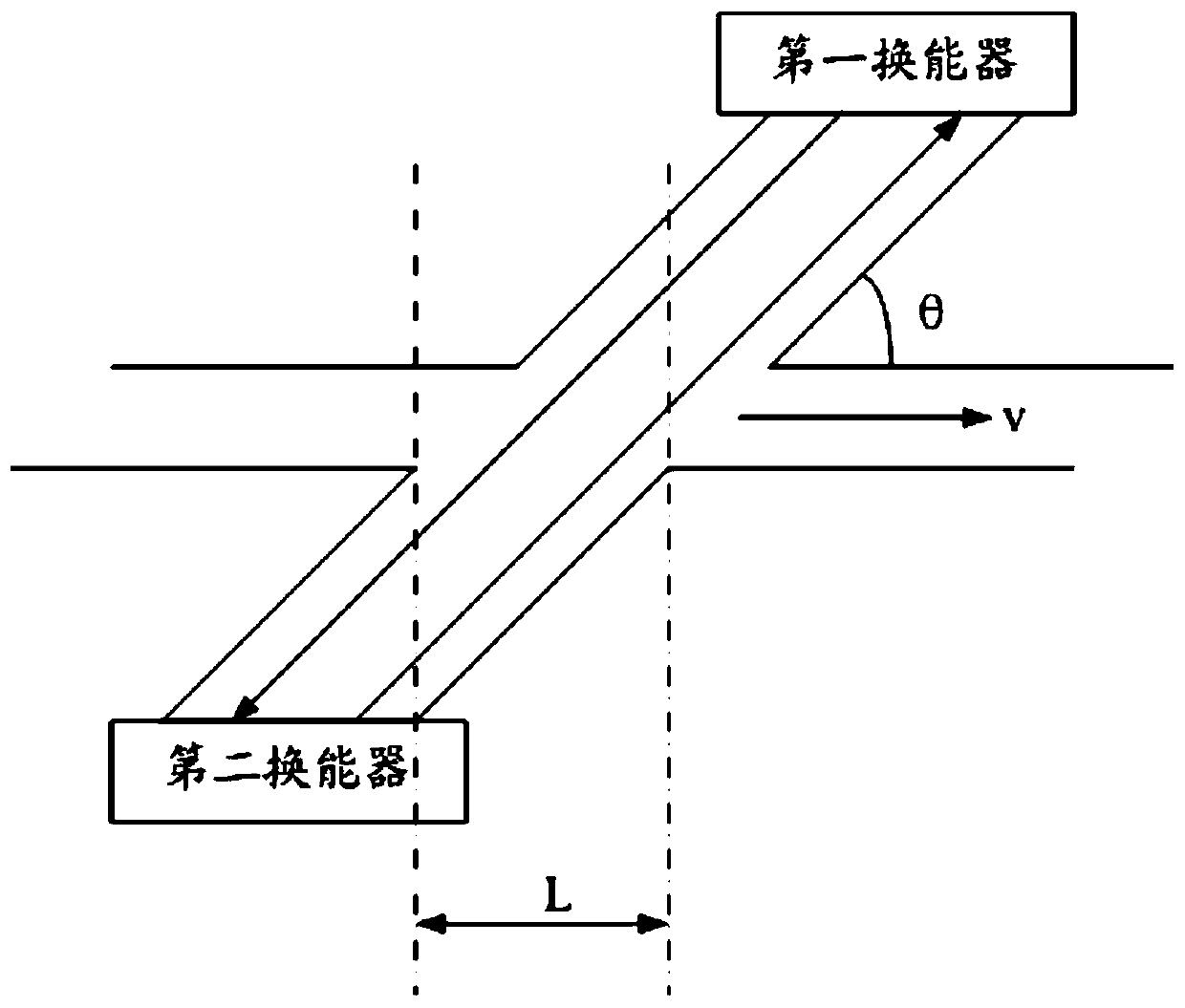

Ultrasonic gas meter measurement data adjustment method

ActiveCN109696217AHigh precisionExpand the scope ofTesting/calibration apparatusVolume variation compensation/correction apparatusTraffic volumeData Adjustments

The invention provides an ultrasonic gas meter measurement data adjustment method, which belongs to the measurement field. The method comprises steps: the temperature value of the environment in whichthe ultrasonic gas meter is located currently is acquired, and the theoretical flight time under the current temperature value is determined; the flight time of ultrasonic signals in a runner is acquired; in combination of the theoretical flight time and a preset flight time threshold, whether an error wave anomaly exists in the ultrasonic gas meter is judged; and if an error wave anomaly exists,automatic gain adjustment is carried out on the ultrasonic gas meter, and based on the adjusted ultrasonic gas meter, gas quantity measurement is carried out. During the process of using the ultrasonic gas meter to measure the gas consumption, a technical characteristic of acquiring a sound standard transmission speed under the temperature value based on the temperature value is introduced, whether an error wave phenomenon exists currently is judged according to the determined sound standard transmission speed, and the defect of possible measurement errors caused by ultrasonic flow measurement can be effectively remedied.

Owner:GOLDCARD HIGH TECH

Method and device for calibrating return compensation type double-optical-axis angular displacement laser interferometer

ActiveCN103528502AAbbe's error is smallLittle differenceUsing optical meansOptical axisRefractive index

A method and a device for calibrating a return compensation type double-optical-axis angular displacement laser interferometer belong to the technical field of laser measurement. Two measurement light beams of the calibrated laser interferometer penetrate through a middle through hole of a double-axis hollow laser interferoscope group; the two measurement light beams of the calibrated laser interferometer are arranged in the middle positions of two parallel standard measurement light beams in parallel; the perpendicular distance between the standard measurement light beams and the measurement light beams of the calibrated laser interferometer is very small, and the air refractive index of the standard measurement light beams is extremely close to that of the measurement light beams of the calibrated laser interferometer; an average derived displacement is measured by a micro-motion device according to two light beam position detectors to carry out return compensation on the derived displacement of a target reflector in real time, so that the incidence positions of the measurement light beams on the reflecting surface of the target reflector do not vary.

Owner:HARBIN INST OF TECH

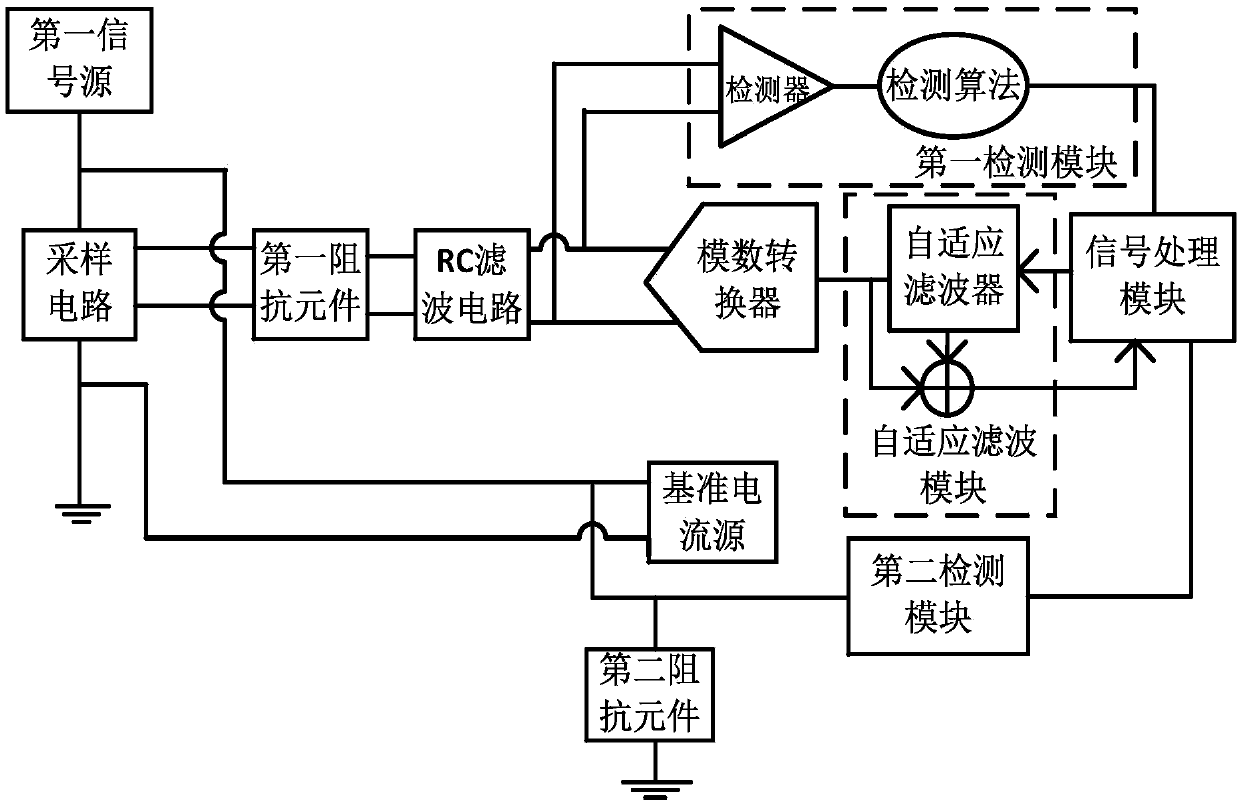

Detection circuit and electric energy metering chip based on circuit and equipment

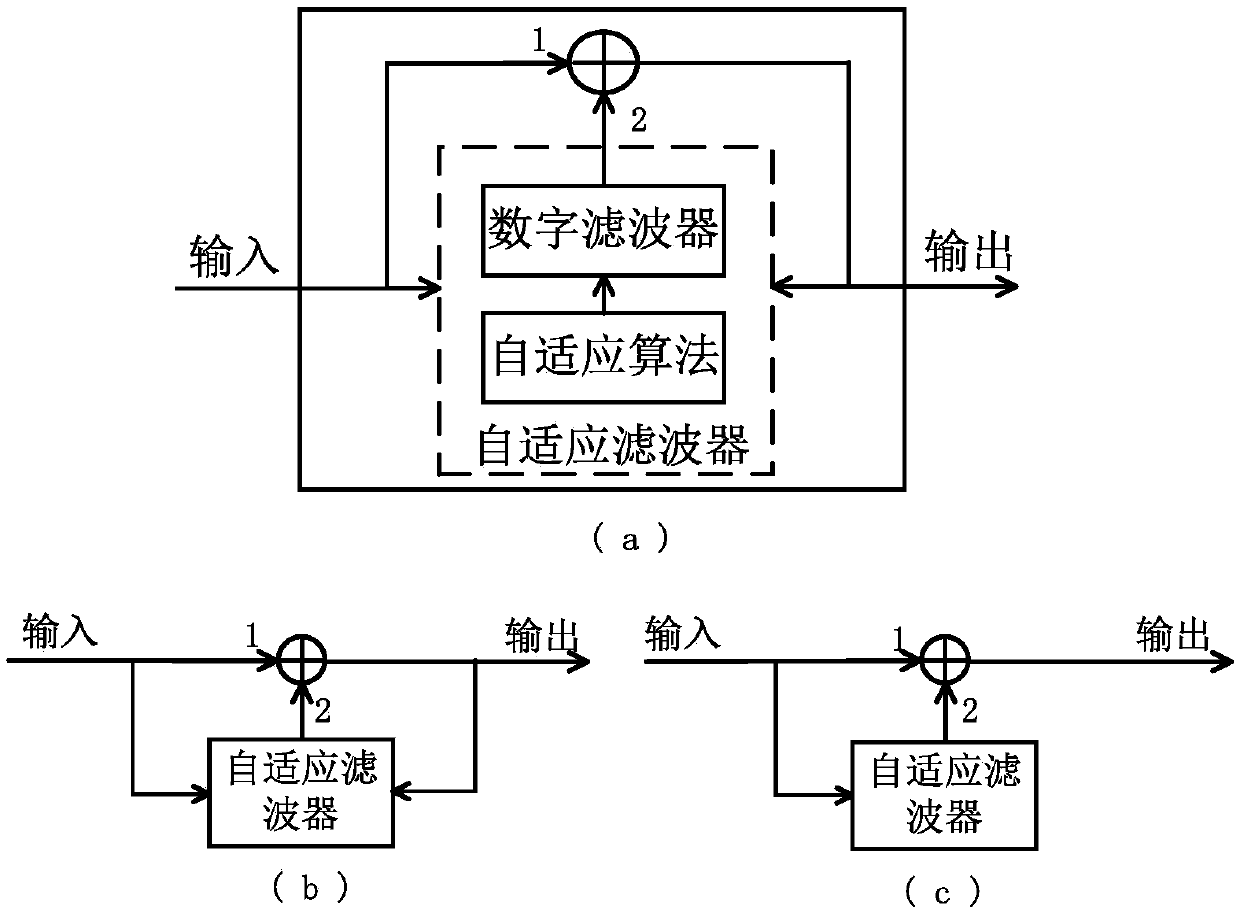

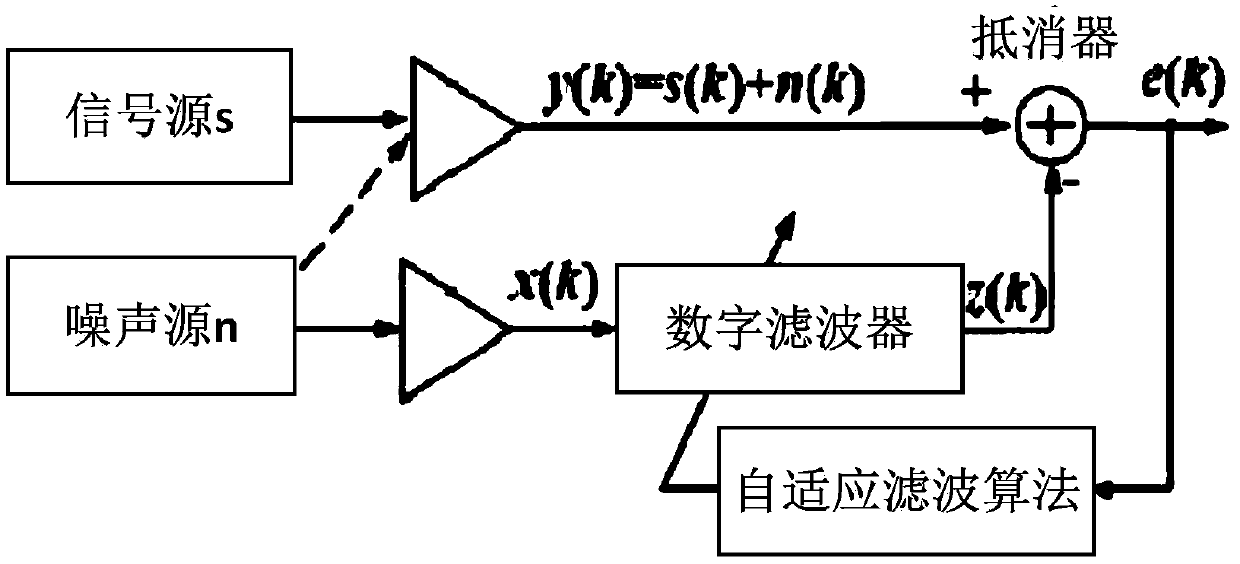

PendingCN111208328AReduce measurement errorSuppression of common mode interferenceTime integral measurementAdaptive filterReference current

The invention relates to the technical field of electric energy metering, and discloses a detection circuit and an electric energy metering chip and device based on the detection circuit and equipment. The circuit comprises a reference current source, a sampling circuit, an adaptive filtering module, a signal processing module, a disconnection working condition detection circuit and protection measures adopted for the working condition. The adaptive filtering module is adopted, the metering error caused by the change of the frequency of the reference current source or the interference in the sampling signal is greatly reduced and the detection precision of the detection circuit is improved; meanwhile, the detection circuit is designed for various wire disconnection working conditions in the detection circuit, disconnect protection measures are correspondingly designed, and the reliability and the safety of operation of the metering system are improved.

Owner:HI TREND TECH SHANGHAI

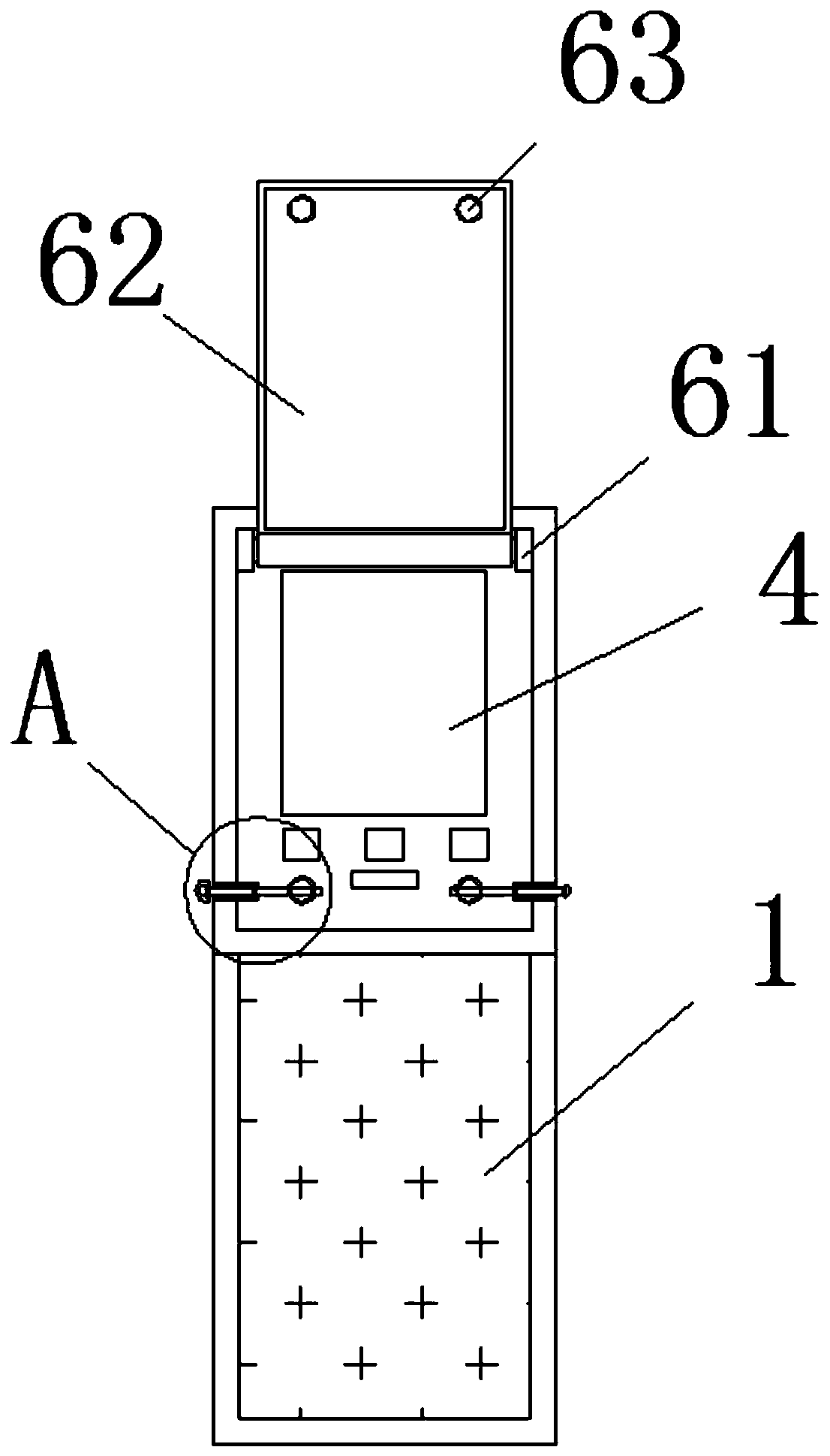

Handheld infrared temperature measuring instrument

PendingCN111307301AAccurate measurementNo measurement errorRadiation pyrometryDiagnostic recording/measuringMeasuring instrumentHand held

The invention discloses a handheld infrared temperature measuring instrument comprising an infrared temperature measuring instrument main body. A grip bin is arranged on the infrared temperature measuring instrument main body, an inductive head is arranged at the left end of the infrared temperature measuring instrument main body, a display screen is arranged at the right end of the infrared temperature measuring instrument main body, a control device is arranged in the grip bin, and a protection device is arranged on the display screen. The hand-held infrared temperature measuring instrumentis provided with a control device. The control device comprises a rotating shaft, a first bevel gear, a second bevel gear, a sleeve rod, a threaded rod and a soft cushion. According to the infrared temperature measuring instrument, the infrared temperature measuring instrument main body can make measurement more accurately without causing measurement errors; the infrared temperature measuring instrument is further provided with a protection device comprising a pin shaft, a protection plate, a clamping rod, a clamping groove, an open groove, a pull ring, an inner bin, a sliding block, a slidinggroove and a spring; and the display screen can be protected through the protection plate, so that the display screen is prevented from being damaged.

Owner:苏州九夺智能科技有限公司

Spherical end face shape and position detector

ActiveCN101629798ASimple structureEasy to measureMechanical counters/curvatures measurementsEngineeringFace shape

The invention discloses a spherical end face shape and position degree detector, which comprises a mandrel, a template, screws and pins, wherein the template is a sheet component and is provided with a knife-edge arc detection surface; the mandrel is provided with a radial opening slot for installing the template, and the depth of the slot is equal to the radius of the mandrel; the flat surface of the template and the bottom surface of the opening slot of the mandrel are attached and are fixedly connected by the screws and the pins, and a vertical center line of the arc of the template is coaxial with an axial line of the mandrel; the radius of curvature of the arc is equal to the radius of the spherical end face to be detected; and the mandrel is in clearance fit with a shaft hole to be detected. The spherical end face shape and position degree detector uses the mandrel as a standard to detect the shape and the position of the spherical end face, has convenient measurement and high detection efficiency, and is particularly suitable to be used as a special on-line detector in large-scale production fields.

Owner:JIANGSU AIRSHIP GEAR

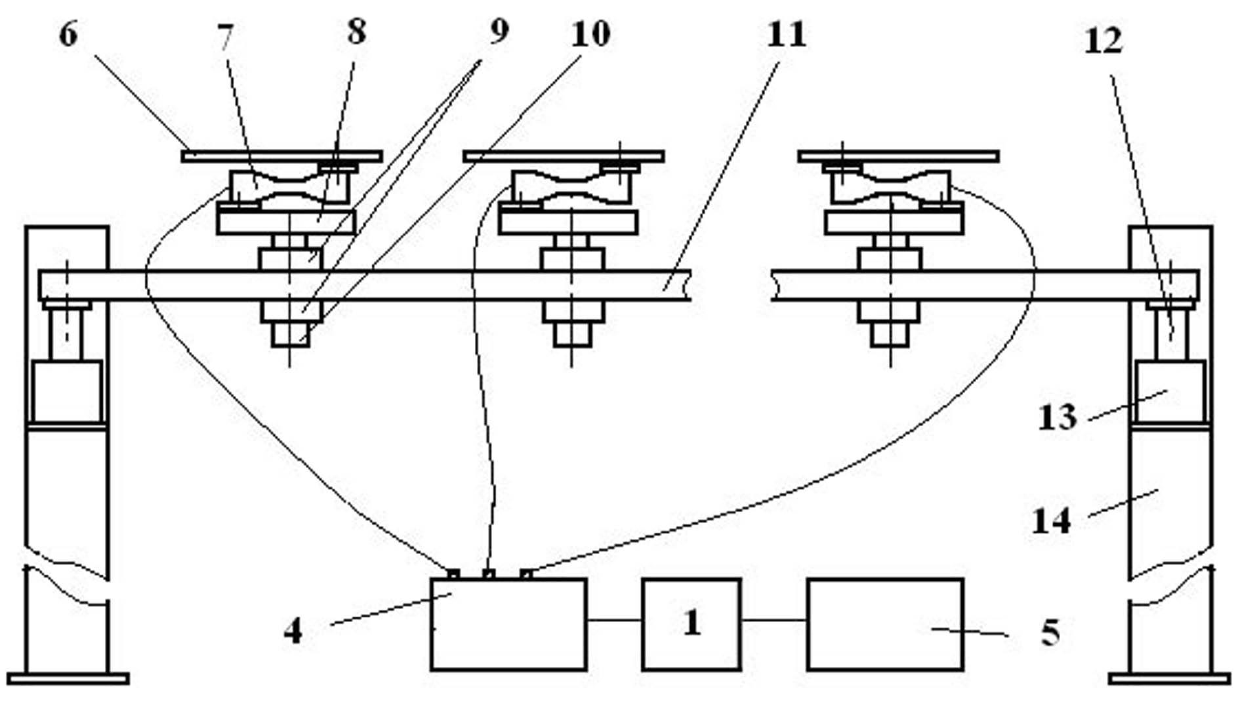

Double front axle cart locator and measuring control method thereof

InactiveCN100575171CReflect the principles of positioningNo measurement errorVehicle testingSteering linkagesVehicle detectionEngineering

Owner:烟台开发区海德科技有限公司

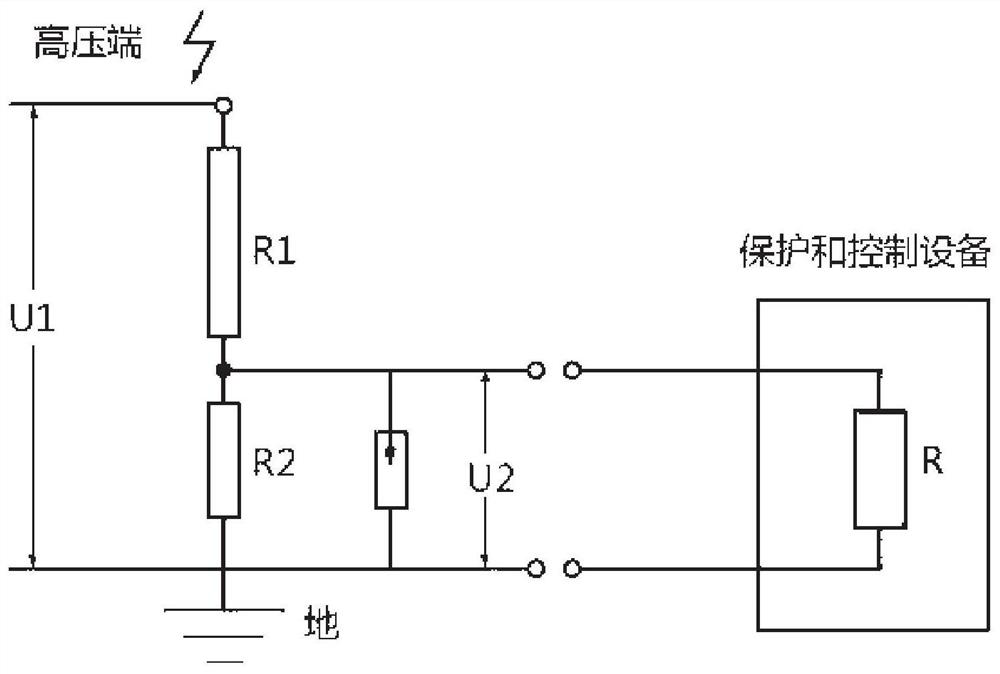

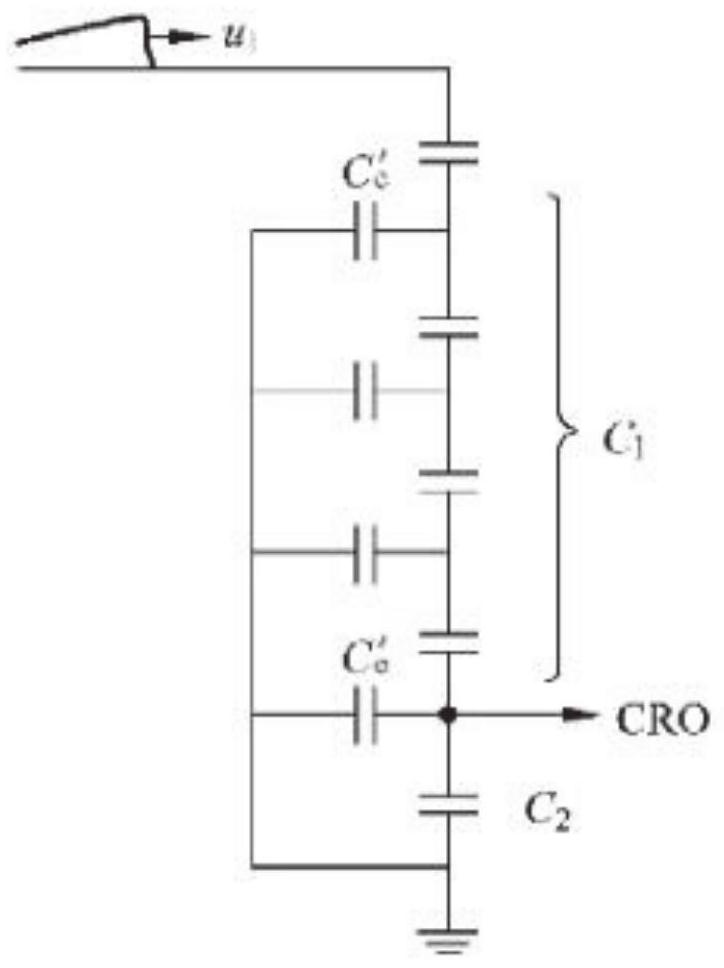

Precise AC/DC broadband voltage dividing device and method

PendingCN112051434AReduce mistakesReduce phase shiftVoltage dividersVoltage measurements onlyCapacitanceInternal resistance

The invention provides a precise AC / DC broadband voltage dividing device and method. The device comprises a resistance voltage dividing module and a buffer module. The resistance voltage division module comprises a high-end resistor and a low-end resistor; the buffer power supply module comprises a buffer; the high-end resistor is configured to receive an input voltage and perform voltage divisionthrough the resistor, and a signal after voltage division is output to the front end of the buffer from the low-end resistor; the high-end resistor and the low-end resistor are connected in parallelwith a compensation capacitor to correct the frequency response curve of the voltage divider; and the buffer converts the high-internal-resistance signal into a low-resistance output signal to carry out broadband precision measurement.

Owner:国网山东省电力公司营销服务中心(计量中心) +3

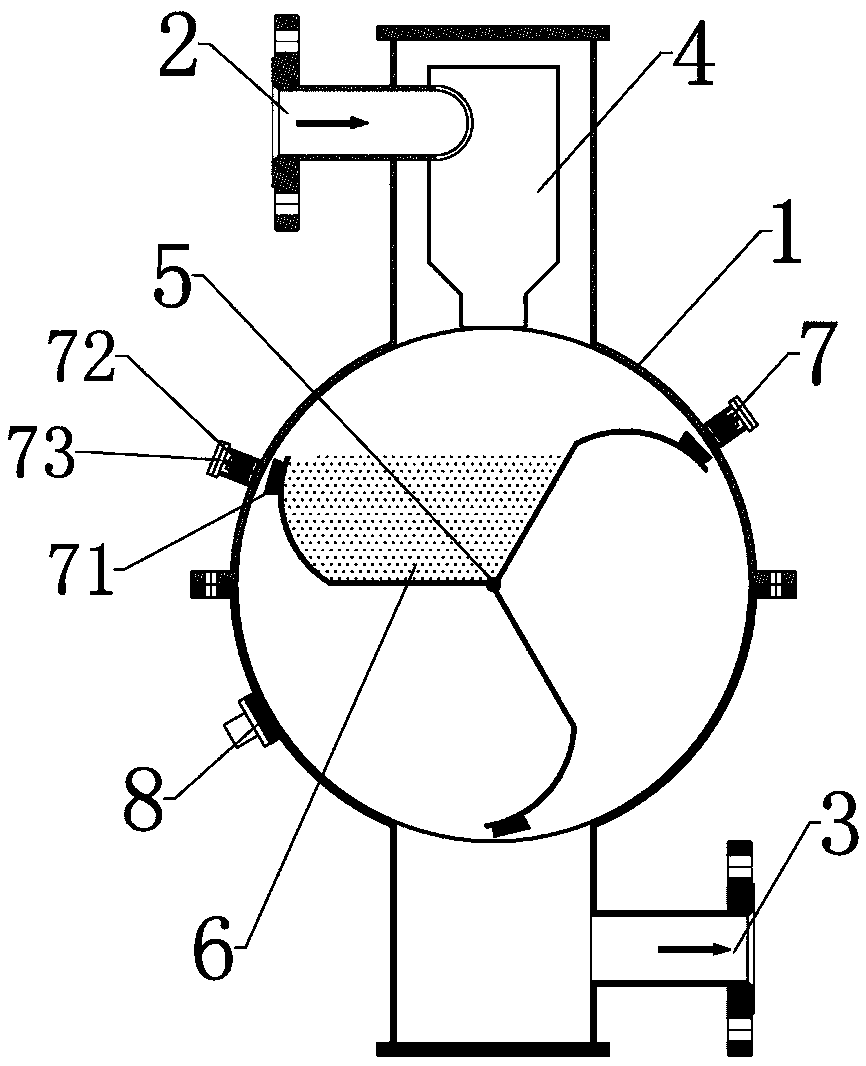

Magnetic quantitative tipping bucket metering device

PendingCN107741258ASolving Measurement ErrorsSolve complexityStationary measuring chambersRotational axisControl theory

The invention provides a magnetic quantitative tipping bucket metering device, which comprises a container shell, a medium inlet in the upper part of the container shell and a medium outlet in the lower part of the container shell, wherein the medium inlet is communicated with a gas-liquid separation device in the container shell, at least three metering buckets and a magnetic quantitative deviceare arranged in the middle of the container shell, and the three metering buckets can continuously rotate around a central rotation axis and are arranged at equal intervals; the magnetic quantitativedevice comprises a magnet A, a magnet B and a position adjusting mechanism, the magnet A is arranged at an edge, close to an inner wall of the container shell, of the metering bucket, the magnet B isarranged on a corresponding outer wall of the container shell, the magnet A and the magnet B can generate interaction force, and the position adjusting mechanism can adjust the magnitude of the actionforce; a counting sensor is arranged on the outer wall of the container shell. The magnetic quantitative tipping bucket metering device disclosed by the invention has the advantages of simple structure, accurate precision, safety, reliability and no mechanical shock.

Owner:杭州飞科电气有限公司

Inclination measurement instrument

InactiveCN100470196CNo measurement errorConfirm levelIncline measurementObservational errorEngineering

Owner:吉乡悟

Permanent magnetic motor gullet torque measuring method

ActiveCN107144381ARealize dense sampling measurement of multiple measurement pointsNo positioning perturbationWork measurementTorque measurementClassical mechanicsElectric machinery

The invention belongs to the motor torque measuring technology and more particularly, to a permanent magnetic motor gullet torque measuring method, characterized by: a tested motor is in tangent contact with the guide rail plane through a circular housing and under the assistance of a baffle plate, positions at the position of the guide rail; when the guide rail moves, the tested motor rolls and through a precise moving platform, the moving length of the tested motor is determined; the motor shaft at the geometrical center of the circular housing ensures that the initial angle is possible at any measuring point through a horizontal balanced rod. The balanced rod is ensured to be at a horizontal state at any measuring point through the horizontal ruler, the counterweight, the screw rod support rod and the electronic scale. According to the lever balance principle and through the torque equilibrium equation, it is possible to accurately work out the gullet torque at any measuring point. Through the gradual movement and the measurement along the guide rail, the discrete waveform for the motor gullet torque could be obtained.

Owner:SICHUAN UNIV

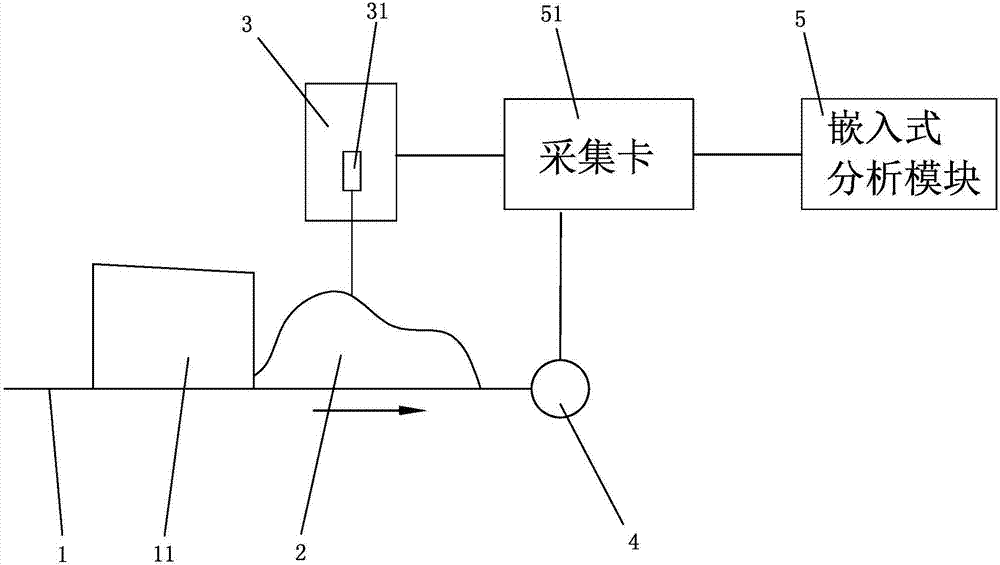

Quality measurement device and method

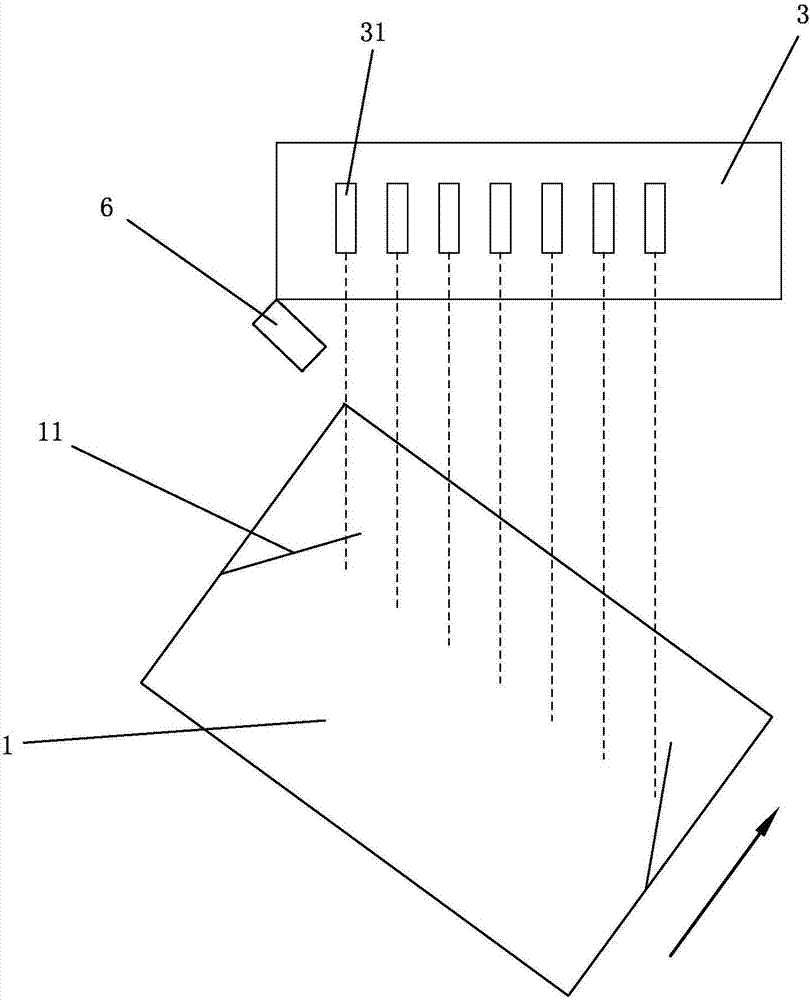

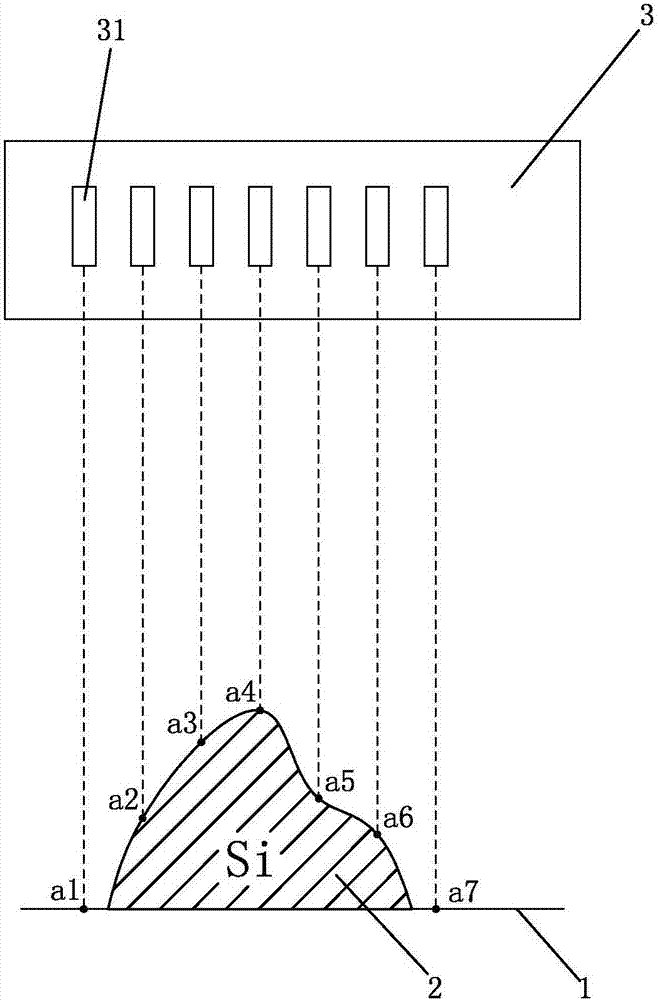

PendingCN106895897AReal-time measurementNo measurement errorWeighing apparatus for continuous material flowSpeed measurementLaser ranging

The present invention discloses a quality measurement device and method. The device comprises a conveyor belt, a laser range finding module, a speed measurement module and an embedded analysis module. The speed measurement module is configured to measure the travel speed of the conveyor belt; the laser range finding module comprises a plurality of laser range finding sensors being in linear arrangement at intervals, the laser range finding sensors perform range finding along the direction perpendicular to a conveying surface, and are distributed along the direction being perpendicular to the travel speed of the conveyor belt; and the laser range finding module is connected with the embedded analysis module through a collection card, and the speed measurement module is connected with the embedded analysis module. The quality measurement device and method are fast in measurement reaction speed, cannot not cause measurement error because of cheap material stack positions and more accord with the usage requirement in the actual production.

Owner:HUAQIAO UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com