Ultrasonic gas meter measurement data adjustment method

An adjustment method and a technology for measuring data, which is applied in the field of measurement, can solve problems such as detecting wrong waves, and achieve the effect of expanding the range and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

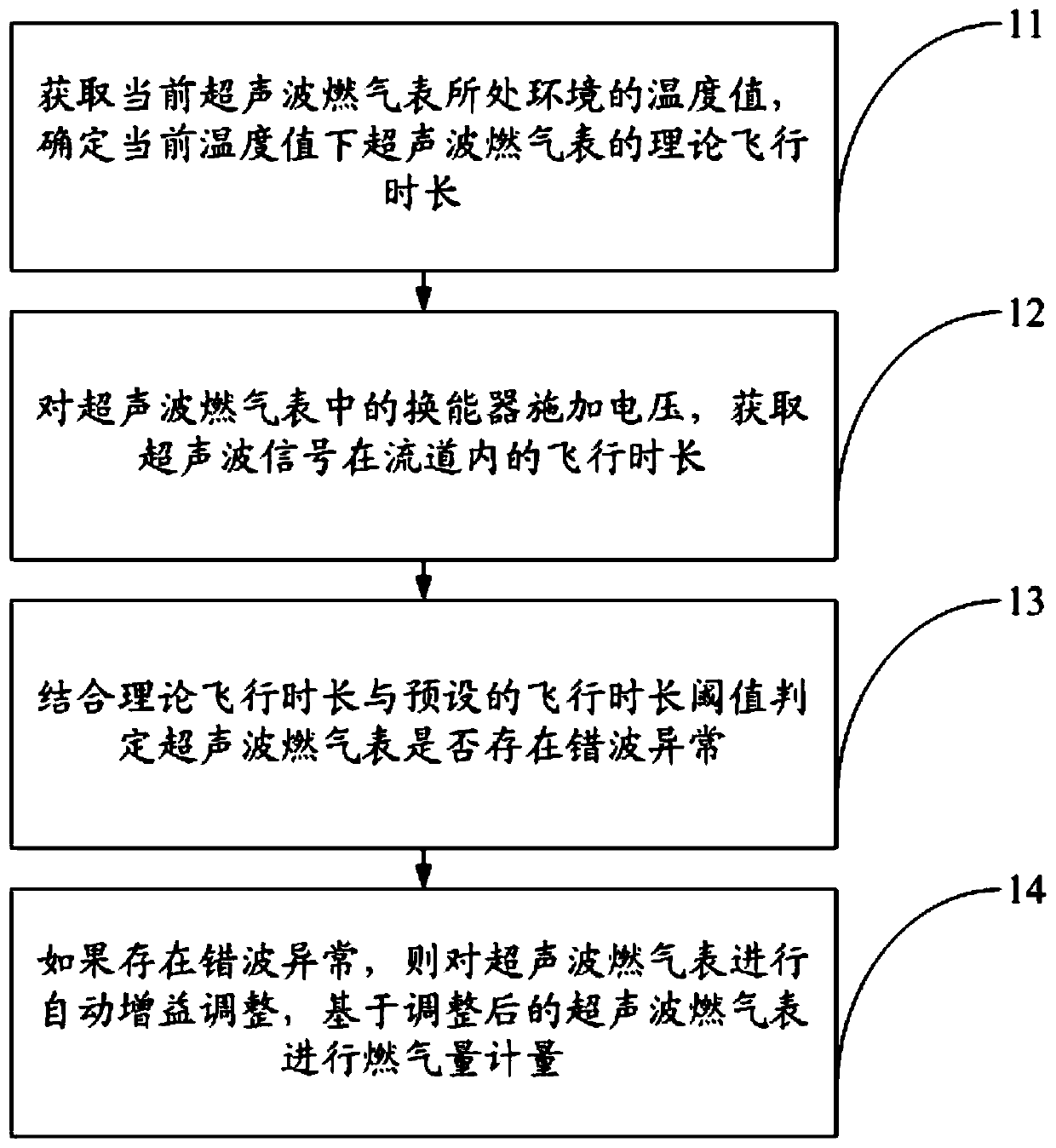

[0042] The present application provides a method for adjusting the metering data of an ultrasonic gas meter. The ultrasonic gas meter is provided with a storage unit that stores at least one historical flight duration in a detection cycle, such as figure 1 As shown, the adjustment method includes:

[0043] 11. Obtain the temperature value of the environment where the current ultrasonic gas meter is located, and determine the theoretical flight time of the ultrasonic gas meter under the current temperature value;

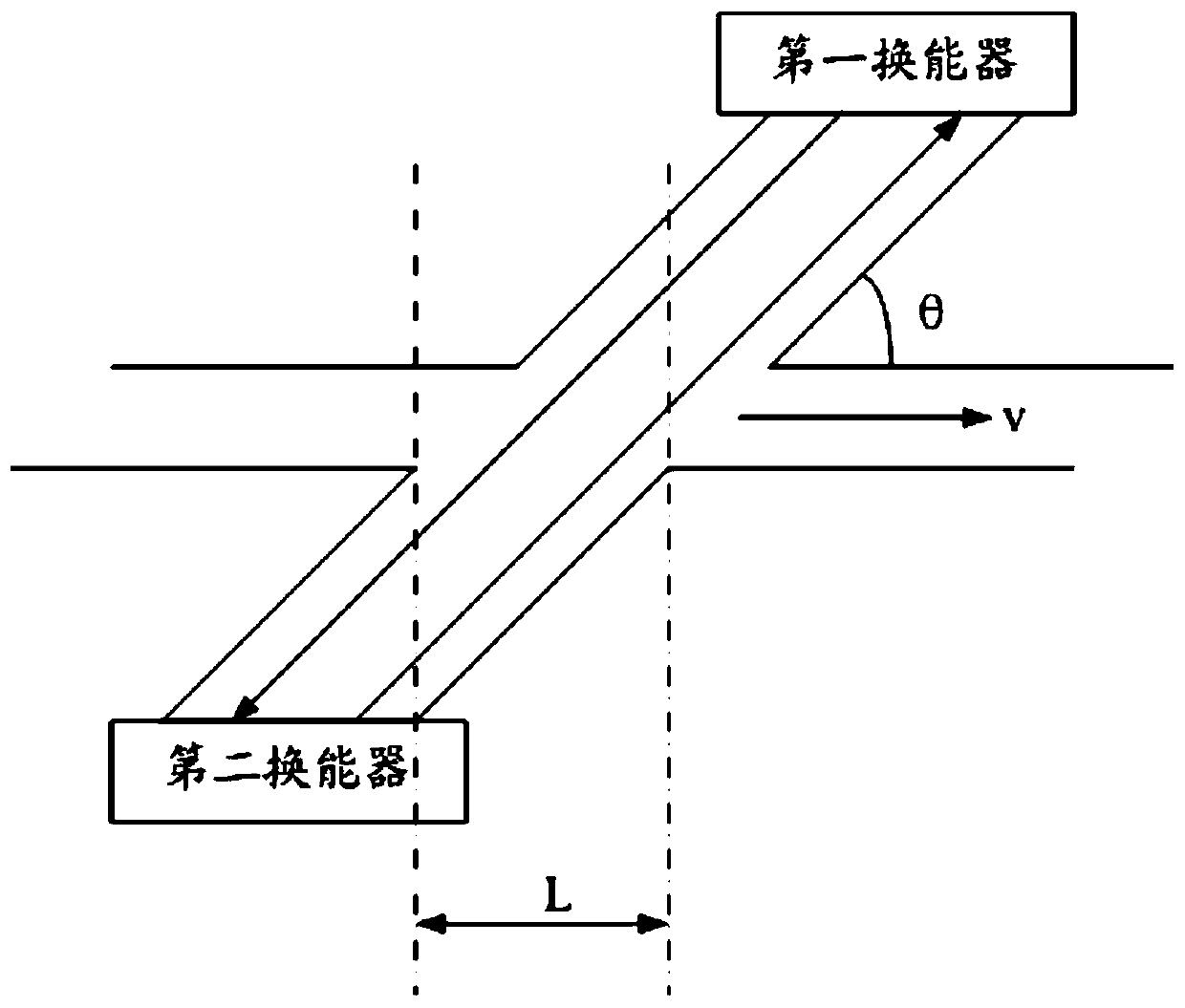

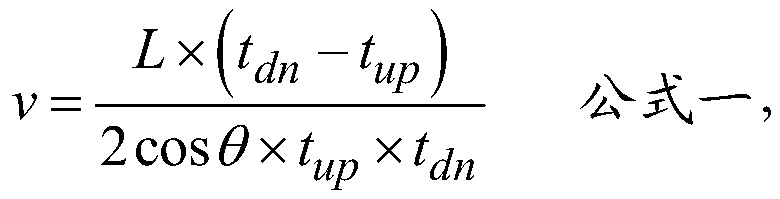

[0044] 12. Apply voltage to the transducer in the ultrasonic gas meter to obtain the flight time of the ultrasonic signal in the flow channel;

[0045] 13. Combining the theoretical flight time and the preset flight time threshold to determine whether there is an abnormal wave error in the ultrasonic gas meter;

[0046] 14. If there is an abnormal wave error, perform automatic gain adjustment on the ultrasonic gas meter, and measure the gas volume based on the adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com